Yes.. there's a gazillion different types including a lot of the same materials we use in cordage.. Technora, Nomex, Fire resistant, Fire Proof... Some of it can get very expensive as you go up in size (think space shuttles etc). But in reality, it's basically just a braided cover.. For this use though, all you need is a cheapo PET version.. that is unless you can find a material that slipperier.. did i just make that word up?

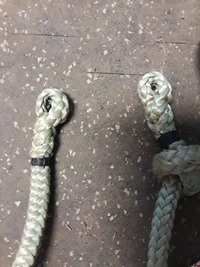

Haha.. Ironic.. i literally just finished up a couple Multi-Slings..

Question to those who push the splicing envelope -

Is it possible to get the flexibility out of a normal db splice somewhat similar to what you get out of a sewn eye..?

Do we have to pack as much cordage as we normally do into that bury in order to get legitimate break strengths? I think of this in terms of general cordage strength, whereas cordage will usually break wherever there is a deviation/disruption in it's size, right? If someone was to try & make the splice somewhat similar to the size of the cordage , would that be stronger or weaker than a jam packed swollen splice?

If i wanted to slim the splice down to make it more flexible & there is indeed a compromise with that, could i counteract that by measuring a longer fid length in the first measuring step to allow for a longer super tapered bury in the end? Could i do that without throwing all of the other measurements out of wack? My thought is to go full fid, maybe more, on the bury, but have it be super thin/tapered & flexible..

These are just my thoughts/qeustion.... I'd much rather just do everything normal & then go super slim in the tapers like some of my prespliced hitch cords seem to be.. However, other hitch cords i have are your normal swollen/hard splices, so if all things prespliced are supposed to be legit, deductive reasoning would say the slim/flexy tapers/splices are ok.. I just don't know what to think & haven't seen much talk about this particular topic..