I saw more and more mini or mini-self-propelled chipper units on the show floor at Expo than in years passed. Maybe I’m just noticing that and it’s always been? Anyway, I dig the model you’re under. I’m in a similar situation, but maybe a bit more equipment intensive for a few reasons that compounded. Basically just doing as much as possible under CDL and through a 36” gate as possible.I have definitely pondered a high-lead tether to lower the machine down a steep slope, it isn't as all terrain as the MT100 mini skid. I also installed the factory lifting hooks and I am keeping an eye out for a job where craning the shredder into an enclosed yard makes sense.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What’s Your SMALLER Equipment Setup?

- Thread starter climbingmonkey24

- Start date

Thanks for reading my long winded posts. It does seem like the track chipper/shredder concept is catching over here in the states, definitely driven by European manufacturers. I looked at many different options before deciding on Eliet. Kinda like your Hoeflon, I don't think there is a better option pound for pound. 34" and only 1100lbs wet makes it super unique in the market. It would be a great machine to load into a Transit/Sprinter type van as well for a very self contained and lockable tree vehicle.I saw more and more mini or mini-self-propelled chipper units on the show floor at Expo than in years passed. Maybe I’m just noticing that and it’s always been? Anyway, I dig the model you’re under. I’m in a similar situation, but maybe a bit more equipment intensive for a few reasons that compounded. Basically just doing as much as possible under CDL and through a 36” gate as possible.

macrocarpa

Branched out member

- Location

- Midwest

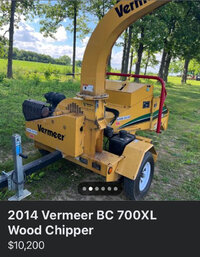

I’ve been seeing several of these chippers pop up this winter for around this price range with around 500 hours.

What do you guys think about this price range/machine for a small scale pruning operation?

What do you guys think about this price range/machine for a small scale pruning operation?

Attachments

Mike H

Participating member

- Location

- Boulder County

I have run a 6 inch Vermeer before. I rented one when my bc1400 was down. It was so frustrating that I returned it early.

If you have straight thin branches it is better than nothing. Prepare to cut apart every crotch. We just finished a Russian olive site clearance job for a builder. I would have gone crazy without two feed wheels crushing those hateful pieces. I am back to daydreaming about a bigger chipper again.

If you are hauling to an expensive dump site, the price for this machine is fair in my opinion. It just takes forever to feed a large pile. Good luck

If you have straight thin branches it is better than nothing. Prepare to cut apart every crotch. We just finished a Russian olive site clearance job for a builder. I would have gone crazy without two feed wheels crushing those hateful pieces. I am back to daydreaming about a bigger chipper again.

If you are hauling to an expensive dump site, the price for this machine is fair in my opinion. It just takes forever to feed a large pile. Good luck

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

Look for a Bandit with a 6x12" throat.

Honestly comparing a BC1400 to a 700 is apples and oranges. When you are used to bigger machines that weigh 2-3 times as much and have 2-3 times the horsepower, your not even in the same league.

I've never even used less than a 12" chipper in my life, and when I went from a BC1000 to a Bandit 12XP the productivity gains were huge in terms of reduced processing and so on, but I see plenty of people out running 6" Vermeers and they do just fine, you just need to know and accept their limitations. But yah, if you are used to 'big' machines, it will be frustrating. Still, its a hell of a lot better than no chipper.

I've never even used less than a 12" chipper in my life, and when I went from a BC1000 to a Bandit 12XP the productivity gains were huge in terms of reduced processing and so on, but I see plenty of people out running 6" Vermeers and they do just fine, you just need to know and accept their limitations. But yah, if you are used to 'big' machines, it will be frustrating. Still, its a hell of a lot better than no chipper.

Mick Dempsey

Carpal tunnel level member

- Location

- France

There is no point running a 200hp chipper to keep up with a guy up a tree and 1 or 2 guys on the ground on a prune or removal.

This side of the pond 35 to 50 hp (7 to 8 inch capacity) is enough to keep up with a climber under normal circumstances.

This side of the pond 35 to 50 hp (7 to 8 inch capacity) is enough to keep up with a climber under normal circumstances.

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

A BC700 with 6x8 throat would be much better than a bc625 with 6x6 throat.

Hard to compete with medium or large removal jobs, but small removal and pruning, with sharp knives and anvil would be useful.

Probably good enough resale value.

I think, at least older Bandits have 35hp/ 6x9" throats, with an ad showing a new 6" Bandit at 6x12" with 25 or 44hp engines.

Might be with checking rental yards to see if they are replacing and BBs.

Hard to compete with medium or large removal jobs, but small removal and pruning, with sharp knives and anvil would be useful.

Probably good enough resale value.

I think, at least older Bandits have 35hp/ 6x9" throats, with an ad showing a new 6" Bandit at 6x12" with 25 or 44hp engines.

Might be with checking rental yards to see if they are replacing and BBs.

Tree-Taylor

Branched out member

- Location

- Canada

A larger chipper with bells and whistles will be more efficient. This has been stated over and over. A crane is also generally more efficient than a wood dolly...

If you're curious about a 6 inch chipper I would rent a similar model and use it for your typical workday. Figure out what your payments will be for the machine then decide if it makes sense for your business model. Don't forget that more cutting equals more wear and tear on your equipment and your body.

If you're curious about a 6 inch chipper I would rent a similar model and use it for your typical workday. Figure out what your payments will be for the machine then decide if it makes sense for your business model. Don't forget that more cutting equals more wear and tear on your equipment and your body.

I think all I could reiterate is I would prefer the in-feed opening of a Bandit over a Vermeer. Having owned a Vermeer BC935 (9x9 opening) but also operated an old Bandit 90, the Bandit has the upper hand IMO.

You also don’t necessarily HAVE to chip everything. Reduction is nice, but perhaps you can find an outlet for skinnier wood and larger logs alike.

You also don’t necessarily HAVE to chip everything. Reduction is nice, but perhaps you can find an outlet for skinnier wood and larger logs alike.

Not trying to argue or anything, pretty sure we all agree Bandits tend to be superior to Vermeer's pretty much universally. When buying used chippers, choice and availability is usually pretty limited though, and since Vermeer's like that BC700 make up the bulk of the units at rental yards, they tend to be far more common on the used market. Not to mention a "similar" 6" Bandit would probably be closer to $20k than 10.

True, and hopefully something like that BC700 wouldn’t be overloaded with proprietary parts made of unobtanium? I do hear tough conjecture about newer Vermeer units being difficult to fix due to part availability.Not trying to argue or anything, pretty sure we all agree Bandits tend to be superior to Vermeer's pretty much universally. When buying used chippers, choice and availability is usually pretty limited though, and since Vermeer's like that BC700 make up the bulk of the units at rental yards, they tend to be far more common on the used market. Not to mention a "similar" 6" Bandit would probably be closer to $20k than 10.

Merle Nelson

Been here much more than a while

- Location

- SF Bay Area, CA

Buying used and working within a budget can dictate choices that a person might avoid otherwise.

Separately but interesting to me, here in The Bay Area of CA I used to see mostly Vermeer towed behind chip trucks and forestry trucks. Now it is almost all Bandit. Surprises me to see such a huge change in the space of 10 to 20 years even if it's absolutely what I would do too. Ohh, rental yards made the same shift.

Separately but interesting to me, here in The Bay Area of CA I used to see mostly Vermeer towed behind chip trucks and forestry trucks. Now it is almost all Bandit. Surprises me to see such a huge change in the space of 10 to 20 years even if it's absolutely what I would do too. Ohh, rental yards made the same shift.

Serf Life

Been here much more than a while

- Location

- Maine Island

Tree-Taylor

Branched out member

- Location

- Canada

X-SERIES™ | Wood Chippers SKARPER®

SKARPER® X-SERIES™ compact wood chippers: Precision-engineered for arborists. Unmatched speed, power, durability, safety, and cutting-edge features elevate your wood chipping tasks.

Looks like Skarper released their new line of compact chippers.

The height on the big ones looks like it would be a pain if you had to feed much into it.

X-SERIES™ | Wood Chippers SKARPER®

SKARPER® X-SERIES™ compact wood chippers: Precision-engineered for arborists. Unmatched speed, power, durability, safety, and cutting-edge features elevate your wood chipping tasks.skarper-professional.com

Looks like Skarper released their new line of compact chippers.

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

Yes, but dragging brush to an access point is often harder, IMO.The height on the big ones looks like it would be a pain if you had to feed much into it.

A powered-capstan and a brake line could get that into/ out of some hard access places.

My chainsaw powerhead-powered Simpson capstan attached to the tongue would work well, I think.

I have many steep, waterfront properties to access. That means the drag is commonly uphill.

Treemuel

Branched out member

- Location

- Hancock, ME

New (to me) Bandit 150 and work rig. Looking forward to not loading and unloading my personal truck constantly and not always subbing out chipping. Won't be hauling any chips of course, but around here I can usually chip on site more than 50% of the time, not to mention plenty of other climbing only or no clean up jobs.

Serf Life

Been here much more than a while

- Location

- Maine Island

Congrats! What engine? Grab a prefilter like this, air filter stays clean 10x longer easily. https://northeastern-arborist-suppl...glass-filled-composite-precleane-4829755.html

United Ag and Turf seem to be the Bandit parts and service in Maine, bit of a hike for you though over to Union or Auburn!

United Ag and Turf seem to be the Bandit parts and service in Maine, bit of a hike for you though over to Union or Auburn!

New threads New posts

-

test

-

Free CEUs: February 05 & March 05 - 'Urban Forestry Today' Webcasts @ Noon (Eastern)

- Started by UFT

- Replies: 0

-

-

-

-

-