LOL! Sí, hombre. Estoy bastante seguro.So any cordage larger in that splice configure would exceed the lips of the ring y no muy beuno?Que pasa?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

X-rigging rings

- Thread starter treebing

- Start date

Hey, X-Man, I just saw your article in Access & Rescue, Jan 2015:

I have to take issue with a couple of central points:

1) There is no such thing as a "non-friction block", as even the most efficient pulley would have no better than 95% efficiency and most are in the 85%-90% range.

2) All redirects multiply the force at the anchor, up to 2x for a theoretical frictionless device with at 180° bend in the rope - less of a multiplication for less acute angles and for more friction.

Well, the X-Rigging Rings (XRRs) were introduced to the arborist industry in 2012 by Xtreme Arborist Supply and they do just that. These are a low friction ring that the rigging rope runs through. When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block. When you have friction at a rigging point, you are lessening the force on one leg of the rope that is pulling on that rigging point...........................

I have to take issue with a couple of central points:

1) There is no such thing as a "non-friction block", as even the most efficient pulley would have no better than 95% efficiency and most are in the 85%-90% range.

2) All redirects multiply the force at the anchor, up to 2x for a theoretical frictionless device with at 180° bend in the rope - less of a multiplication for less acute angles and for more friction.

Hey, X-Man, I just saw your article in Access & Rescue, Jan 2015:

I have to take issue with a couple of central points:

1) There is no such thing as a "non-friction block", as even the most efficient pulley would have no better than 95% efficiency and most are in the 85%-90% range.

2) All redirects multiply the force at the anchor, up to 2x for a theoretical frictionless device with at 180° bend in the rope - less of a multiplication for less acute angles and for more friction.

Where's this article?

Stihlmadd

Been here a while

- Location

- Adelaide South Australia

There is no such thing as a "non-friction block"

Hey, X-Man, I just saw your article in Access & Rescue, Jan 2015:

I have to take issue with a couple of central points:

1) There is no such thing as a "non-friction block", as even the most efficient pulley would have no better than 95% efficiency and most are in the 85%-90% range.

2) All redirects multiply the force at the anchor, up to 2x for a theoretical frictionless device with at 180° bend in the rope - less of a multiplication for less acute angles and for more friction.

ha ha StihlMadd

Oh good golly Rescue Man !

Of course you have to have some issues with what I wrote, or with what anyone writes for that matter.

"..... and most are in the 85%-90% range."

Are you sure that's right?

Are you sure it's not 84.998799% - 90.989912% range of efficiency?

Blocks feel friction less to the worker, that is for sure and anything with that high of a range I'm probably going to continue to call frictionless even though you educated me.

"2) All redirects multiply the force at the anchor, up to 2x for a theoretical frictionless device with at 180° bend in the rope - less of a multiplication for less acute angles and for more friction."

I think I need more clarification as to what you are saying before I respond to this one. I will try to draw a diagram later so you can tell me if I got your information correct. (I need to get back to some work first, but I checked the buzz on my phone while eating some lunch and saw your post).

I don't mind you rescueman.

I had a writer in the arborist industry proof read my article, among others. You know what that writer said? In short, that this article was finally one that was understandable and not all jumbled up with technical jargon and numbers that tend to lose the reader. It was actually a relief to read instead of the normal talk over your head crap.

Rescue, I've been wondering, are you the same guy with gray/white hair and a beard that spoke up in my crane talk at TCIA expo in Charlotte, North Carolina? Who had a major problem with me showing a high line for a climber to work off of on a hollow tree? Kinda tried to turn the crane talk into climber and high-line talk instead? Because your personality seems extremely similar and there are not too many people like you.

Again, I don't mind you at all and I think you don't mean anything hateful, you just HAVE to get very detailed and exact. I will be happy to converse this with you on this public forum.

Heck, that is just maybe 1/3 of the article, wait till you read the whole thing.

Of course you have to have some issues with what I wrote, or with what anyone writes for that matter.

Are you usually this defensive or only when caught with your pants down?

Lol never mind keeping the gloves up but for everyones sake keep your pants upAre you usually this defensive or only when caught with your pants down?

Rescue,Are you usually this defensive or only when caught with your pants down?

I think others that have been long term members can tell you that I am being extremely nice and mild here. I really tried to explain that I'm not mad or upset at your post. I can even talk to you on the phone if you want and you'll see that I'm okay. I've gotten much more mellow with my age increasing and not as much of a dick as I was in the past.

Calling a block "frictionless" is technically wrong, I see your point, true frictionless would have to probably be a superconductor floating magnetic air "bearing".

I see now that I needed to say near-frictionless blocks so that the few people like yourself are okay with it.

Hopefully there aren't any larger "problems" with the article. But we shall see

I see now that I needed to say near-frictionless blocks so that the few people like yourself are okay with it. Hopefully there aren't any larger "problems" with the article.

The larger problem (no quotation marks) is the sentence "When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

You are absolutely multiplying force every time the load line is deflected over a change-of-direction element, whether X-ring or block. Some of that load multiplication is mitigated by the friction, which turns force into heat, but it's the angle of deflection which matters.

You describe your X-rings as "low-friction" devices, in which case the difference between an X-ring and a block is quantitative, not qualitative.

If there are only "the few people" like myself who don't ignore patently false information that can lead to disastrous outcomes, then we live in a strange world.

P.S. I haven't been in NC since 1990, when I went to NC Outward Bound for vertical rescue training and an Experiential Education conference.

The larger problem (no quotation marks) is the sentence "When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

You are absolutely multiplying force every time the load line is deflected over a change-of-direction element, whether X-ring or block. Some of that load multiplication is mitigated by the friction, which turns force into heat, but it's the angle of deflection which matters.

You describe your X-rings as "low-friction" devices, in which case the difference between an X-ring and a block is quantitative, not qualitative.

If there are only "the few people" like myself who don't ignore patently false information that can lead to disastrous outcomes, then we live in a strange world.

P.S. I haven't been in NC since 1990, when I went to NC Outward Bound for vertical rescue training and an Experiential Education conference.

I thought multiple points soften the angle to reduce the load because of the angles? Each point you go through obviously is touched by the rope so it sees some pressure/weight but isn't less over all hence the angle manipulation of complex rigging?

The larger problem (no quotation marks) is the sentence "When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

You are absolutely multiplying force every time the load line is deflected over a change-of-direction element, whether X-ring or block. Some of that load multiplication is mitigated by the friction, which turns force into heat, but it's the angle of deflection which matters.

You describe your X-rings as "low-friction" devices, in which case the difference between an X-ring and a block is quantitative, not qualitative.

If there are only "the few people" like myself who don't ignore patently false information that can lead to disastrous outcomes, then we live in a strange world.

P.S. I haven't been in NC since 1990, when I went to NC Outward Bound for vertical rescue training and an Experiential Education conference.

"When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

Doesn't this just mean if you put a chunk of log through a block you'll need at least equal friction to hold it making 2x the force on the rigging point.

But using an XRR in this case or even natural crotch adds friction so it takes less friction on the porti to stop it.

Should this not work out to slightly less force on the tie in?

The larger problem (no quotation marks) is the sentence "When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

You are absolutely multiplying force every time the load line is deflected over a change-of-direction element, whether X-ring or block. Some of that load multiplication is mitigated by the friction, which turns force into heat, but it's the angle of deflection which matters.

You describe your X-rings as "low-friction" devices, in which case the difference between an X-ring and a block is quantitative, not qualitative.

If there are only "the few people" like myself who don't ignore patently false information that can lead to disastrous outcomes, then we live in a strange world.

P.S. I haven't been in NC since 1990, when I went to NC Outward Bound for vertical rescue training and an Experiential Education conference.

Last one for now rescue man do you think X has a tricky malicious intent or do you think he wrote a small article and not a fully defended sourced scientific technical report?

I find some times there's lots I don't know and XRRs are fairly new but I try to learn and get out there and any time I've had a questions about anything xrr X has been a great help. He's actually spent a lot of his time to bring us these articles, xrr, so on and so forth I didn't know him 'when he was as much of a dick as he was in the past' but sometimes articles take liberties when summerizing for a magazine, it's not a certified legal document.

All that aside we'd all be glad I'm sure to see the articles from you trying to forward the industry as well. Don't feel like we only read X's

I thought multiple points soften the angle to reduce the load because of the angles?

Each change of direction reduces the line load by the "pulley" efficiency ratio, but any line angle less than 120° will multiply the average (line in, line out) force at the anchor resultant vectors (big arrows).

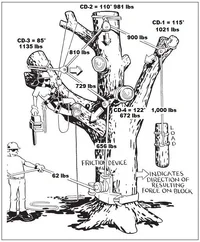

Mark Chisholm explains this well in his article (archived on this site), Engineering a Tree Removal. One major advantage of this kind of complex rigging is that it forces the multiple stems toward each other rather than away from the primary stem (kind of like temporary cabling).

I've taken his "figure 5" and added the line loads and resultant Change-of-Direction (CD) anchor point loads - in this case assuming 90% efficient blocks and a 1¼ wrap around the GRCS. Note that two blocks (1 and 3) experience more force than the actual load, including the 3rd one which had the initial load significantly reduced by block friction (it has the smallest angle).

I'd be interested in knowing what the "pulley efficiency" is for an X-ring.

That can be easily determined by hanging a known weight from a line with a 180° turn through an X-ring (or 2 or 3), and measuring the force on the other end of the line with a strain gauge (dial or digital crane scale).

That can be easily determined by hanging a known weight from a line with a 180° turn through an X-ring (or 2 or 3), and measuring the force on the other end of the line with a strain gauge (dial or digital crane scale).

Mark13y

New member

- Location

- Rock Creek, Ohio

That's cool to see the numbers along with everything, What would those be on x-rings

The larger problem (no quotation marks) is the sentence "When you are adding friction to a rigging point, you are not multiplying the force on the rigging point like with a non-friction block."

You are absolutely multiplying force every time the load line is deflected over a change-of-direction element, whether X-ring or block. Some of that load multiplication is mitigated by the friction, which turns force into heat, but it's the angle of deflection which matters.

.

OH ! I think I see the problem now.

I was trying to say that devices that have more friction than blocks don't multiply like blocks. Like, not as much as blocks. I should have had YOU edit it, you probably could have worded more proper for sure.

All I know is real world results and try to describe them. I know they are different, I SEE the results comparing rigging with blocks for most of my career to rigging with rings and other friction devices.

Rigging points don't flex as much and spars don't shake as much. I thought this could be described as it doesn't multiply the force like a block does.

Also redirects change the downward force on the final rigging point and I still think I don't know what you are saying here yet.

I gotta do some family stuff and will check back in later.

New threads New posts

-

test

-

-

If DMM made more carabiners that locked on a ring like the Revolver

- Started by Bill_N

- Replies: 5

-

-

-

-