TreeCo

Carpal tunnel level member

Vector Calculator

Math explained in easy language, plus puzzles, games, quizzes, worksheets and a forum. For K-12 kids, teachers and parents.

www.mathsisfun.com

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Of course I do. There are many variables such as tree height and back lean.You realize higher and more horizontal are traded off one for the other? in the OP configuration. Alone each is true. The tradeoff was the gist of the original question.

45 degree 1:1 tie height to swat zone, but the top reaches further but#2 ground pullers can walk with the rope for a manual pull, outward from the swat zone.

Here's some solo pulling. Basal tied pull rope, redirected through a block on another tree down low, back to a masdam on the stump of the tree I'm cutting. Notch above the orange line so I can crank the masdam. The long throat on the orange sling is to avoid the butt of the tree smashing the masdam when it falls. In a similar vein to the question posed in this thread, the direction of pull does not need to pull 100% in the direction of fall. As long as there is a "forward" component to the pull, you should get forward movement. In the pic, the tree will fall 30 degrees to the right of the line the masdam sling is pointing.Sean works solo a lot, so cannot be behind the tree and on the machine.

That's a great solo setupHere's some solo pulling. Basal a tied pull rope, redirected through a block on another tree down low, back to a masdam on the stump of the tree I'm cutting. Notch above the orange line so I can crank the masdam. The long throat on the orange sling is to avoid the butt of the tree smashing the masdam when it falls. In a similar vein to the question posed in this thread, the direction of pull does not need to pull 100% in the direction of fall. As long as there is a "forward" component to the pull, you should get forward movement. In the pic, the tree will fall 30 degrees to the right of the line the masdam sling is pointing.

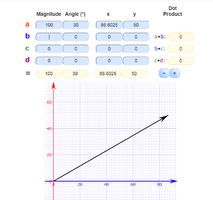

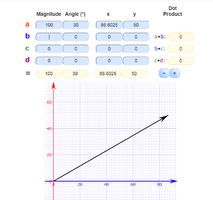

I like Excel, so here are the figures in a spreadsheet.One case:

-fixed distance between winch and base of the trunk of the tree (base)

-variable/choose height up the stem (L) you attach the rope to form rope angle above horizontal (theta)

calculate:

L/base = tan(theta) so L = base x tan(theta)

component of rope tension that makes torque is tension x cos(theta)

torque is tension component x lever arm = tension x cos(theta) x L = tension x cos(theta) x base x tan(theta)

tension is a constant, base is a constant, only theta changes (which directly makes L)

so when the quantity cos(theta) x tan(theta) is the most/biggest you get the most pull over torque

Who wants to make a spreadsheet and run the angles? feeling lazy

do cos(theta) x tan(theta) = and put angle values in for theta

did - hand calculatored, 35 deg .57 and it kept on improving up to 80 deg .96!!! seems the gain on L outdoes the loss on cos(theta) bad pull angle. Now at 80 deg L is 5.67 x base that's one hell of a tall tree. Surprising result - go as high as possible. With practical constraints of course.

Teacher, can you check my homework for mistakes?

edit - values by hand

theta cos(theta) tan(theta) cosxtan = relative amount of torque from fixed base and fixed tension

15 .97 .27 .26

25 .91 .47 .42

35 .82 .70 .57

45 .71 1.0 .71

55 .57 1.43 .82

65 .42 2.14 .90

75 .26 3.73 .97

80 .17 5.67 .96

table spacing nuked when posted! doh!

cos theta is being close or not to a perpendicular pull

tan theta is L up the trunk (as a # x base), the lever length

cos x tan is the torque generation factor as a function of fixed base and varied theta.

Most guys probably work in the sub 45 range unless there's plenty of room.

note 45 to 55 - 43% higher up stem but only 11/71=15% more torque. bit of a losing proposition per setup effort

Yes. It also puts one in the swat zone.Is 45 degrees rope angle the break even point, beyond which we have diminishing returns?

The math is just algebra and trig. It says to go as far away as you can and high as is safe to get the most torque out of your pull.Or is the math more complicated than that?

Yes. It also puts one in the swat zone.

that's irrelevant.. by the time the tree gets moving it's going to quickly outpace any pull line no matter how high or low. Sean' video is a good example of that... That log hot the ground early in the fall... a that point the pull line had zero effect. I only learned this from watching my own videos. The pull line goes slack early in the fall.... EVERY TIME...The lower the rope the longer the rope pulls through the fall.

no... backleaners need high pull lines... best to pull with vehicles if you need speed... good drivers needed.. though likely just a differenc based on te difference inthe trees we work onOf course I do. There are many variables such as tree height and back lean.

A fair standing tree where one wants a little extra control with a tag can have a functional tag line 1/4 up the tree.

Heavy back leaners one wants a tag as high as functionally possible and the pulling point to be far.

Leverage is also a huge factor as well as desired speed of pull.

Heavy back leaners are best pulled with speed after they are cut up, this speed is often gained by lower points and more horizontal pulls. This of course is at the sacrifice of leverage multiplier, so requires a stronger pulling force.

Experience to read the sweet spot..

Please re read what I said and if I wasn’t clear ask a question.no... backleaners need high pull lines... best to pull with vehicles if you need speed... good drivers needed..

It's likely that our different perspectives have to do with the differences in the trees we work on.Back leaners need speed, they also need leverage. There is a sweet spot, if you have power you can go lower for more speed.

All good.. I like the technique.. definintely adds a LITTLE more time to the pull...Yes, the log hit early in the fall.

The log pulled longer that the pull rope alone. That was the point.