Can be installed and retrieved from the ground....

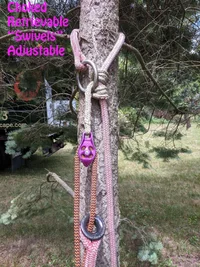

SRT setup:

View attachment 52309

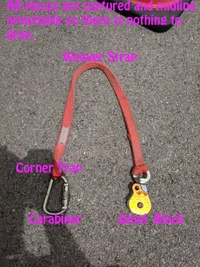

DdRT setup:

View attachment 52310

I like the ROOK pulley, but it's redundant in this setup, with the RE swivel shackle. It just happens to be the pulley I like best on it. I usually put another throwline through the pulley during installation so I don't have to drag the climbline through the crotch, then pull the rope through the pulley. On retrieval, I usually pull the rope back out and just bomb it out of the tree, or use the climbline to pull the throwline back through the pulley so I can ease it to the ground, if there is concrete or targets.

In SRT configuration, I have to pull the climbline through the crotch, but the kernmantles I use don't seem to mind, since the rope isn't loaded.

It installs very much like a ring-and-ring friction saver, with a couple of extra steps and things to keep in mind. The retrieval line is attached during installation, and I use either heavy throwline or 1/8" cordage for that.

I've even made a rigging version of this thing using an OmniBlock 2.6 and a really big ring. It's so heavy, I have to use a throwline through the pulley on retrieval because it would probably kill me if it landed on my head.