southsoundtree

Been here much more than a while

- Location

- Olympia, WA

Figuring on stable-braid. Haven't looked into it, really.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Anyone have these solo rigging techniques on video? I can kind of picture it but a video or some pictures would help

I think it’s great seeing older threads bumped that previously had some bright ideas and good conversation. I did see this thread before, but there’s probably a bunch of folks that haven’t.Would it be better to make this a new thread?

I think it’s great seeing older threads bumped that previously had some bright ideas and good conversation. I did see this thread before, but there’s probably a bunch of folks that haven’t.

It seems like you could incorporate either a cmi rope jack or RE aztec setup into a speedline system like this. I am not sure of the details of yours here, but I'm envisioning climbing to the top of the pine to set a omni 2.0 pulley, then installing speedline slings on the way back down to a hitch/rope jack or aztec pulley system, tightening it there, cutting, leaving the pulley and hitch in place, taking the rope jack up with you, jacking, cutting, etc. probably something that will illuminate itself while you're in tree, but have a backup plan.Small solo job coming up with a tall-ish straight pine, about 90' or so, but surrounded by some low shrubs and a wooden fence. Beyond the wooden fence, there is a natural/wooded area that debris can be placed in. Longest limb might be 12'-15' long or so, and maybe 5" dia. at the stem, judging from the ground.

I could sling/biner everything to itself, cut and let it hang, then dice and chuck. BUT, this seems like it could be a really good scenario for a climber-tensioned speedline. What do y'all think? The fence that needs to be cleared is just a couple feet from the bottom of the tree and only about 4' tall, and there are tons of anchor options out past that.

To that end, I've been exploring how to tension it in a way that causes me to not have to use a bunch of hardware that I have to remove and reinstall every time I move up the tree.

I think tensioning by hand with no MA will probably be enough for any size I'll want to cut, but I also have been trying to think about options for applying tension in scenarios where more is needed.

1) Tensioning with no MA and hardware (not pictured): bring the speedline itself up, around the tree at the desired anchor position, apply as much tension as I can pull into it, then tie it off back to itself.

2) Tensioning with no MA, but with a low-friction redirect: bring speedline up through sling/biner or ISC Rigging Rope Wrench anchored on tree, then tie it back to itself. This is the option I'm leaning towards since only one sling is needed on tree (for RnW). RnW will assist with tensioning by lowering friction and increasing efficacy of pull.

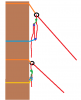

3) Tensioning with no MA, but with upper redirect and sling/biner/prussik below that for progress capture while tensioning (lower of the two setups shown below - with green little prussik).

4) Tensioning with 3:1 MA: too much crap in the tree, but I guess that's how I'd set it up if that much tension was necessary.

View attachment 68373

Columnar loading on climber-tensioned speedline setup

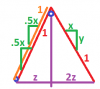

Consider the diagram below: speedline is brought from the anchor point (right side of below diagram), up to climber, through a pulley, then back down to an anchor opposite the terminal anchor but half the distance to the base of the tree as the speedline terminus (distance z vs. 2z), through a pulley at that position, and then back up to the climber. Orange colored rope in diagram would probably be a second rigging rope joined end-to-end with the speedline, necessary when progressing higher up the stem since 3 legs of rope are required - obviously, knot joining the two lines would have to be on the orange side of that second pulley (left).

The purpose is to reduce side-loading but also have the system be able to be advanced up the stem and tensioned by the climber.

Obviously, the angles/distances of the two lower anchors would be different than this 'ideal' diagram shows (z vs. 2z) since friction in the pulleys and sag/stretch in the speedline will bring the effective terminal anchor (right bottom) closer to the tree (distance 2z will be something less than 2z in reality once the weight of the piece is placed into it). However, is this idea sound? Namely, distance z is decreased to the anchor on the climber-tensioned side (orange/red, left bottom) since there are two legs, each ideally transmitting a force equal to the right side's single leg.

x and y are simply the horizontal and vertical components of the force vectors along each of those legs of line. I didn't go through the exercise of working out what the left side's legs' vertical component would be, since that's loading the stem in compression and I know it'll be greater than 1x and less than 3x the right side, and it also depends on the height at which that upper pulley is anchored at as well (meaning, it increases force at the highest point as the height increases up the stem).

View attachment 68374

It seems like you could incorporate either a cmi rope jack or RE aztec setup into a speedline system like this. I am not sure of the details of yours here, but I'm envisioning climbing to the top of the pine to set a omni 2.0 pulley, then installing speedline slings on the way back down to a hitch/rope jack or aztec pulley system, tightening it there, cutting, leaving the pulley and hitch in place, taking the rope jack up with you, jacking, cutting, etc. probably something that will illuminate itself while you're in tree, but have a backup plan.

I'm thinking about this more. I like your idea - I could anchor one redirect pulley at the top of the tree (I don't own an Omni, but I do own some Pintos...ok for this purpose, even with the small sheave? I'm using either Yale XTC Fire 16 strand or 1/2" true blue as my rigging line), and another redirect local to my work position with the speedline through it. Then, sling, tension the speedline, and cut all the local limbs.

The speedline redirect at the work position will hold the line with a consistent tension until I'm finished with the limbs local to that position.

Then, when done there, I move up to the next suitable place, reinstall the lower redirect, sling the limbs to cut, tension everything up, and let em fly. I'm wondering about bodyweight tensioning then just tying off to a stub, at the moment.

Does it sound like I'm following you, @colb?

I know I should calculate all this while at my desk, but I haven't, lol.

The main things to remember is that 1. the line will be under tension and thus immovable once the first limb is cut, 2. the line will be longer with each limb that is cut off, resulting in more sag that needs ma to overcome, and 3. the ma adjustment point needs to travel up the spar with you. #3 is the entry point for rigging innovation. I would lay your available kit out next to a sapling, start making mistakes, and take pics for the rest of us.

It's possible that you could tie a ropejack to a stub.

The load shouldn't be dumped into the rope jack, correct? I don't have one, but I was assuming that any tensioning device should be used to tension then removed from the system, versus leaving it in and potentially shock loading it.