ghostice

Been here a while

Moss for whatever it's worth I think you've done a great job documenting your sewn eye efforts and sharing for all. Thanks to you. Whether we use 'em for rigging or whatever, it pays to have a system.

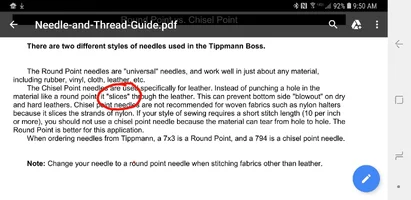

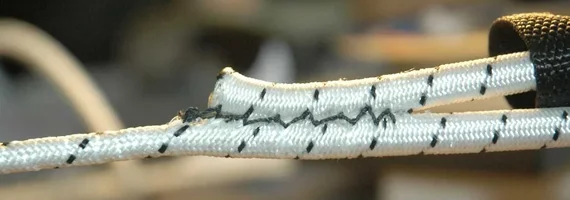

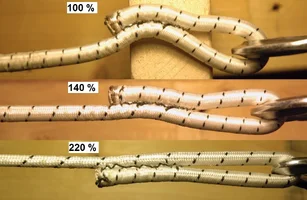

On that note, I am still left wondering a bit about 1) consensus on "ideal" threads for the stitching - including what is used in machines and what's better for hand stitching - size more than the material? And also the needles - esp. with regard to tearing of the rope thread material during stitching. 2) a stitching pattern - I know there are comments on this earlier on this thread, just wondering on where everyone kinda landed - Richard what does your computer say in the machine setup maybe?

Also, in what may be due perhaps to a pre-New Years dollop of rum and eggnog, has anyone thought of something like a small hand drill press stand thingy being modified for driving a needle and then having a rope holder and pad on the bottom for allowing the needle to pass thru the rope. Might it be possible to slowly sew a more exact pattern by flipping the rope holder/ clampy thing back and forth - to pass the needle thru dead vertical and then pull the thread (if you're not doing a lock stitch). There's lots of these little drill press like things on the web.

As for open minds Richard, it never changes. In the London Museum of Science and Technology you can see the original devices Joseph Lister used when he invented aseptic techniques and using carbolic acid aerosol spray for surgical procedures, to try and get surgical infection rates down. What they don't say is that he was, or was almost, drummed out of the Royal College of Surgeons for the heresy of his work in the day. Progress meets immovable object is as old as man (we should probably still feel sorry for poor old Grogg the Caveman when he invented the stick as a weapon . . . everybody knows you can only use rocks).

On that note, I am still left wondering a bit about 1) consensus on "ideal" threads for the stitching - including what is used in machines and what's better for hand stitching - size more than the material? And also the needles - esp. with regard to tearing of the rope thread material during stitching. 2) a stitching pattern - I know there are comments on this earlier on this thread, just wondering on where everyone kinda landed - Richard what does your computer say in the machine setup maybe?

Also, in what may be due perhaps to a pre-New Years dollop of rum and eggnog, has anyone thought of something like a small hand drill press stand thingy being modified for driving a needle and then having a rope holder and pad on the bottom for allowing the needle to pass thru the rope. Might it be possible to slowly sew a more exact pattern by flipping the rope holder/ clampy thing back and forth - to pass the needle thru dead vertical and then pull the thread (if you're not doing a lock stitch). There's lots of these little drill press like things on the web.

As for open minds Richard, it never changes. In the London Museum of Science and Technology you can see the original devices Joseph Lister used when he invented aseptic techniques and using carbolic acid aerosol spray for surgical procedures, to try and get surgical infection rates down. What they don't say is that he was, or was almost, drummed out of the Royal College of Surgeons for the heresy of his work in the day. Progress meets immovable object is as old as man (we should probably still feel sorry for poor old Grogg the Caveman when he invented the stick as a weapon . . . everybody knows you can only use rocks).