Dan Thornton

Participating member

- Location

- Smithsburg

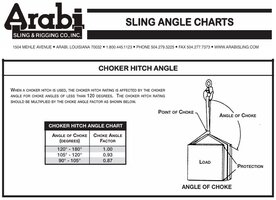

If the block is tied tight to the tree stem the forces get large quickly. And don't we all want to tie it as tightly as possible???Feels a bit nuts to say that a sling rated for almost 25K lb is undersized, but with heavy, terminal rigging, once you get into shock loading and such dynamics, it really is.

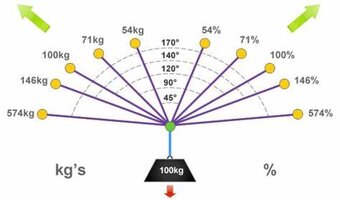

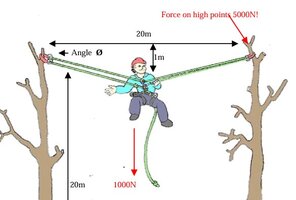

In setting up a hammock, some people try to tie the hammock straps as tightly as possible to the trees. This is a huge mistake. Ideal is having the hammock straps on a 30-degree rise from hammock to tree. At that angle a 200-pound body puts 200 pounds of strain on each strap. If I tighten it up so the rise on each end is only 15 degrees the strain on each strap is 386 pounds, almost double the downward force.

If, God forbid, I tighten it to only 5 degrees of rise on each strap, then each strap is holding 1,147 pounds of force, over five times the downward force. (See hammock forces calculator at www.theultimatehang.com.)

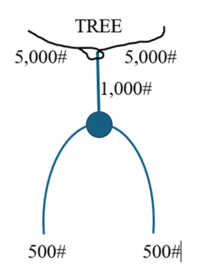

Using the numbers in the above diagram -

-- a 500-pound log held in place through a block

-- exerts 1,000 pounds of force on the rope/strap holding the block.

If that rope/strap is cinched very tightly to the tree and it takes a 95-degree turn at the cinch, rising only 5 degrees, then the force on that rope/strap is over 5,000 pounds.

NOTE: SEE FOLLOWING DISCUSSION WHICH SHOWS THIS LINE OF REASONING IS WRONG!

Last edited: