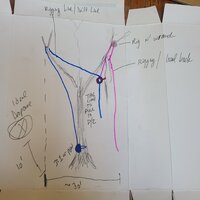

I think that this will be my plan.

Both ropes are full size rigging lines.

The blue line will be a rigging line or drift line. Mid-line ttaching blue to a steel rigging ring (or rigging plate) will allow the blue line to also be a tag line.

I'll likely set a Port-a-wrap with a 3:1 at the base. I can use the POW as a redirection point for a horizontal MA system, keeping everthing in easy reach, unless I want to pretension the blue line.

The pink will be as a rigging line, hold-back line or haul-back line, likely through a Rig'n'Wrench.

I'll use a sling and biner to connect each tree-part to the rigging ring. Unclipping the sling that is hitched to the branch from the carabiner will free the system, allowing me to pull the rigging ring back to me asap for setting the next piece, which I'll have already slung, waiting to clip and go.

Burning brush as we go will help production and be warm.

View attachment 96560