@southsoundtree The meaning for you is that you spend ten less keystrokes of your life typing my handle than I spend typing yours. Ever wonder why anyone hardly ever tags you?

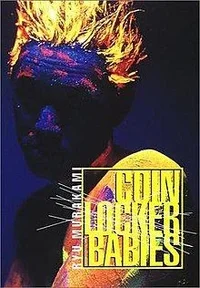

@craneguy1 Cheese, well, at least that's better than Coin Operated Locker Babies, which is something horrible that I just discovered while googling colb... Personally, I think that all should be Join Eperated Focker Fabies GU.

.

.

.

.

.

.

.

.

@JeffGu

@craneguy1 Cheese, well, at least that's better than Coin Operated Locker Babies, which is something horrible that I just discovered while googling colb... Personally, I think that all should be Join Eperated Focker Fabies GU.

.

.

.

.

.

.

.

.

@JeffGu