JeffGu

Been here much more than a while

- Location

- Osceola, Nebraska

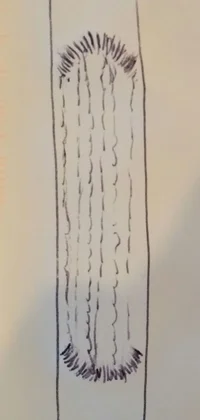

Damn... the patterns marked 30% and 33% are the ones I see the most on stuff coming out of China... but, the bar tacking marked 66% is what I see on most quickdraw slings. I've seen the 70% and 100% patterns on USA made harnesses. Interesting. I'd really like to get a machine that can handle these materials. Clearly, @Pelorus is the man to talk to... right, Dave? You don't care if I call you up and bleed your brain out for useful information?