I'm sure X-rings have their place, but they seem to have a number of vulnerabilities.

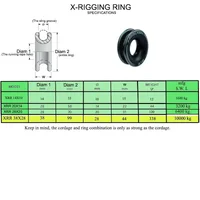

From the Tree Stuff website:

- X-Rigging Rings(XRR) are for rope rigging, NOT for climbing and life support use. The XRRs are very low friction, however, hard use and abuse could result in the ring becoming heated. Choose your sling material wisely in regards to what tasks the ring will be put through. Research your sling or rope material for degradation temperatures before choosing your cordage material.

- Do not use a single XRR as a terminal rigging point. The bend ratio with a single XRR and most rigging rope sizes does not meet best management practices in rigging. Consider triple ring use for terminal rigging. Use arborist blocks for heavy weights, long runs and when less friction is needed.

- XRR must be secured in a very tight professional splice. Do not splice if you are not qualified, slings can be purchased already complete with XRRs.

- Inspect your XRR and splice before every use. If the splice is loose enough for the ring to possibly come out, do not use.

- When an XRR is pushed to extremes, they will deform; the outside groove pinches inward and the XRR will become oval. Discontinue use if the XRR is ever deformed.

- IF the black Hard Coat Anodize is ever worn away, discontinue ring use; as the friction will increase and heat will increase.

I'm not much of a fan of hard-coat anodizing, as when it wears away it can leave a micro-edge that can cut rope fibers. Overheating may also be a problem if ropes are allowed to run too fast.

Oh my. I wrote all of those caution statements. Why? Two reasons: There are plenty of dump people out there and no matter how dump they are, I would personally feel awful and devastated if a person was killed with some product that I put out. That is the number one reason.

I don't want it for life support because what if a person used one as a friction saver ring in DRT and had the ring in a very loose eye. Then the climbing line was slacked and shaken and the ring fell out. AND they didn't notice it and repelled extremely fast; rope on rope and their friction saver rope burned through, they would fall.

These rings take heat way better than say a Stainless Steel large porta wrap. You will roll off smoke and glaze the rope on the porta wrap way before you get even a SINGLE large ring to glaze the rope. But, I don't know, some idiot might decide to lower a log 5,000 feet into the bottom of the grand canyon really fast. IF that happened, I'm sure the ring would be very hot and might melt the sling.

Personally speaking, I've used them many times as a friction saver for my climbing line. Should others do this? NO, officially.

IF I had a ring that was messed up due to muddy ropes or sandy ropes and it got a shiny aluminum patch worn past the anodizing, would I continue to use it? Yes, I would rotate the ring in the splice and keep using it. Should others do this officially ? NO

IF an XRR is deformed, then it was extreme forces, you are lucky that the sling didn't break. In almost all cases, the sling breaks first or at the same time. IF it didn't break, throw the sling away, because it was RIGHT there, right at the edge of breaking and will break soon.

The second reason to post all those overly cautious statements was to cover my butt, like all companies try to do.

Now:

I'm not much of a fan of hard-coat anodizing, as when it wears away it can leave a micro-edge that can cut rope fibers.

.

Rihiheeallly? (said in an Ace Ventura voice)

Let me explain what hard coat anodizing is in common language:

take aluminum and stick it in an acid bath and add electricity and other stuff.

the surface oxidizes, kinda like rust on iron.

The aluminum is penetrated and becomes the outer layer. It is part of the aluminum, plus it does build up some thickness on top as well

DO NOT think of it as paint, or powder coat or a coating.

You can NOT chip it off. You would have to grind it off, wear it away.

Wearing away with say muddy ropes is possible. Happened to me after using rings exclusively for three years ; then finally used them in heavy rain and muddy ropes with decent weights being lowered. Two little shiny patches on my beast rings.

Once the black hardcoat is missing, you are left with a shiny aluminum patch. You can feel a depression where the bare aluminum meets the hard coat. But believe me, it’s not like a paint chip. It’s like if you sanded down a paint chip with 3000 grit sandpaper and you think to yourself, “yeah, I think I feel an edge”.

Micro edge? I guess it could be called that. Causing a rope to fail? OH COME ON !

In a pristine testing environment with a new rope with no wear at all, then the rope pushed to breaking point in a machine with a tool that had a micro edge in the tool, then maybe. But I even doubt it then. It would rather break at the tightest bend.

From what I know, companies do aluminum tools in regular anodize because they can make pretty colors and it wears off quickly. Plus most companies can easily do this.

Things wearing out = more future sales AND pretty colors sell.

Hard coat anodize is difficult to get it right. Expensive due to this. Most businesses can’t get it right, they often make brown results and have to scrap it.

Hard coat can only come out BLACK. That is the only choice.