Re: Whole Tree Chipper Two Man Minimum Rule Adopti

[ QUOTE ]

I mean industrial sawmill blades are so expensive.

And the down time when one is damaged drains so inuch profitability from the mill.

Whereas treeworkers?

A dime a dozen, right?

jomoco

[/ QUOTE ]

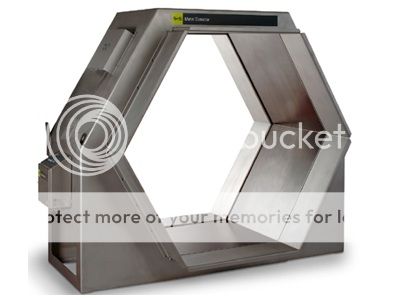

Very different application, the chipper industry has had a very hard time adding electronics. Look at vermeer, they lost a lot of clients when they added the knee bar to their chippers. Not because people were not concerned with safety but because the early models just didnt work. I saw a bunch of machines field rigged so the crew could get thru the day, this often had the effect of bypassing other more basic safety features, creating a much bigger problem.

Your design is a good start in the right direction, is not the answer. Too many problems.

The infeed tray of a chipper is about the most abused area of any tree companies fleet, creating a sensor in that area and securing it to a non metallic spacer would be very challenging, then make it last 10,000 hrs+

The metalic gloves is definitely a deal breaker, crews wear many different types of gloves depending on the weather, material, and tasks they are doing, often changing them throughout the day. There is no such thing as a dedicated chipper opp (at least not on any crew I have worked on) groundmen, climbers, crane opps, log truck drivers, even salesmen pitch in chipping when needed. Having special chipping gloves would be too cumbersome to be practical.

It doesnt do anything to address the "feet first" chipper accidents from kicking material in.

I really think you are wrong to think that the manufactures don't want to some this problem, the first company that comes up with a system that makes it almost impossible for a worker to go thru a chipper will make a fortune selling the rights to the other guys. But the system has to work on the real world, safety features are great on paper but if they don't work in the field, and crews are forced to bypass them to get the job done they are useless.

Comparing the two man requirement to a chain break doesn't make any sense. They aren't even in the same ballpark.

I would use osha requirement for crane work near energized conductors, a second qualified person on site in clear view of the wires and in communication with the crane opp.

Why not propose a standard for when someone can solo hand feed a chipper and when they need a second person?

Maybe "if you can safetly feed the material inyo the feed roller with one hand leaving the second hand on or near the safety bar, solo opperation is permitted, otherwise you need to cut it into manageable sections or get help from another"

Something along those lines, there are so many situations where one person chipping not a hazard, and only a few where it is. I object to a blanket regulation that would prohibit common safe operations.

You asked why anyone would do pruning with a "wtc", we dont buy small chippers, our smallest is a 1390 15" machine which we use for line clearance. The cost of ownership isnt drastic enough between that an a smaller machine to justify getting something we cant use for multiply tasks, they can prune and do removals efficiently without changing equipment.

Regulation that would just hurt companies that invest in equipment that makes their employees jobs easier doesnt make sense.

I totally agree with everyone before me here who said we need better enforcement, not more rules. We work in an industry where hardhats are not worn in most small companies. More educational material and training would hurt.

You are all passion on this one, listen to some of the people who spoken up about this. I take safety dead seriously, I am all for saving lives and making our industry safer, but this is the wrong way.