Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Documenting my hand-sewn eye process

- Thread starter moss

- Start date

bonner1040

Branched out member

- Location

- Boston

No, it shouldnt be done because there is no reason.

good point, factory stitched- $20No, it shouldnt be done because there is no reason.

SoftBankHawks

Branched out member

- Location

- Japan

Crikey, what an awful thing to say and without any detail of context.Someone is going to die because of this Andrew. Probably not you, but someone.

Quality control is difficult. I recently commissioned a set of machine stitched eyes from a well known arborist supplier and was shocked to see melted rope beneath the shrink tube. Empowerment is just that Nick, please remember that we do not all have access to machines and test beds and must do what we can, professionally and with high craft standards.

Nobody will die because of this Nick, maybe you, but no-one.

bonner1040

Branched out member

- Location

- Boston

I respectfully disagree

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

SoftBankHawks

Branched out member

- Location

- Japan

...about what?

Worthaug

Carpal tunnel level member

- Location

- North Cakilaki

Prolly about anything you said...about what?

Reed Wortley

CTSP #01739

ISA CA #SO-6953A

And that's exactly why this shouldn't be done.we do not all have access to machines and test beds

A hand splice has definitive instructions that say if you follow these to the letter and everything looks OK when you're done the splice will meet safety standards. A guy on an internet message board with a modified sewing needle, some hardware store clamps, and electrical tape can't make that same claim.

If you want to make some accessory stuff to play around with, that's one thing, but I wouldn't risk anyone's life to hand sewn eyes. We're talking about $15 here. Treestuff will add a sewn eye to any rope for $15 and their sewn eye to eyes are about $15-$20 more than the cost of the material. It's not much money for a lot of peace of mind.

Hand sewn eyes is as much a bad idea as climbing on rope and carabiners from the hardware store. And we don't do that do we?

bonner1040

Branched out member

- Location

- Boston

^^^ Finally some sense here.

bonner1040

Branched out member

- Location

- Boston

I have hand sewn lots of saw lanyards, foot loops, etc.

I am a huge proponent of DIY projects from splicing, to APTAs, to Arbor Trolleys.

Plenty of people here know me personally, so feel free to ask around (aka don't take my word for it), I am not trying to make y'all buy more stitches, just trying to prevent someone from making a fatal error.

I am a huge proponent of DIY projects from splicing, to APTAs, to Arbor Trolleys.

Plenty of people here know me personally, so feel free to ask around (aka don't take my word for it), I am not trying to make y'all buy more stitches, just trying to prevent someone from making a fatal error.

JeffGu

Been here much more than a while

- Location

- Osceola, Nebraska

No, it shouldnt be done because there is no reason.

Personally, I believe that with several thousand years of humans hand-stitching all manner of things, that you can most likely do the same for spliced eyes. I think it would make sense to practice on a cheap rigging line like Forestry Pro and get them pull tested. Nick should probably volunteer to break test a dozen, in the interests of preventing future deaths. With good attention to detail and consistency, I suspect this could be done safely, but I'm speculating.

As for there being no reason to do it... well, try to get the usual suspects to machine stitch eyes in used rope or Bag-O-Rope hanks. Seems like most places will only splice rope that you buy from them. Usually, liability is the reason given, but a release from liability form solves that problem, so I'm skeptical.

Of course, I'm playing devil's advocate to some degree. But, I'd want to see hand-stitched eyes failing a pull test all over the place before I claimed that death was imminent. I strongly suspect that they'll break at over 70% of rope strength, which means they're no more dangerous than tying a knot in the rope. Would be nice to see some break test results.

bonner1040

Branched out member

- Location

- Boston

Totally untrue. I will stitch any suitable rope you send in, used or not.

I wont break test any more hand sewn eyes (volunteer, paid, or otherwise) because the data is useless and only serves to encourage people. The process is unrepeatable. A CNC stitch pattern precisely places stitches within tenths of a millimeter, thousands of an inch. Can you do that by hand? I am happy to refer a Chant/Mitsubishi/High-Tex salesperson though.

Sure they might break high, do they last? How do they hold up to thousands of cycles?

Release from liability forms? That isn't a serious thing is it? I would have to have my lawyer write that, which costs a fortune and still wouldn't protect anyone. But its not relevant because (again) I will stitch any suitable rope you send in, used or not.

The key word in all of that Jeff is speculating. Speculate with the stock market or real estate, not hand stitching life support rope with a speedy stitcher.

I wont break test any more hand sewn eyes (volunteer, paid, or otherwise) because the data is useless and only serves to encourage people. The process is unrepeatable. A CNC stitch pattern precisely places stitches within tenths of a millimeter, thousands of an inch. Can you do that by hand? I am happy to refer a Chant/Mitsubishi/High-Tex salesperson though.

Sure they might break high, do they last? How do they hold up to thousands of cycles?

Release from liability forms? That isn't a serious thing is it? I would have to have my lawyer write that, which costs a fortune and still wouldn't protect anyone. But its not relevant because (again) I will stitch any suitable rope you send in, used or not.

The key word in all of that Jeff is speculating. Speculate with the stock market or real estate, not hand stitching life support rope with a speedy stitcher.

JeffGu

Been here much more than a while

- Location

- Osceola, Nebraska

...key word in all of that Jeff is speculating...

Well, you make some good points, Nick... repeatable quality might be an issue. Still, try it on a rigging rope and start dropping logs on it and I would think the rest could be sorted out in short order.

I will stitch any suitable rope you send in...

I was unaware that TreeStuff would stitch eyes in rope that was sent in. Nobody else I contacted a year or two back would do it, but that was probably before I discovered TreeStuff. Glad to hear I can get it done there.

Of course, I'm playing devil's advocate...

I don't actually think you should break test them... like you said, it might encourage people to try it that have no patience or attention to detail. It would also tend to give the appearance of condoning the process, which you clearly don't.

Still, I think it's an idea worth pursuing. But, in truth, I think it would be a whole lot better left to rigging/accessory stuff than a climbing rope.

Last edited:

fall_risk

Participating member

- Location

- Philadelphia

Well, if nothing else, I am also really glad to know about this option. I am starting to prefer stitched terminations, and I'm pretty sure that ARS, Fanno, Silky, and Samurai are in cahoots with the rope companies to put saw magnets in double braids.I will stitch any suitable rope you send in, used or not.

Sent from my XT1080 using Tapatalk

Treezybreez

Been here much more than a while

- Location

- Lancaster, SC

A poor quality eye splice from a reputable Tree supply company is what got me into hand splicing. Well, that and a bran new rigging line that was accidentally nicked in the middle.Crikey, what an awful thing to say and without any detail of context.

Quality control is difficult. I recently commissioned a set of machine stitched eyes from a well known arborist supplier and was shocked to see melted rope beneath the shrink tube. Empowerment is just that Nick, please remember that we do not all have access to machines and test beds and must do what we can, professionally and with high craft standards.

Nobody will die because of this Nick, maybe you, but no-one.

I personally would not hand stitch my own eye and eyes because of the amount of time it would take. Plus the bloody fingers I am sure would happen. Why stitch em when splicing is more streamline?

- Location

- Copenhagen

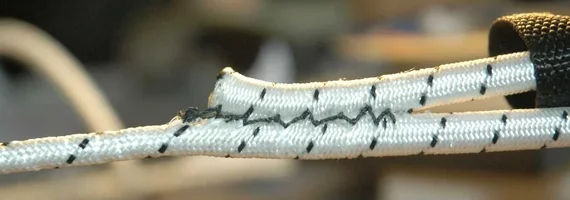

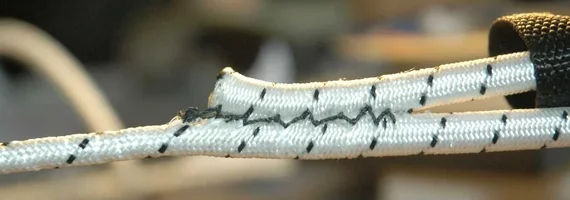

I have a non-safety application using shock cord. For this I have made some experiments on different kinds of eye terminations of shock cord, and one of them is a sewn eye. In this photo you see the eye with the Ø10 mm shock cord pulled to a length of 220% of its unstressed length.

Notice, that it is the first part of the stiches, that takes most of the load due to the different elongation of the shock cord on each side.

Dynamic ropes a peak load during a fall would normally be pulled to about 130% of unstressed length, so you can expect something like this to happen on this kind of rope as well.

Notice, that it is the first part of the stiches, that takes most of the load due to the different elongation of the shock cord on each side.

Dynamic ropes a peak load during a fall would normally be pulled to about 130% of unstressed length, so you can expect something like this to happen on this kind of rope as well.

Richard Mumford-yoyoman

Been here a while

- Location

- Atlanta GA

TreeStuff is awesome.Totally untrue. I will stitch any suitable rope you send in, used or not.

Saying that someone will die is a little harsh, we go through that line of thinking every time we put out a new idea. I certainly understand the concerns and if it causes people to step back a little, that's probably a good thing. Moss is extremely capable, with exemplary craftsmanship and I appreciate him sharing what he learns and knows. I have to take extreme caution to think that I can duplicate what he does.

I find it unfair. You say you like diy projects. I really enjoy stitching rope and ive followed moss's instructions to the letter. But to say were going to die except moss makes it seem like you think were to stupid to do this. I dont mean to be rude but youve put a bad taste in my mouth about a good company

New threads New posts

-

test

-

-

-

-

-

Free CEUs: Mar 05 & April 09 - 'Urban Forestry Today’ Webcasts @ Noon (Eastern)

- Started by UFT

- Replies: 0

-