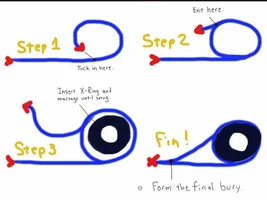

I just made a new X-Ring splice. Anyone see any potential? This came out of the 4:1 Bend Ratio thread, and the thought was that the splice would be stronger since the throat exit angle is less than normal.

View attachment 29969

Eric,

Don't know if I'm understanding it correctly.

Is it this?

Also, I do understand what you are saying about throat exit angle. But that has never been an area that would break in the testing machines though.

Interesting.

[Gotta love this new buzz; getting notified when someone adds to a thread I'm "watching"]

IF you are simply wrapping like my drawing above, can't the ring be shaken out? or is there never enough slack in the eye to ever do that?

That's cool if it can't be shaken out. Hope that is what you say.

I'll check back tomorrow night I hope.

IF they are secure, then you could maybe do a three ring in-line version, kinda a flexible version of my THT coming out. But unfortunately they might fold up on each other under load and diminish the friction, I'm not sure if they would or not. Plus they aren't matte finish like the new THT, plus are not as much aluminum to heat sink the heat away. But it might work! Just thinking out loud. Thanks.

Oh, on another topic, when I talked in the past about multiple rings for bend radius. It is likely more than that, I've brought it up a few times here and there when the topic comes up. It is also beneficial to rigging rope due to using a LONGER section of rigging rope when using multiple rings. DMM guy backed me up in 2012 at the expo when people were questioning 3 rings, verses two, verses one and arguing that it was all the same. DMM dude said, no, we found the same results in our cast thimble testing. Three of their little thimbles would not be the point of rope failure, but one or two thimbles was the location of rope failure in testing. And, it might not do much for "bend radius", but it is spreading it out over a longer section of rope. I personally do think three of the large (28x20) rings does improve bend radius some; you have to observe how they tweak in the break machine to understand. But using a "longer section" of rope is likely more beneficial and the main reason. My vocabulary and understanding exactly what bend radius meant was not that good. All I knew for sure was, three of the large 28x20 will never break the rigging rope. Two of the beast rings won't either.