Distance and Tension force here are reciprocals traded within a force volume of distance x tension.

Can imagine this trade inside a Zrig of 3xForce output (potential then less conversion tax); because force density concentrated into 1/3 distance. Can put full weight of milk jug concentrated to 1 spot, or dribble it out long, but same total volume to account for; no free rides. The dribble gives less dense weight power per inch, but more distance. Or imagine as a wide or narrow aquarium. Narrow gives more weight force per inch and more side glass force too. Get choice with same volume of water input to each. Denser weight at distance loss or more distance of less dense weight.

.

zrig has 3postions with 1,2,3 legs typically used as input, pivot, output respectively. But can have 3 as input, 2 pivot and 1 as output to gain distance/lose power. Like pulling 3x distance with output at 1/3 power like if short run for truck fishing load out of yard... Or can have 3 as pivot, 2 as input to only pull 2x as far at half input power. NOTE: 3x or 2x distance also means at 2x or 3x the speed of input. Safety considerations say keep low and slow, but then too, impact of such a hit if something happens is stronger per value against attaining dynamic state(mass) X value of of dynamic state (speed)SQUARED !!

.

Rigid Levers do same trade-off, nothing is free; in fact all has conversion tax.

Rigid Gears do the swap radially.

model: Ten-speed bike is fastest using large gear on front derailleur and yet smaller gear on rear derailleur !?!

because pedal as input arc distance into larger front gear gives more distance than further concentrating into denser force at distance los)s of smaller front gear.

BUT, reverse scenario from input arc to smaller output out vs. now chain delivers for smaller input arc to larger output arc(reverse of larger pedal arc to lesser arc front sprocket choices). For in the rear smaller input arc choices feeds into larger output arc of tire. So using smaller gear here dilutes the force, increasing the distance in trade as smaller gear goes to larger wheel as final output. Passing force volume mix to a larger rear gear would not then dilute out as much distance to final output to wheel. Would preserve more of the force, over the lesser distance (than passing force to smaller rear gear).

.

Rope is flexible Lever, but still handles the math-trade the same, nothing free.

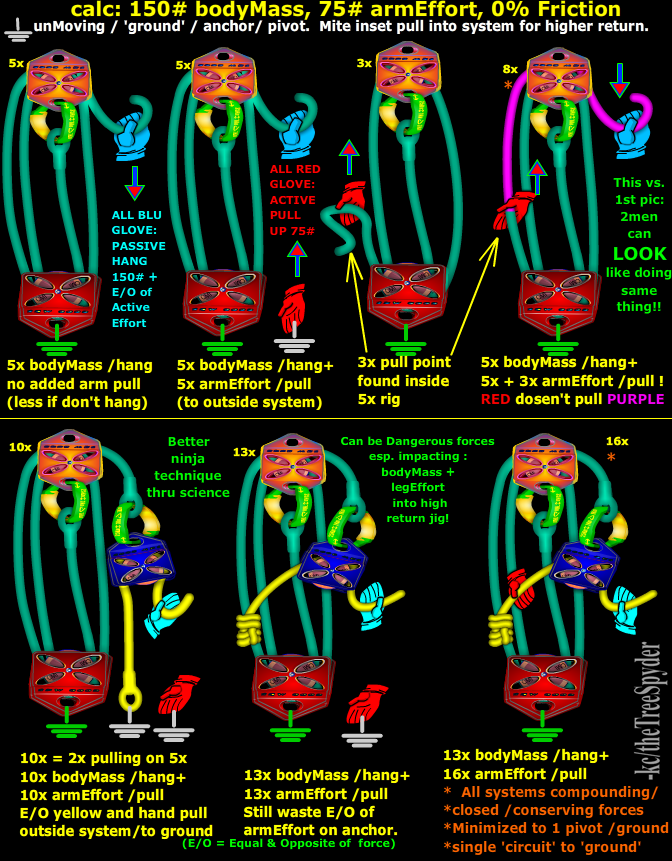

Numbers shown/spoken are potentials/finite limits to calc within. So assume impossibility of no friction AND also cosine of input at 100% aligned to work/other pulley legs. If slant input only get the co(lum)sine(as an efficiency)input into system to then multiply (less conversion taxes of friction).

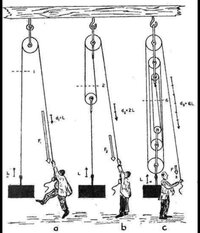

We can have compound levers at truck stop scale of a series of levers pushing each other to compound or dilute further. This can be done extensively inside transmission for rigid radial gears. But also in our "rolling levers" of flexible ropes. Meet the Burtons (2005 older style pic):

This can be an exercise to see, but once catch the form can trace it then more confidently into the simplers.

.

Sat so long in DdRT to realize it as a dumbwaiter 2/1-friction output, that then folded that dual input to 1 output inside of systems, and then how i recursively used systems inside of systems and how pulled on it.

Catch the nuance of how when hanging on end and locking to the interior grab too, as pull with arm as input to the interior, also make self heavier on the exterior pull to feed that too into system, at that input point's ratio to the final output. BUT then if locked interior arm pull and leg force as exterior input, will then also equal/opposite pass the leg force thru bod to fixed interior hand to input the leg force to that position ratio as well !!!!!!

A long time ago, Tom very aptly called a pull on open end as open system, and a DdRT dual pull as closed system to (differences. i think was at ISA 'BBS' Bulletin Board Service/s (pre Y2K bug when called these non-places forums); ty Tom, that has stuck with me well to help sift forensically and in predictions.

.

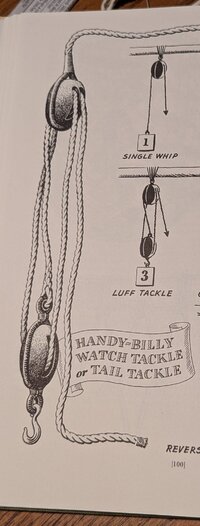

Marlinspike Sailor pics by Hervey Garret Smith are some of my all time faves from way back; that distilled and sifted much from also!