southsoundtree

Been here much more than a while

- Location

- Olympia, WA

How many degrees off the lean to have a clear layout and safety cushion?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thanks for the input. The soil here is over compacted (from the last glacier) clay. If the anchor fails it would be from breaking the half-inch steel and not from the soil letting loose.We are in very sandy soil here and I’d require something more to give me more faith! I’ve never tried to guy for felling purposes only utilizing for tree repair and straightening, so I don’t know if you calculate the weight of the tree vs the holding power of that anchor ?? Maybe add a few for back up if you can’t get somthing heavy in that area or a tree to use is usually my luck! It’s looks pretty open is why I asked to begin with. As others have added and that was next question what are we trying to avoid beyond that lean we can’t see!?

Good planHire someone to blow the top out of it and leave....no cleanup, not felling the trunk. That won't take very long so won't be too expensive and could very well save a life and garage.

There’s always a good excuse to buy more rope! I’m on the side of advocating for getting a climber. Looks like an easy tree to make salad from. Have them save you the spar and once cleanup is done play round with taking the spar over backwards. Much more predictable.Thanks for the input. The soil here is over compacted (from the last glacier) clay. If the anchor fails it would be from breaking the half-inch steel and not from the soil letting loose.

If the tree drops in the direction of lean it will trash several decent spruce trees and a white pine, and also trash a nicely built raised bed garden area. My height estimate of the tree I did today makes it look like it won't hit the garage. If I can get it to fall even 45 degrees from the lean it will save the trees. 90 degrees saves the garden structure.

I'm going to look at alternatives to the soil anchor. There may be some large trees I could use. Probably farther away than I my 5/8" line will reach, but safer than using the soil anchor (and less work). I have plenty of 1/2" rigging line I can use.

Thanks for all the suggestions and words of caution (and tree ID).

Thanks for putting it in ‘layman’s’ termsMusings on resulting lays.

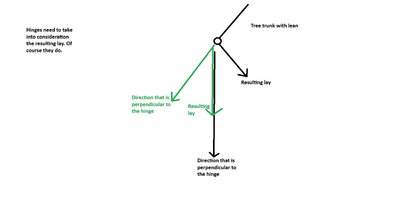

All of this geometry plays very much into the needed angle of the guying line, or lines. The guy line support operates in an arc with the anchor point location determining the shape of this arc. The trunk and hinge act as a straight line being supported by a guy line offering 'support' that changes along this arc.

Is the anchor point perpendicular to the lean? Or perpendicular to the hinge?

Almost all arborist and fellers use intuition.

But it is all quite complicated.

View attachment 96429

I did a guy line on a good size lead off an oak some <~> ten years ago with some 1/2 inch diameter line (first mistake ) and we did not use a portawrap ( mistake 2) to adjust the slack during the fall just took wraps and tied off on a tree as perpendicular as I could get on the situation. It was no perfect setup by any means . The line held , but the cover was popped off on the core of the rope after the dust settled! Acually thinking back on it mistake one was not dismantling it to take some weight off and going for it late in the day after a lot of other work already transpired!Whether it’s a Boxelder or an ash, I’d be most concerned about hinge tear out. If you do plan on felling it whole, I’d make sure to counteract the lean with the estimated force necessary on a tag line. I would probably transfer the tensioned tag line onto a portawrap, so that someone could give it slack if it was swinging too far past the desired lay. Leaving a thick hinge on the opposite side of the lean. Ratchet strap around the trunk above the cut to prevent barberchairing. Open face notch. And of course a separate tag line in the direction of the lay.

Thanks for putting it in ‘layman’s’ terms

did this with a 3 strand line as the guy line. Rope was tighter than a banjo string when the tree hit the ground. If the rope would have snapped, could have recoiled in a number of people. That's when I learned about the Arc path and the need to play out line at an appropriate pace as the tree falls. Wasn't even a big tree, just wanted to mitigate the potential of the hinge breaking as the tree was leaning hard towards a road.I did a guy line on a good size lead off an oak some <~> ten years ago with some 1/2 inch diameter line (first mistake ) and we did not use a portawrap ( mistake 2) to adjust the slack during the fall just took wraps and tied off on a tree as perpendicular as I could get on the situation. It was no perfect setup by any means . The line held , but the cover was popped off on the core of the rope after the dust settled! Acually thinking back on it mistake one was not dismantling it to take some weight off and going for it late in the day after a lot of other work already transpired!

I gotta love a good lesson learned where it all turns out not bad or , better yet a cheaper lesson from others mistakes on a forum far away from the job site, hence why I’ve no issue sharing my own!did this with a 3 strand line as the guy line. Rope was tighter than a banjo string when the tree hit the ground. If the rope would have snapped, could have recoiled in a number of people. That's when I learned about the Arc path and the need to play out line at an appropriate pace as the tree falls. Wasn't even a big tree, just wanted to mitigate the potential of the hinge breaking as the tree was leaning hard towards a road.

Yup always best to have it through a porty or oldschool trunk wraps. Takes a second person but a little adjustment goes along ways.did this with a 3 strand line as the guy line. Rope was tighter than a banjo string when the tree hit the ground. If the rope would have snapped, could have recoiled in a number of people. That's when I learned about the Arc path and the need to play out line at an appropriate pace as the tree falls. Wasn't even a big tree, just wanted to mitigate the potential of the hinge breaking as the tree was leaning hard towards a road.

I don't.. box elder is one of the worst hinging woods I have ever had to cut.Not that it matters too much in terms of the plan, but I personally trust Boxelder to hinge better than Norway. It is softer but more flexible.

Sure that can be effective or choice. But reading the OP, I wouldn’t advise adding a 3rd new practice element to the equation.pretty simple.. you can do it!