David, can you post the all the mods in your most recent update? Mostly, it seems you've shortened the uppers, but is that the hinge point length?

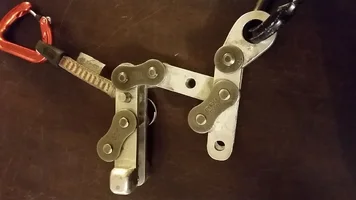

Eric, I have done several small things but the big change, and it is a big change, was shortening the top arm. As this picture shows, I redrilled the upper pivot link hole bringing everything closer to the spine. The hole spacing and length of the top arm is now identical to the lower arm. Look how much that lowered the top arm. It is now always very close to the release point. The top link still has the same amount of friction but with the shorter length of lever it exerts less control over the BDB while being easier to release because the leverage now favors the release side of the arm. You can also tell by the reduced bend of the rope at the top link and the increased angle at the spine, that more load is being carried by the spine. This is good as the spine can handle more heat and dissipate it more effectively than the steel links. Due to the increased load on the spine, I not only made it symmetrical so it can be rotated to 4 wear surfaces, I made it from stronger 7075 T6 aluminum. The only other changes were a loading notch cut in the top arm and carving out some inside material on the arms to allow the fatter Vortex a little more room.

Please do remember it is winter here in Montana and my altered BDB has not seen enough hours yet for a full on field report.