Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The difference between logging and Suburban Tree Work

- Thread starter Daniel

- Start date

Mick Dempsey

Carpal tunnel level member

- Location

- France

It seems to me the skill level needed to fell trees in the desired direction with a rope and a machine pull is miniscule in comparison to doing it from the bottom with wedges etc.

Speaking as a rope and machine sort of guy.

Speaking as a rope and machine sort of guy.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

Absolutely, much easier... it's a much different game...It seems to me the skill level needed to fell trees in the desired direction with a rope and a machine pull is miniscule in comparison to doing it from the bottom with wedges etc.

Speaking as a rope and machine sort of guy.

The rope allows a lot more possibilities... but you can push the limits with either method.

Mick Dempsey

Carpal tunnel level member

- Location

- France

I guess, if you want to ‘push limits’ for whatever reason.

I think if I have a point, it’s that discussing hinge dynamics and all that is a bit superfluous if there’s a 100hp plus tracked loader telling it what to do.

I think if I have a point, it’s that discussing hinge dynamics and all that is a bit superfluous if there’s a 100hp plus tracked loader telling it what to do.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

That's how I made a living for 20 years... dropping trees that others were going to rig or crane out... that's bidding against east coast fallers, which is far differentthanthe west coasts arbs.. 20 years ago most didn't even understand the basics of how and why to cut a clean notch... these guys' grandfathers weren't loggers... somewhere around 06, one of the top log haulers around here told me I was the only one using directional control to drop whole trees. Everyone else was rigging them down to a stick that couldn't hurt anything.I guess, if you want to ‘push limits’ for whatever reason

It was a good gig for a lot of years. Their skills have improved significantly since everyone and their grandmother is putting out how to videos. You certainly weren't going to learn how to drop trees from the ISA or TCIA..

For example

I showed just the basics of how to use the plate cut to add height to the front of the hinge and taper the back cut etc to a climber that I worked with in the mid 2000s... probably less than a year. He then got a job with one of the larger contractors in the market, running 50 to 60 guys in the field. He assured me that he was by far the best faller in the company.

Even to this day I regularly see bypass face cuts on logs and stumps. Many still don't understand the basics... That's not bragging... it's just the truth.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

This one saved the client over $5,600 and saver her 2 evergreen that they were going to have to remove to get a crane in there.

Falling that tree was a lot safer than putting a climber anywhere near it.

That's why to push the limits

Falling that tree was a lot safer than putting a climber anywhere near it.

That's why to push the limits

Last edited:

Matias

Been here much more than a while

- Location

- Butte County

it's not what you say, but how you say it duderinoThat's not bragging... it's just the truth.

- Location

- Retired in Minneapolis

Wait…you claim that in 2006 you were the only one in your market who was flopping whole trees?

I’m calling Rubbish and Horn Blowing

Here in the northern part of flyover land I was taught in years previous to this century to cut the tree to fit the flop zone

Your world vision sure doesn’t line up with what I was seeing and been taught for years

I’m calling Rubbish and Horn Blowing

Here in the northern part of flyover land I was taught in years previous to this century to cut the tree to fit the flop zone

Your world vision sure doesn’t line up with what I was seeing and been taught for years

evo

Been here much more than a while

- Location

- My Island, WA

That and ripping codom unions for felling.

Matias

Been here much more than a while

- Location

- Butte County

like putting a ripping cut in the union to sever the fibers, but leaving them in place, or for felling at least one side off prior to dropping the stob?That and ripping codom unions for felling.

evo

Been here much more than a while

- Location

- My Island, WA

I donno, He just claimed he invented ripping vertically down a tight union and bore cutting the back cut from spurs 5' off the ground. Sumthin about preventing barber chair on ash.like putting a ripping cut in the union to sever the fibers, but leaving them in place, or for felling at least one side off prior to dropping the stob?

Pretty consistent claiming to 'invent' a tried and true method for making sure fibers are severed when felling a bifurcated tree in two parts away from the inclusion.

Ditto with gutting the center of the hinge out, that has been in the Stihl saw manuals from yesteryears. I know of no fallers that drag around a 48"+ saw into the woods. Those who do, frequently have to use a pilot saw with a shorter bar to get the horizontal kerfs started as the big big bars have so much weight and flex they will throw the chains when held horizontal.

post #50 and #58

Last edited:

Matias

Been here much more than a while

- Location

- Butte County

HAAAAHAHAHAHA! I forgot about that part. I thought you were talking about some mentor from when you you were a wee lad.I donno, He just claimed he invented ripping vertically down a tight union and bore cutting the back cut from spurs 5' off the ground. Sumthin about preventing barber chair on ash.

Pretty consistent claiming to 'invent' a tried and true method for making sure fibers are severed when felling a bifurcated tree in two parts away from the inclusion.

Ditto with gutting the center of the hinge out, that has been in the Stihl saw manuals from yesteryears. I know of no fallers that drag around a 48"+ saw into the woods. Those who do, frequently have to use a pilot saw with a shorter bar to get the horizontal kerfs started as the big big bars have so much weight and flex they will throw the chains when held horizontal.

post #50 and #58

TreeCo

Carpal tunnel level member

Wait…you claim that in 2006 you were the only one in your market who was flopping whole trees?

I’m calling Rubbish and Horn Blowing

Here in the northern part of flyover land I was taught in years previous to this century to cut the tree to fit the flop zone

Your world vision sure doesn’t line up with what I was seeing and been taught for years

Daniel makes Walter Mitty look like an amateur.

davidwyby

Branched out member

- Location

- PNW to SoCal

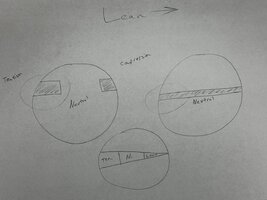

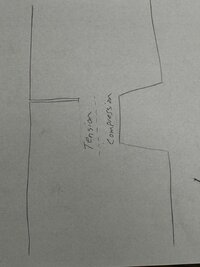

@Bart_ has a point. Remove wood from the center where it is useless (unless the outside corner is compromised) and add it to the outside corner in tension.

More engineering than treeing but a very interesting bunch of food for thought.

10:15 if you want to skip ahead.

More engineering than treeing but a very interesting bunch of food for thought.

10:15 if you want to skip ahead.

davidwyby

Branched out member

- Location

- PNW to SoCal

...unless the loader is pulling to the lay and there is significant untethered side lean...then the (tension side) hinge better hold, and or the loader go real fastI guess, if you want to ‘push limits’ for whatever reason.

I think if I have a point, it’s that discussing hinge dynamics and all that is a bit superfluous if there’s a 100hp plus tracked loader telling it what to do.

davidwyby

Branched out member

- Location

- PNW to SoCal

davidwyby

Branched out member

- Location

- PNW to SoCal

Flaw in the thick hinge theory?

More wood in compression means it cannot be compressed and it will act as a fulcrum to break the rear/tension wood sooner. Theoretically…

More wood in compression means it cannot be compressed and it will act as a fulcrum to break the rear/tension wood sooner. Theoretically…

evo

Been here much more than a while

- Location

- My Island, WA

Obviously species dependent, but heart wood is more brittle and doesn’t contribute to hinging nearly as much as sap wood.

Yet some need all they can get.

Yet some need all they can get.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

It's not about the qualities of the wood fiber as much as it is the position of the fibers which have leverage to fight the side lean on the corners... leave just enough wood on the compression side to make sure it doesn't settle, take out the middle, and leave the maximum amount on the tension side that you can, given the amount of pull you have to trip the fall.Obviously species dependent, but heart wood is more brittle and doesn’t contribute to hinging nearly as much as sap wood.

Yet some need all they can get.

Last edited:

evo

Been here much more than a while

- Location

- My Island, WA

While you can go with less in the middle you must increase the thickness. I haven’t found gutting the center of the hinge as having any more or less benefits other than being able cut with s shorter bar.It's not about the qualities of the wood fiber as much as it is the position of the fibers which have leverage to fight the side lean on the corners... leave just enough wood on the compression side to make sure it doesn't settle, take out the middle, and leave the maximum amount on the tension side that you can, given the amount of pull you have to trip the fall.

Around here our big bars are typically 28-32” wrap saws and cutting the bad side first. Really no need to cut the guts out as we all have bigger setups on the truck. Out in the back 40 is where the tricks come out to play…

New threads New posts

-

test

-

Free CEUs: February 05 & March 05 - 'Urban Forestry Today' Webcasts @ Noon (Eastern)

- Started by UFT

- Replies: 0

-

-

-

-

-