Some ramblings.

The reeve line is basically a double whip so the line sees 1/2 chipper = 225 lbs. During lift pulley drag only adds .4x225 = 90 lbs more tension, lowers tension by 90 during lower. so its low stress

If you tension up the carry line reasonable, adding load is like sweating a tree-pull line sideways and a practical advantage is about 5x, so 450 lbs is going to at least 5x or 2500 lbs. If you redundant a second carry line it'll just add the pretension, net load will get divvied up to make 2500

the traverse line uphill is 450 lbs x sine hill/rope angle plus pulley drag so its a smaller portion of 450 lbs

to tighten or to catenary - if you trad highline tension tight the numbers get big. if you go easy on the tension the rope sags and forms a basket tending to roll the load to center span - then you're fighting uphill traverse load, but is it perhaps even lower than the pretension would be?

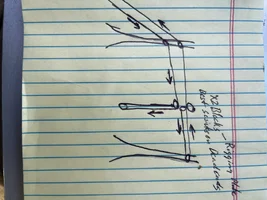

A possibility instead is backstay the two spars and do a 2 rope M rig, just increment the two lines to move the load. grcs at each tree base, line up to rigging pulley and down/attach to chipper/rigging plate/slings etc. however no support redundancy - that's a judgement call. net tension on the ropes might be even half sized depending on amount of sag

too much time on my hands

A little sidethought creeping in - if something fails and the chipper splats - not the same as brush or a log splatting. Occurred because of rescue guys examples being so redundant

The reeve line is basically a double whip so the line sees 1/2 chipper = 225 lbs. During lift pulley drag only adds .4x225 = 90 lbs more tension, lowers tension by 90 during lower. so its low stress

If you tension up the carry line reasonable, adding load is like sweating a tree-pull line sideways and a practical advantage is about 5x, so 450 lbs is going to at least 5x or 2500 lbs. If you redundant a second carry line it'll just add the pretension, net load will get divvied up to make 2500

the traverse line uphill is 450 lbs x sine hill/rope angle plus pulley drag so its a smaller portion of 450 lbs

to tighten or to catenary - if you trad highline tension tight the numbers get big. if you go easy on the tension the rope sags and forms a basket tending to roll the load to center span - then you're fighting uphill traverse load, but is it perhaps even lower than the pretension would be?

A possibility instead is backstay the two spars and do a 2 rope M rig, just increment the two lines to move the load. grcs at each tree base, line up to rigging pulley and down/attach to chipper/rigging plate/slings etc. however no support redundancy - that's a judgement call. net tension on the ropes might be even half sized depending on amount of sag

too much time on my hands

A little sidethought creeping in - if something fails and the chipper splats - not the same as brush or a log splatting. Occurred because of rescue guys examples being so redundant

Last edited: