Well, not really.

What im asking about is the internal tension of the rope.

Ignoring the crotch, and how much tension is there in the rope at that magic spot where two legs of rope suddenly become the same thing?

I take one side of my rope off my MRS system and tie it to the tree. The branch my rope is over "feels" like im pulling on it harder. Does my rope "feel" like its getting pulled apart at the branch with 2x the force of my body weight?

Now i send up a runninbowline to the same branch and sit on the same single leg of rope. Is there now less tension inside the rope? There is less force on the branch, but im pulling the rope apart just as hard, the end still is immobile.

Another situation....a loop runner is pulled apart @ 24 kN. Take the same exact webbing and stitch it into an eye2eye (assuming the stitching = strength of webbing) , bend it around a round, immobile anchor and pull apart one side. Does it take 12 kN?

I think I understand what you’re trying to say. Let’s take the aspects of friction and pulley diameter out of it, to make things simpler. What you’re asking is if in MRS the stress based at your TIP is equal to, less than, greater to, etc than SRS through only one TIP with a basal tie.

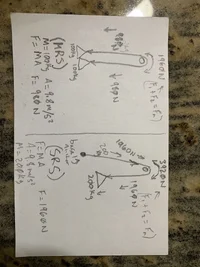

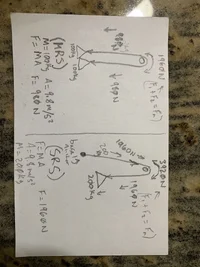

Since people seem to not understand what an example is, I’m going to use kg this time. All of the figures that have been shown, in terms of physics are correct, except for the one I commented on earlier, so keep that in mind.

I made a rough sketch as to how to determine the force on the rope at your TIP

assuming no friction and disregarding angles and bend radius of the rope.

At 200kg, a climber using an MRS system places 1960N on their TIP while hanging. This is the same force placed on your line at that point.

At 200kg, a climber using SRS with a basal anchor system places 3920N at their TIP while hanging, again, this is the force placed on your line at that point.

Honestly though, in order to get the true force being applied, you would have to take into account the radii of the TIPs and any angles caused in the system. It starts to get much more complicated, but that being said, increasing the size of your TIP will put less stress at that point, while acute angles in a system will decrease the force as well