flyingsquirrel25

Carpal tunnel level member

- Location

- South East, PA

[ QUOTE ]

[ QUOTE ]

What ever happened to hand wrapping a short span with common grade cable? I have not tried the Rigguy system and dont really want to. The whole reason we replace cables that are grown over is to prevent that bending action on the cable. The rigguy system starts off with this problem. I like through bolts, thimbols, dead ends and cable.

I have not tried the Rigguy system and dont really want to. The whole reason we replace cables that are grown over is to prevent that bending action on the cable. The rigguy system starts off with this problem. I like through bolts, thimbols, dead ends and cable.

[/ QUOTE ]

Typically, short spans such as crotches with included bark are more a candidate for a static cabling system with EHS wire rope in which case you cannot hand wrap (splice)such as you can with common grade.

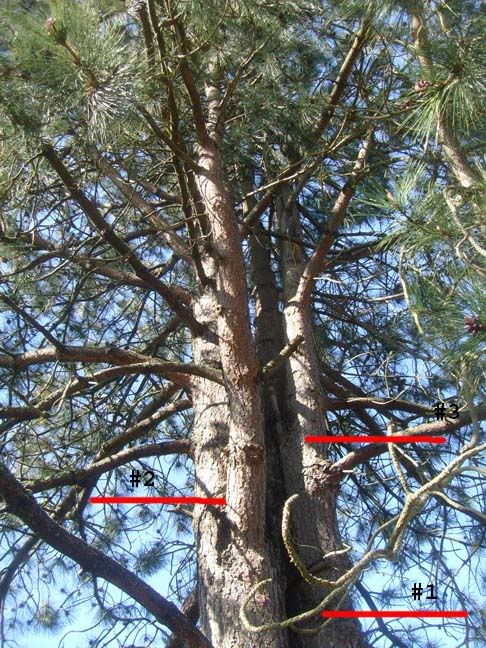

You could rod the lower stem and use a static cabling system 2/3rds up from the codom.

[/ QUOTE ]

BMPs, are suggesting that you can use Common grade cable on co-doms with attachment points up to 20" Diameter, with 1/2" cable and hardware. It doesnt say anything that I can find about included bark crotches requiring EHS cable. What it does say is if there is decay, split or other defect (ie included bark) the addition of a bracing rod should be considered.

[ QUOTE ]

What ever happened to hand wrapping a short span with common grade cable?

[/ QUOTE ]

Typically, short spans such as crotches with included bark are more a candidate for a static cabling system with EHS wire rope in which case you cannot hand wrap (splice)such as you can with common grade.

You could rod the lower stem and use a static cabling system 2/3rds up from the codom.

[/ QUOTE ]

BMPs, are suggesting that you can use Common grade cable on co-doms with attachment points up to 20" Diameter, with 1/2" cable and hardware. It doesnt say anything that I can find about included bark crotches requiring EHS cable. What it does say is if there is decay, split or other defect (ie included bark) the addition of a bracing rod should be considered.