chiselbit

Been here a while

Do you guys remember oldfart? He did a stump pulling video with a bunch of mechanical advantage, everything moving slow and then pow! Stump exploded out of the ground.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

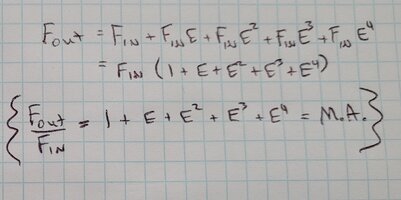

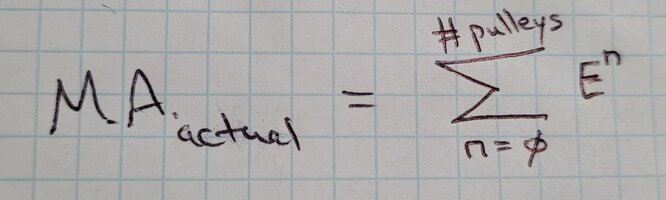

I think that's 4.33 / 5 = .866 or 86.6%. think that's typical. Super efficient stuff will be 4.5+:1Maybe I'm thinking of this wrong, but does #4 being 4.33:1 mean that - if all loss is in the pulleys - that those pulley's are 96% efficient!? Holy cow. Before I did all the other calcs, I looked up some typical pulley efficiencies, and was seeing numbers in the 85-95% range.

Obviously I've got some learning, listening, and thinking to do. Thanks for the word.I think that's 4.33 / 5 = .866 or 86.6%.

Learning here too. Muggs does some good work!Obviously I've got some learning, listening, and thinking to do. Thanks for the word.

He still around?Do you guys remember oldfart? He did a stump pulling video with a bunch of mechanical advantage, everything moving slow and then pow! Stump exploded out of the ground.

. . . Tom Hoffman's video on tractor stump pull on his YouTube channel . . . pop went the stump!Do you guys remember oldfart? He did a stump pulling video with a bunch of mechanical advantage, everything moving slow and then pow! Stump exploded out of the ground.

| Stage | Input Force (kg) | Input Force (kN) | Efficiency Ratio | Output Force (kg) | Output Force (kN) |

|---|---|---|---|---|---|

| 1 | 25 | 0.245 | 0.85 | 106.25 | 1.042 |

| 2 | 25 | 0.245 | 0.85 | 454.69 | 4.452 |

| 3 | 25 | 0.245 | 0.85 | 1,946.29 | 19.065 |

Can you ask it to show its math? I'm not getting anything that agrees with this, and with it being a "black box" (that is, we can't see what's going on inside), there's no way to see how it's arriving at its conclusions.Friendly AI back again...

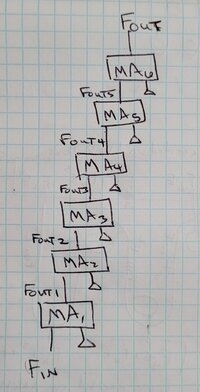

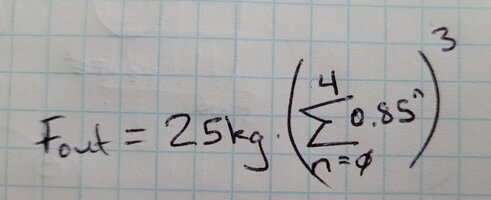

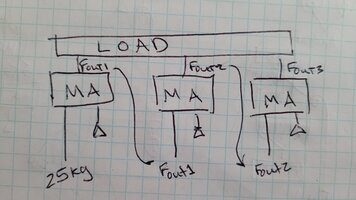

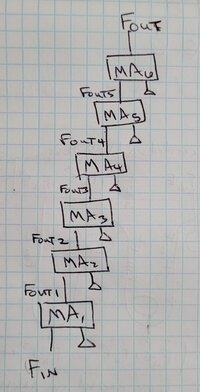

me>I want to run a new scenario. I this scenario, I want to analyze 3 5:1 systems. Each system will have a constant input load of 25kg applied to it. The output force of the entire system will compound the previous stage's output force as it's applied sequentially. Each 5: 1 pulley and rope system is 85% efficient. I'd like to see a table with the stage number, input force in kg and kN, the output force in kg and kN and finally a total force of all 3 systems in kg, lbs, and Kn specifying that the calculations were done at the efficiency ratio provided.

ai>

Sure, here is the table with the requested information:

Total Force:

Stage Input Force (kg) Input Force (kN) Efficiency Ratio Output Force (kg) Output Force (kN) 1 25 0.245 0.85 106.25 1.042 2 25 0.245 0.85 454.69 4.452 3 25 0.245 0.85 1,946.29 19.065

Note that the calculations were done at the provided efficiency ratio of 0.85.

- in kg: 2,507.24 kg

- in lbs: 5,522.53 lbs

- in kN: 24.56 kN

My notes:

I *think* this is right - it look AI about 6 tries to get to this - with subtle wording changes in each attempt to have it compound the output forces properly.

It is - I'm just looking at each 5:1 system as a whole and not worried about each pulley. There is an input, output and some losses. The ratio accounts from all losses, regardless of from pulley design, rope, or other sources.It's not treating each pulley as 85% efficient, it seems, but rather each entire system as 85% efficient (5:1×0.85 = 4.25:1). Maybe that's what you intended though.

Total load is all 3 pulling on the load - the sum of the 3.The output in the table - 1,946kg - also does not match the output in the table summary - 2,507kg.

I *think* it's compounding the in(efficiency) at each stage...so the 85% output gets added to and then treated as 85% again at the next stage making the previous stage even more inefficient. My thinking was that's probably real world - that those things do add up, but maybe not like it's calculating.Treating each entire 5:1 system as 85% efficient - as the AI seems to be doing

I'll try lol...I think it's starting to get irritated...Can you ask it to show its math?

For sure...it's not ready yet...honestly, it's pretty amazing that it can provide these responses given the input I gave it - as it gets 'smarter' over the next year or two, it will be crazy. Put it in a robot or two, and it's time to head to the bunkers lol...It's wild

| Stage | Input Force (kg) | Output Force (kg) | Output Force (kN) |

|---|---|---|---|

| 1 | 25 | 106.25 | 1.04 |

| 2 | 25 | 453.13 | 4.44 |

| 3 | 25 | 1928.91 | 18.91 |

| Total | 75 | 2488.29 | 24.39 |

106.25kg × 5:1 × 0.85 = 451.6kg

me>is math hard for you?AI: Output Force = 106.25 * 5 * 0.85 = 453.13 kg

I'm feeling way less threatened by AI now. Thank you.me>is math hard for you?

ai>As an AI language model, I don't really have feelings, so math isn't hard or easy for me. However, like any machine, I can make mistakes or misunderstand instructions. If you notice any errors in my calculations or responses, please don't hesitate to let me know and I will do my best to correct them.

I apologize again for my mistake. You are absolutely right, the correct calculation is:

106.25 * 5 * 0.85 = 451.56

So the output force at the first stage with an efficiency of 85% would be 451.56 kg, not 453.13 kg as I previously stated.

Thank you for your patience and for bringing this to my attention.