Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

I prefer my truck on my truck... If I pulled out the 3:1 MA Z rig my guys would ;look at me like I was crazy.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

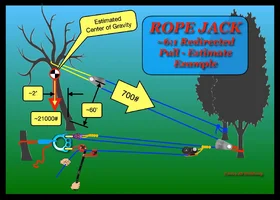

Example of one Pull-line force estimation method: estimated weight of tree 21,000#, horizontal distance from estimated center of gravity to hinge 2', estimated perpendicular distance from pull-line to hinge 60'.

The tree rigged in this manner is similar to a lever at approximately 30:1 (60/2) moving the 21000# with 700# pull. A Rope Jack through a 6:1 Mechanical Advantage is capable of approximately 3000# pull. So, the pull in this example was deemed adequately safe and well within the capacity of the rigging lines and the Rope Jack.

So far, over the years, this has proven to be the simplest RJ/MA "max-pull" kit to ease a heavy-back-leaner to the 'lay'. DWT x Z-rig = 6:1 (redirected)

This is my preferred pull for a heavy back leaner or for pulling a tree though a thick canopy. Rope Jack x 6:1 (redirected) = 30:1. So, 100 pound pull on the Rope Jack yields ~3000 pounds pull on the bare tree, on the left.

I use variations of this for pulling over heavy back-leaners. The 3:1, or the 2:1, or both are eliminated if not necessary for lighter loads.

Note: I make the yellow sling, in the diagram. It is a long hank of rigging line tied with a Zeppelin Bend and is long enough so the hardware is usually out of the way when the tree hits.

I use to use a base tie. But, half the time the tree would roll onto the rope and bury it deep under heavy wood. The yellow "long-sling" is long enough, so, even if the tree rolls, it usually does not seriously trap the rope since it's at the lighter-end of the tree.

Another advantage of a long-sling is it can include several branches to good effect. This is especially useful in a thick conifer. Simply throw the line high around both sides and tie the ZB on the far-side; install the block & pull. View attachment 62391

Great illustration!

What is the relationship between the 21000lbs. downward force of the tree, 2 ft. horizontal between cog and base, and 700 lbs. applied MA? How do you know how much ma you will need and how much force the tree is putting out on the opposite vector?

It's fairly simple mechanics. The perpendicular distance from the "gravity-vector" of 21,000 lbs to the pivot-point (hinge) is 2'. That can be expressed as a counter-clockwise moment of -42,000 lb-ft . That is balanced with a "pull-vector" of 700 lbs at perpendicular distance of 60' to the same pivot-point. That is a clockwise moment of +42,000 lb-ft. So, anything over 700 lbs on the pull-line will 'ease' the tree to the intended lay.

Where did you learn that? Is this a Beranek thing?

University of Maryland, College of Mechanical Engineering

Or twoWhile I've used come alongs and masdams many times in the past, I don't own either and neither does my current employer.

We each use our 5:1 setups fairly often, and there really aren't any times I would prefer having a come along. Haven't found anything I can't do yet with a 5:1!