Jehinten

Been here much more than a while

- Location

- Evansville

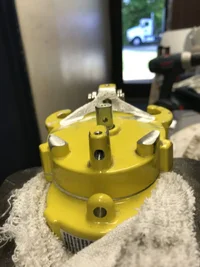

Thanks for the reply @Burrapeg. I guess I’ll start trimming away the obstacles and see if I can get the sheave off. Looks like there’s a set screw accessible from where the rope enters/exits that may have something to do with its removal. Then try to fab a fairlead on it. Yeah I definitely don’t plan to rely on this thing for life safety.

I believe I know which screw you are referring to. The only use of it on the R500 was to keep the infeed and outfeed of the rope from making contact and causing rope on rope friction. I had to remove mine in order to refeed my rope into the unit after removing it one time. My unit does not have the midline attachable modifications