The break test that I describe above only tells me that I can Sew i2i's, I don't plan on using a revolver or any other biner in the loop because I haven't had it tested. A carbiner used would only load one of the cords because of the design of my loop. Hence the dyneema loop with two wrap girth hitch....I got the idea for the loop in the prusick from tufelberger, they have something with a similar loop on Honeybros website, (ring loop)

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Documenting my hand-sewn eye process

- Thread starter moss

- Start date

moss

Been here much more than a while

- Location

- Carlisle, Massachusetts, U.S.

[ QUOTE ]

Sorry it took so long to get back..

As for technique, I don't do any precompression, on the rope.(not that that isn't a great idea.) When I sew, I start with the inner chevrons that are touching, and am careful not to over tighten, I sew the full length of the splice, when I come to the end, I jump to the next set of chevrons and change directions, I sew straight across,(no X's) It is similar to welding two pieces of metal,(filling the gap) I can't take any credit for this, I got the idea after dissecting retired split tails purchased from reputable dealers. As far as tightness of stitching, I have found that by the time I reach top dead center of both sides It's rock hard and there is a point where it won't take one more stitch..... My break test cordage was 10mm Sirius Reep. Hand stitched in the fashion described above, two tight eyes, Basket pull,failed at 11,560 lbs cordage broke at the bottom of the basket , inspection of splices after test showed little distortion.

I'll get a couple more pics up soon Tom...

[/ QUOTE ]

Sorry Hitman, I missed your posts in this thread, super awesome! Great great work, truly artistic, and practical! I know how much work goes into this, congrats on the excellent results.

-AJ

Sorry it took so long to get back..

As for technique, I don't do any precompression, on the rope.(not that that isn't a great idea.) When I sew, I start with the inner chevrons that are touching, and am careful not to over tighten, I sew the full length of the splice, when I come to the end, I jump to the next set of chevrons and change directions, I sew straight across,(no X's) It is similar to welding two pieces of metal,(filling the gap) I can't take any credit for this, I got the idea after dissecting retired split tails purchased from reputable dealers. As far as tightness of stitching, I have found that by the time I reach top dead center of both sides It's rock hard and there is a point where it won't take one more stitch..... My break test cordage was 10mm Sirius Reep. Hand stitched in the fashion described above, two tight eyes, Basket pull,failed at 11,560 lbs cordage broke at the bottom of the basket , inspection of splices after test showed little distortion.

I'll get a couple more pics up soon Tom...

[/ QUOTE ]

Sorry Hitman, I missed your posts in this thread, super awesome! Great great work, truly artistic, and practical! I know how much work goes into this, congrats on the excellent results.

-AJ

- Location

- Phoenix

I know this is an old thread but it inspired me to start putting a sewn splice instead of paying for traditional slice. Its things like this that separate our profession from most others. thanks for the insight guys

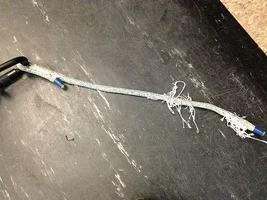

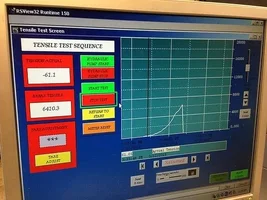

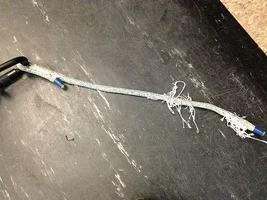

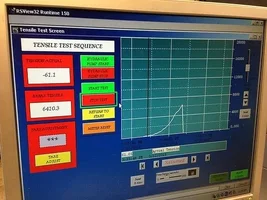

I made a couple sewn eyes in a short piece of 9mm epiCORD and did a straight pull, eye to eye (not the way it looks with both eyes on the biner, more so how it looks in the second photo). It broke at just over 6,400 lbs. I'd guess it would be about 2x that in basket? Anyway, glad to know my results.

Last edited:

TreeLogic

Branched out member

- Location

- Coastal SC

Good stuff Eric. Did you use Moss' method to hand stitch those eyes?

MikePowers321

Carpal tunnel level member

- Location

- Leeds, Ny

So I want to learn to stitch rope properly. What I have in mind is not for life support but stitching a kind of bridge on the back of my saddle for my chainsaw lanyard as I tend to use both sides when cutting. That way I have extra reach to either side. I alternate quite a bit.

Can anyone point me in the right direction in terms of proper technique? Is this stuff the way to go?

http://www.treestuff.com/store/catalog.asp?item=14662

I mean I could have ass it and I'm sure everything would hold but I know you guys have some ideal tips....

Can anyone point me in the right direction in terms of proper technique? Is this stuff the way to go?

http://www.treestuff.com/store/catalog.asp?item=14662

I mean I could have ass it and I'm sure everything would hold but I know you guys have some ideal tips....

I think the method is similar.Good stuff Eric. Did you use Moss' method to hand stitch those eyes?

Pass 1 is about 22.5 degree off angle on each side, and done where it would catch only the cover strands.

Pass 2 is done just outside of pass 1 and only about 5 degree deviation.

Pass 3 takes the longest, and gets real tight and stiff at close to 0 degrees.

The entire stitch takes just under 10 feet of thread, and yes, it was #4 Marlow.

One of the most important things is having the right needle. You don't want a chisel needle since that will cut hitch cord fibers, especially in the last pass.

Last edited:

Worthaug

Carpal tunnel level member

- Location

- North Cakilaki

Mike this is a great idea!So I want to learn to stitch rope properly. What I have in mind is not for life support but stitching a kind of bridge on the back of my saddle for my chainsaw lanyard as I tend to use both sides when cutting. That way I have extra reach to either side. I alternate quite a bit.

Can anyone point me in the right direction in terms of proper technique? Is this stuff the way to go?

http://www.treestuff.com/store/catalog.asp?item=14662

I mean I could have ass it and I'm sure everything would hold but I know you guys have some ideal tips....

This may sound like more work but I would suggest 3/8" tenex (which is really easy to splice with a basket fid) and a corduroy sleeve stitched to it. Different approach but it would teach you to splice hollow braid...

MikePowers321

Carpal tunnel level member

- Location

- Leeds, Ny

I know that splicing tenex is supposed to be easy, yet I still have no splicing skills.

There is an area on my treemotion that I can just squeeze in some 6mm op in between the webbing and the saddle itself. I already have it done. I just want to redo it properly so that if I drop a slightly bigger saw (like 346 or 550) it won't tear out on me.

But yeah, it is a good idea : )

There is an area on my treemotion that I can just squeeze in some 6mm op in between the webbing and the saddle itself. I already have it done. I just want to redo it properly so that if I drop a slightly bigger saw (like 346 or 550) it won't tear out on me.

But yeah, it is a good idea : )

Last edited:

...Can anyone point me in the right direction in terms of proper technique? Is this stuff the way to go?

http://www.treestuff.com/store/catalog.asp?item=14662...

Disclaimer...I have just started hand stitching rope but have done a fair amount of machine sewing webbing and a very limited amount of machine stitching small diameter accessory cord and shock cord.

The #4 whipping twine from Marlow is a waxed polyester twine and should do a good job for a chainsaw bridge.

I just did a quick and dirty 'break test' on Marlow #4 whipping twine and it broke at ~39 lbs.

Figure out the strength you want and using 39 lbs per stitch to calculate the minimum number of stitches required, should leave you well on the safe side as it does not include the additional strength gained from friction within the stitched splice. More is better.

See the beginning of this thread for a good method of hand stitching splices.

Expect both ends of the bridge to see the full weight of the chainsaw and any shock loading.

Pull the core out of some 8mm cordage and use that. It's easy to fold over and make a small bar tack by hand.I know that splicing tenex is supposed to be easy, yet I still have no splicing skills.

There is an area on my treemotion that I can just squeeze in some 6mm op in between the webbing and the saddle itself. I already have it done. I just want to redo it properly so that if I drop a slightly bigger saw (like 346 or 550) it won't tear out on me.

But yeah, it is a good idea : )

evo

Been here much more than a while

- Location

- My Island, WA

I did this with some scrap ICE Tail that was too short for a hitch, just a locking brumels an tuck the tail (no real bury)So I want to learn to stitch rope properly. What I have in mind is not for life support but stitching a kind of bridge on the back of my saddle for my chainsaw lanyard as I tend to use both sides when cutting. That way I have extra reach to either side. I alternate quite a bit.

Can anyone point me in the right direction in terms of proper technique? Is this stuff the way to go?

http://www.treestuff.com/store/catalog.asp?item=14662

I mean I could have ass it and I'm sure everything would hold but I know you guys have some ideal tips....

I 'accidently' stitched up a thimble loop today. When I started, I was just curious how well the Bee Line would fit the thimble I had and after my earlier "break testing" of the Marlow #4 twine, if it would fit the speedy stitcher needles I had. It all fit so I figured I would round off and polish the needle's chisel edges and make a few stitches to see how it went and brush up on using the SS. It was all working so I kept stitching...not thinking about how I would like the end stubs to be permanently whipped or taped and not thinking to put a piece of shrink tube on. After the stitching was done, I ended up whipping the frayed ends to the loop and 'painted' the splice with MaxiJacket to give it a little protection.

It ain't pretty, but for the application, with 110 stitches, the strength should be there. I made four passes with each pass being wider and at a lower angle. I definitely have to work of uniformity on stitching. For an accidental first effort, I'm happy.

Is everyone using the standard lock stitch as shown in the speedy stitcher instructions or is anyone using a hand stitching needle and passing it down through one side, up through the other and round and round?

It ain't pretty, but for the application, with 110 stitches, the strength should be there. I made four passes with each pass being wider and at a lower angle. I definitely have to work of uniformity on stitching. For an accidental first effort, I'm happy.

Is everyone using the standard lock stitch as shown in the speedy stitcher instructions or is anyone using a hand stitching needle and passing it down through one side, up through the other and round and round?

I did a few continuous wrap stitches on a non-life support cord, but never tested it. I would use the lock method that comes with the Speedy unit. That's what I did with my hitch that was break-tested. Seems to be the way IMO.I 'accidently' stitched up a thimble loop today. When I started, I was just curious how well the Bee Line would fit the thimble I had and after my earlier "break testing" of the Marlow #4 twine, if it would fit the speedy stitcher needles I had. It all fit so I figured I would round off and polish the needle's chisel edges and make a few stitches to see how it went and brush up on using the SS. It was all working so I kept stitching...not thinking about how I would like the end stubs to be permanently whipped or taped and not thinking to put a piece of shrink tube on. After the stitching was done, I ended up whipping the frayed ends to the loop and 'painted' the splice with MaxiJacket to give it a little protection.

It ain't pretty, but for the application, with 110 stitches, the strength should be there. I made four passes with each pass being wider and at a lower angle. I definitely have to work of uniformity on stitching. For an accidental first effort, I'm happy.

Is everyone using the standard lock stitch as shown in the speedy stitcher instructions or is anyone using a hand stitching needle and passing it down through one side, up through the other and round and round?

View attachment 30933

Last edited:

The sewn pattern looks good and even, though perhaps thin for a parallel strand core.Last night's project with NE Fly. Time to head to the trees for some non-destructive testing.

View attachment 31106

Edit: test climb done, I'm alive and all's well.

How many passes did you run, and at what angles? Lock stitches or continual direction?

Will you be having this pulled to failure with documentation?

I stayed close to your recommendations widening each pass...

All lock stitching.

Pass 1 - 43 stitches with Marlow # four whipping twine which breaks at 39 lbs of pull in my testing.

Pass 2 - 48 stitches with size 415 waxed polyester thread. It's rated at 73 lbs and in my break testing, it failed at 50 lbs but always at a knot. 50 is ~68% of 73 which is about the derating to be expected due to a knot.

Pass 3 - 55 stitches with size 415 waxed thread.

Calculated strength in the stitching only, conservatively using strengths of 35 lbs for the #4 twine, 50 lbs for the 415 thread is 6655 lbs. Don't get me wrong, I'm not saying that I believe the eye would break test that high, just that there is some degree of comfort to me to have made that sort of calculation.

The final pass stitch width is ~10mm and I agree it would be better to be wider on the parallel strand core. It looks a little narrower in the photo due to the way the entry points are pulled inward as each stitch is tightened.

The length of the stitched area is 2.5" compared to the 2" in all of my ropes done by ABR.

I do not expect to have it pulled to destruction.

There is a Bulldog Bone on Yale Aztec hidden behind the Zigzag which I am also clipped into.

...Pass 1 is about 22.5 degree off angle on each side, and done where it would catch only the cover strands.

Pass 2 is done just outside of pass 1 and only about 5 degree deviation.

Pass 3 takes the longest, and gets real tight and stiff at close to 0 degrees....

All lock stitching.

Pass 1 - 43 stitches with Marlow # four whipping twine which breaks at 39 lbs of pull in my testing.

Pass 2 - 48 stitches with size 415 waxed polyester thread. It's rated at 73 lbs and in my break testing, it failed at 50 lbs but always at a knot. 50 is ~68% of 73 which is about the derating to be expected due to a knot.

Pass 3 - 55 stitches with size 415 waxed thread.

Calculated strength in the stitching only, conservatively using strengths of 35 lbs for the #4 twine, 50 lbs for the 415 thread is 6655 lbs. Don't get me wrong, I'm not saying that I believe the eye would break test that high, just that there is some degree of comfort to me to have made that sort of calculation.

The final pass stitch width is ~10mm and I agree it would be better to be wider on the parallel strand core. It looks a little narrower in the photo due to the way the entry points are pulled inward as each stitch is tightened.

The length of the stitched area is 2.5" compared to the 2" in all of my ropes done by ABR.

I do not expect to have it pulled to destruction.

There is a Bulldog Bone on Yale Aztec hidden behind the Zigzag which I am also clipped into.

been following this thread for awhile and im thinkning about trying this out for size. can you explain the whole angle thing?? and the lock sitches or continual direction? i plan on using my speedy stitcher so it would be lock sitches right??

thanks!

thanks!

Yes, if you follow the speedy stitcher directions, it will make a lock stitch.

The needles that come with the SS are a chisel point for leather and are made to cut the leather. The potential for cutting rope fibers makes them a poor choice for sewing ropes. In the very least, the SS needles need to have the sharp chisel edges well rounded off and polished. This can be done with knife sharpening stones, etc.

I'll let oceans discuss angles and stitch patterns.

The needles that come with the SS are a chisel point for leather and are made to cut the leather. The potential for cutting rope fibers makes them a poor choice for sewing ropes. In the very least, the SS needles need to have the sharp chisel edges well rounded off and polished. This can be done with knife sharpening stones, etc.

I'll let oceans discuss angles and stitch patterns.

yeah I'm really familiar with my SS, ive made belts, bags, chest harnesses, neck tethers, chainsaw lanyards, dog toys, etc!

New threads New posts

-

test

-

-

-

-

-

Free CEUs: Mar 05 & April 09 - 'Urban Forestry Today’ Webcasts @ Noon (Eastern)

- Started by UFT

- Replies: 0

-