Maybe a more important question to ask is why you're trying to fell a dying Ash that large, which is a species prone to barberchair even with minimal lean, with such a short bar? Why take the chance? I do not understand the way your brain calculates risk, although truthfully I may understand it and just not agree. You may claim to have had control over that situation but anyone who knows trees knows that you could just as easily have died pulling a stunt like that.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

In the latest episode of “Idiots with chainsaws”

- Thread starter rico

- Start date

Shadowscape

Been here a while

- Location

- far north

See thread title.Maybe a more important question to ask is why you're trying to fell a dying Ash that large, which is a species prone to barberchair even with minimal lean, with such a short bar? Why take the chance? I do not understand the way your brain calculates risk, although truthfully I may understand it and just not agree. You may claim to have had control over that situation but anyone who knows trees knows that you could just as easily have died pulling a stunt like that.

Steve Connally

Been here much more than a while

- Location

- Suffolk, Virginia

Thanks guys for answering my question before the predictable derail happened. Appreciate the info, Time to go grab the fundamentals out of the closet.

evo

Been here much more than a while

- Location

- My Island, WA

I’m enjoying the posted videos under this title. With the exception of @rico, dude I know you’ve done some stupid shit like that uprooting fir in the storm… too bad your videos show straight up tree work

evo

Been here much more than a while

- Location

- My Island, WA

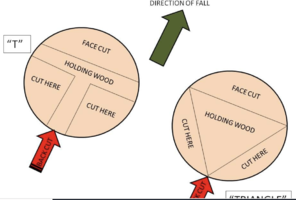

I know I’m late to the game. My understanding of a Coosbay is simply cutting the back cut in a semi circular manner leaving the holding wood to one side till last.

Modifications can include a Dutchman on one side of the hinge, or both sides (remember this is for head leaners going with the lean more or less). Or leaving a strap of holding wood so the curf cross section is looks like a T. Another is leaving a triangle, of holding wood that can be blasted through. One can also cut out the center gutting the hinge as show in the old stihl manuals.

The goal is to leave the least amount of holding wood to cut though BEFORE the tree has a chance to barber chair.

Cutting with a short bar, waiting standing around with a camera until the tree barber chairs IS not a coosbay, if it were the sawyer would be sure to gut enough out there wouldn’t be slow creaking nor need to nibble.

Modifications can include a Dutchman on one side of the hinge, or both sides (remember this is for head leaners going with the lean more or less). Or leaving a strap of holding wood so the curf cross section is looks like a T. Another is leaving a triangle, of holding wood that can be blasted through. One can also cut out the center gutting the hinge as show in the old stihl manuals.

The goal is to leave the least amount of holding wood to cut though BEFORE the tree has a chance to barber chair.

Cutting with a short bar, waiting standing around with a camera until the tree barber chairs IS not a coosbay, if it were the sawyer would be sure to gut enough out there wouldn’t be slow creaking nor need to nibble.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

Your understanding is lacking... It's a pretty simple cut, unconventional, but simple. On a coos bay there is holding wood, but no actual hinge. "Dutchman on one or both sides of the hinge"... That's bad terminology at best...I know I’m late to the game. My understanding of a Coosbay is simply cutting the back cut in a semi circular manner leaving the holding wood to one side till last.

Modifications can include a Dutchman on one side of the hinge, or both sides (remember this is for head leaners going with the lean more or less). Or leaving a strap of holding wood so the curf cross section is looks like a T. Another is leaving a triangle, of holding wood that can be blasted through. One can also cut out the center gutting the hinge as show in the old stihl manuals.

The goal is to leave the least amount of holding wood to cut though BEFORE the tree has a chance to barber chair.

Cutting with a short bar, waiting standing around with a camera until the tree barber chairs IS not a coosbay, if it were the sawyer would be sure to gut enough out there wouldn’t be slow creaking nor need to nibble.

That is not a coos bay... you must be thinking of another cut. Given that you don't seem to understand what a coos bay is, and I do: maybe... just maybe... when I say that I used a modified coos bay on that tree, you could take my word for it... Instead you spout complete nonsense... While I AM used to dealing with a bunch of dumbasses (there you go Sean) on these forums, you are typically not one of them.My understanding of a Coosbay is simply cutting the back cut in a semi circular manner leaving the holding wood to one side till last.

Another is leaving a triangle, of holding wood that can be blasted through.

The goal is to leave the least amount of holding wood to cut though BEFORE the tree has a chance to barber chair.

If you are implying that the reason a coos bay works is becasue the speed of the final cut allows the faller to blow through the final cut before the tree can BC, you don't have a clue. That common mispercption is completely false... The guys over at the treehouse, who like to pat each other on the back for being the best fallers to ever walk the planet, got that one wrong too. They were none too happy when I pointed out they didn't know what they were talking about either.

ANd this video demonstrates just that.. it took 55 seconds from the time I stopped cutting until the the trunk split. When I stopped cutting that tree was ready to go.. would have taken no more than 5 seconds of cutting to trip the holding wood, without the BC. Might have have only taken one or two seconds more. So why did this one take 55 seconds to split? The way this cut performs is not about speed..

For those of you that aren't familair with the species, the white ash is by far the species most prone to BC in the mid-atlantic region. You can see that this one was a monster... but it's harder to tell from the video just how much lean she had. I would call that an extreme front leaner. If this was any other species, it would not have BCed: it would have taken the tree to the lay, before it BCed.

There are a lot of BCs on youtube. I have never seen another one that took more than a few seconds to split. Find one if you can. I'd bet my house that you can't find one that took 55 seconds.

.

Last edited:

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

That's not surprising...Then I rewatched the vid for the third time. I still can't understand why any sort of Coos Bay solution was used. The answer must be in the other segment.

If you look closely at the screenshot, you'll see a kerf undercut was used. It's about an inch under the back cut. There is no point in making a notch when it offers no more control or reliability than a kerf undercut. You could make the argument that a notch would have relieved the pressure and avoided the BC, but I could have just kept cutting and done the same.

From the video description: This cut was made at 5:23 p.m. and all the brush and wood stacked in the cul de sack by 8:23 p.m. So there was no time for fooling around last day of dry weather and a very high end property. I was trying to preserve the lawn. The new Bobcat all wheel steer A300 did an amazing job with this heavy wood. And I did all the cutting with a 24" bar for the entire tree, falling and bucking.

Why the 24" bar? .. becasue that's all I had with me that day.. why the coos bay? .. becasue it's a lot faster and easier, we were running out of daylight and I had to get that wood moved off the lawn before it rained. Why did I stop cutting and let it BC? Because I wanted to see if the coos bay, cut up to that point, was enough to prevent the BC... And becasue I wanted to make an intersting video... I can't run the saw and the camera at the same time.

As it turned out the BC saved a lot of time and effort.. I had just bought a Bobcat A300 which a beast, but the grapple bucket wouldn't have been wide enough to grab those logs, and I would have had to cut them shorter than 8' for the weight, which would have screwed up the log truck.. too short for the bunks... and the 24" bar would have had a hard time making it through that big wood... there may have been some portions of the log greater than 4', in which case it wouldn't have been able to make the cut, and I would have had to leave the site to get a different bar or saw.

We had that wood and all the brush stacked in the cul de sac in 3 hours. The customer came out and asked in amazement "where did the tree go?". Nothing but sticks to rake up...

I doubt any of you would have even tried taking that tree down with a 24" bar... and there is no one here that would have had that wood and brush moved out in 3 hours with the given equipment. I wouldn't have been possible without the BC... Most of you aren't even close... This is way over your heads.... Even you @rico... you think you need a notch for a modified coos bay... when a kerf undercut works just fine and is far easier to cut.

Attachments

Last edited:

Shadowscape

Been here a while

- Location

- far north

Again, I very rarely use a coos bay, but when I do I use the modified version with an undercut because I have found it to be much more accurate when it comes to hitting my lay. Muey importante when taking tops in tight quarters in the woods, or when fanning out valuable mill logs..I doubt any of you would have even tried taking that tree down with a 24" bar... and there is no one here that would have had that wood and brush moved out in 3 hours with the given equipment. I wouldn't have been possible without the BC... Most of you aren't even close... This is way over your heads.... Even you @rico... you think you need a notch for a modified coos bay... when a kerf undercut works just fine and is far easier to cut.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

I never use a coos bay when I need directional control... Usually they're leaning so hard, I wouldn't expect to get much control out of the hinge anyhow. I do have another cut that can turn a heavy front leaner, but only a degree or two in either direction, which is sometimes just enough to make the lay... how far can you turn them with a coos bay?.... and does that mean you're plunging in to set a "proper" hinge, and then just using a coos bay on the back half of the back cut?Again, I very rarely use a coos bay, but when I do I use the modified version with an undercut because I have found it to be much more accurate when it comes to hitting my lay. Muey importante when taking tops in tight quarters in the woods, or when fanning out valuable mill logs..

Shadowscape

Been here a while

- Location

- far north

"This is way over your heads.... Even you @rico... you think you need a notch for a modified coos bay... when a kerf undercut works just fine and is far easier to cut."

"How far can you turn them with a coos bay?.... and does that mean you're plunging in to set a "proper" hinge, and then just using a coos bay on the back half of the back cut?"

Doesn't the question cancel out the statement? Is the supreme expert asking the lesser man for advise?

This just gets better and better the more he spews his bullshit. I really fuck that one up. But it was intentional to save time, and I will explain it that way to make people think I am a felling god, and a teacher of the arb world to all those lesser people. Brother. the crap this guy vomits out. I can tell you I wouldn't want him working with me on a job. Likely get someone killed.

"How far can you turn them with a coos bay?.... and does that mean you're plunging in to set a "proper" hinge, and then just using a coos bay on the back half of the back cut?"

Doesn't the question cancel out the statement? Is the supreme expert asking the lesser man for advise?

This just gets better and better the more he spews his bullshit. I really fuck that one up. But it was intentional to save time, and I will explain it that way to make people think I am a felling god, and a teacher of the arb world to all those lesser people. Brother. the crap this guy vomits out. I can tell you I wouldn't want him working with me on a job. Likely get someone killed.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

I AM questioning him because I want to learn something... to my knowledge, you don't get directional control from a coos bay. Just go back to the page from Jerry's book.. if rico is using a hinge, it's not a coos bay.. if he's not using a hinge, he's not getting directional control... so it may be a matter of definitions..."This is way over your heads.... Even you @rico... you think you need a notch for a modified coos bay... when a kerf undercut works just fine and is far easier to cut."

"How far can you turn them with a coos bay?.... and does that mean you're plunging in to set a "proper" hinge, and then just using a coos bay on the back half of the back cut?"

Doesn't the question cancel out the statement? Is the supreme expert asking the lesser man for advise?

This just gets better and better the more he spews his bullshit. I really fuck that one up. But it was intentional to save time, and I will explain it that way to make people think I am a felling god, and a teacher of the arb world to all those lesser people. Brother. the crap this guy vomits out. I can tell you I wouldn't want him working with me on a job. Likely get someone killed.

Jerry B says you can't get directional control from the coos bay... if rico is really using the cut to "fan out" logs for lumber he's got some splainin' to do... I don't work on those monster west coast trees like Rico, but I still can't see the need for using a coos bay once the top is out. It doesn't make sense. But I try to keep an open mind...

Treetopflyer

Been here much more than a while

- Location

- Coastal N.J

Daniel I think a lot of the things you’ve done are intense with a lot of risk involved and I can understand a desire to want to learn through trials and errors I think you’ve been at it awhile and appear in that video very complacent to the danger because your experienced. Said that you can set up a camera and make that cut or put a go pro on your head without showing people chilling by the barber chair danger zone putting your back to it showing people who don’t know better could get them hurt even though your good enough to do so or lucky enough so far ...basically inducing a barber chair in a one off non practical way or I’ll say in no way very repeatable so therefore useless , with this massive you say 4 foot fat my aasssh.. maybe 36 maybe little bigger inch head leaner by the look of the vid where you seemed awfully surprised at the end with your OOHh BOY stunned reaction made me chuckle and led me to believe you had little control over the situation. I try to keep an open mind , you looked unprofessional and very complacent in that one if we’re talking idiot with chainsaw thread, with no sound or context it could fit the bill

Shadowscape

Been here a while

- Location

- far north

Why would you want to learn something from a man way under your head? ("This is way over your heads.... Even you @rico")

You are nothing but a warehouse of bullshit.

But Rico will be nice (unlike you) and explain it to you. Me? I wouldn't give you the time of day.

You are nothing but a warehouse of bullshit.

But Rico will be nice (unlike you) and explain it to you. Me? I wouldn't give you the time of day.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

If you want to criticize my work, there's 600 videos of it on youtube... find one... you guys talk a lot of crap. I've shown the work I do for 14 years.... And I've seen what Rico can do... he's the real deal... but are you? I haven't seen what you can do... other than take lovely pictures of naked women... You can type whatever you want into a keyboard, but until I see what you do with a chainsaw, it doesn't mean a thing. Anybody can throw mud.. let's see you put a tree on the ground.. And I'm still waiting for Sean @southsoundtree , or anybody else, to find a video of blowing out big tops published before 2010.I wouldn't want him working with me on a job. Likely get someone killed.

Rico knows his shit... and he works on much different (taller) trees than I do... I have learned some things from him, and want to keep learning if he's got some knowledge and expereince to share. And there is nothing wrong with having differences in opinions... There's a lot of ways to skin a cat. Let's talk about it and let everyone take from it as they see fit.

In the meantime for your viewing pleasure here's a trick shot from back in the day...

Last edited:

Shadowscape

Been here a while

- Location

- far north

There are 600 videos on YouTube of idiots with chainsaws. There are 600 videos on YouTube of people sticking weird things in their ear. Doesn't mean shit. I don't try and make people believe I am some super tree guy by making YouTube videos. I will leave that nonsense up to you. And I certainly am not going to watch another one of your idiotic videos above.

Thats why its called a modified Coos..A standard shallow undercut and proceed as directed. And yes, you do have directional control with this cut.I AM questioning him because I want to learn something... to my knowledge, you don't get directional control from a coos bay. Just go back to the page from Jerry's book.. if rico is using a hinge, it's not a coos bay.. if he's not using a hinge, he's not getting directional control... so it may be a matter of definitions...

Jerry B says you can't get directional control from the coos bay... if rico is really using the cut to "fan out" logs for lumber he's got some splainin' to do... I don't work on those monster west coast trees like Rico, but I still can't see the need for using a coos bay once the top is out. It doesn't make sense. But I try to keep an open mind...

Obviously you have never chunked down 20-30 foot redwood mill logs on a hard leaner. Then you would understand just how linear the grain on redwood is, how prone it is to splitting vertically, and just how far they can split. I believe thats why they were historically used for shakes/shingles and split rails.

Again, not a cut I employ very often, but in the tool box when the need arises.

Daniel

Carpal tunnel level member

- Location

- Suburban Philadelphia (Wayne)

right that all makes sense.. thanks for the clarification.... that's what I thought you must have meant. where did you get the graphics?Thats why its called a modified Coos..A standard shallow undercut and proceed as directed. And yes, you do have directional control with this cut.

Obviously you have never chunked down 20-30 foot redwood mill logs on a hard leaner. Then you would understand just how linear the grain on redwood is, how prone it is to splitting vertically, and just how far they can split. I believe thats why they were historically used for shakes/shingles and split rails.

Again, not a cut I employ very often, but in the tool box when the need arises.

View attachment 91982

evo

Been here much more than a while

- Location

- My Island, WA

Might want want to retract your comments made towards me, aye? Who is the clueless one?right that all makes sense.. thanks for the clarification.... that's what I thought you must have meant. where did you get the graphics?

On the interweb..I think it was on arboristsite. Not a fan of that site, but they had a good graphic of a modified Coos. I generally do the triangular version because I find it much easier to perform, and get good result with it.right that all makes sense.. thanks for the clarification.... that's what I thought you must have meant. where did you get the graphics?