SRTsteve860

New member

- Location

- North West Connecticut

I don't know about that.

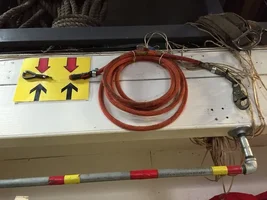

It looks like the two metal collars butt up against each other and the wire pulled out from both. Might give no warning at all even if it was clear heat shrink.

Tragic. Very sorry to hear about this.

While you might not be able to see the strands fraying perhaps, im confident the clear tubing would begin to collect rust residue as the strands corrode. After the tubing goes from nice and clear to being caked with rust that would be a good sign that the core is corroding severely. If not enough reason to retire immediately, then perhaps enough to warrant removing the covering and do a more thorough inspection.

-Steven