Break Testing the Hand-Sewn Eyes (long post warning):

Back story: I bought a

big box of mostly arborist rope from Atwood Rope Co (which I was very pleased with, BTW; their static 11mm climbing line is absolutely perfect for SRS) as I wanted some shorts for projects. Some of the rope I got was non-spliceable 12 strand with a parallel core and some was kernmantle static. I didn't really want to learn to sew eyes so I tried to find a local shop to stitch them for me. I tried marinas, canvas repair shops, shoe repair guys, etc. No one had a machine with enough lift to sew the rope and I understand the big tree supply outfits don't do it anymore. So, I found this thread (pun) and ordered a speedy stitcher.

Luckily, in the box from Atwood was a bunch of their micro and nano cord which is great thread and is already the right material, i.e. it matches the material the rope is made of. A quick call to a beekeeper netted me some beeswax and I was off. I met

@moss on a rec climb and came away thinking that he is total guru in this sport of ours so I wanted to follow his directions exactly.

I really love climbing trees but it's not my profession. I'm a mechanical engineer by education so I couldn't help but make a science project out of this. I also wanted to help the readers of this thread to know the limits of what we are doing and try to increase the information available to us going forward. I don't think fear is nearly as good of a decision metric as data is. With that said, please let this post inform you but continue to make your own life-safety decisions.

First I broke the thread I was using so I'd have accurate numbers for the calculations:

I got numbers for each type of thread. The thin nano cord (1/32" / .75mm) broke between 22 and 38 lbs depending on color. The bigger micro cord (3/64" / 1.18mm) was in the 70-78 lb range, again depending on color (more likely the tightness of the braid). Then I stitched up a prototype of what I'll make as a lanyard adjuster in the future:

No pre-compression on this one. This had a theoretical stitch strength of 3212/14kN lbs per eye (although the thread isn't actually in line with the load there is a component of friction too. This cordage happens to have a very slippery cover so I expect it to break below the aggregate strength. We can discuss this in another post. Others have found break strengths in the neighborhood of aggregate thread strength)

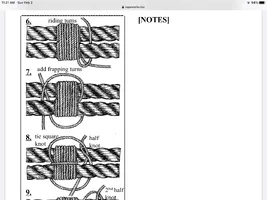

Note: This wasn't designed as a life-support component, just a test prototype. I believe it was mentioned in another post that the standard is 3360lb/15kN per eye minimum on hitch cord when both eyes are used (can anyone confirm this?) and we all know the Z133 standard says 5400lbs/24kN for all components in the climbing system. Time to test. First, a basket pull as it would be used:

I have access to overhead cranes and forklifts at work but our hanging scale only goes to 2000lbs. The hoist I was using is a 4000 lb unit. The basket pull to that weight showed no deformation in the stitching. Ok, time to double the stress:

No problem going to 2000lbs in a straight pull. You can see the thread which started perpendicular to the cordage is starting to look diagonal. This seems to be a good indicator of heavy loading, in my testing, and I'll use it during gear inspection going forward.

I took the scale off so as not to damage it and continued pulling. The piece I was lifting was a little over 5000 lbs of steel and I picked up the half I was connected to before the end (and the pin in the shackle) broke. That made quite a racket and brought some employees out to see even though it was break time. Oops. So, since I wasn't picking it up from the outside edge a (very) conservative estimate of the break strength would be 2500lbs or 78% of theoretical. See my note at the end of the last post about better instrumentation. Here's the carnage:

So, for my actual life-support version of this I'll use a stitch count that equals at least 130% of the desired strength because of the slippery cover. Likely more because I don't have the exact number it broke at. It was very encouraging, though, to see the fruit of my labor holding that much weight off the ground.

Now time for some bigger rope. This is nice, supple 12-strand from Atwood which holds a lovely knot but isn't spliceable (but I bet stronger) because of the parallel core. This is their 1/2" product but measures closer to 5/8". It's listed at 6000 break strength but their other products I've broken have broken above rated strength.

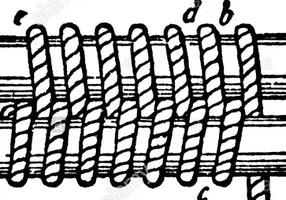

This time I used much thicker thread (3/64" / 1.18mm) as I wanted to test fewer, stronger strands. It was a challenge with a 190R-25 size needle but I got it done, this time with a little pre-compression:

Starting second pass:

Third pass complete:

I had a thought when this was done: Why are we stitching eyes? To create an eye in the rope. What are our other options to create an eye? Splicing and knots. If you can't splice the rope you're left with a knot. So, on non-spliceable rope my hypothesis is that our stitched eyes don't necessarily need to exceed the break strength of the rope but should exceed the break strength of a knot (typically 75% of the rope). This could make it a better option than a knot, as long as the stitching stays protected. With that in mind I tested my next sample to see if I could exceed the strength of a knot. I tied a bowline with a Yosemite finish in the other end of this test sample:

I'm at my picture limit so the next post will feature the test data. Stay tuned.