Life on a Line is a remarkable background work, original version was free.

.

Radial friction compounds; different compared to linear/flat friction linear progression.

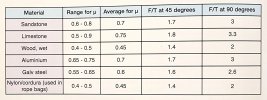

Both use the same standard CoF numbers for mated surfaces available at several sites , even gov tables as accepted standards.

EngineeringToolbox table example.

.

For round capstan frictions etc. tho, you take that same flat linear mated surfaces CoF rating (above) X pi (as to now have a radial friction CoF value for the same 2 mated surfaces in table) X number of 180 degree units (like 1 stroke at that CoF each, 2nd 180 stroke would be completing a mechanical cycle) instead of a multiplier of contact distance like would think.*

Then, this sum is a COMPOUNDING EXPONET of 2.718281828....Euler's number (the E key on many calculators as a defined math constant like PI); approx. Logarithm of 1 as used similarly in calc compounding interest, population growth, decay etc. Euler also publicised mathematicians PI symbol usage outside the math geek club to the public and many other contributions as well.

.

Linear/flat friction is simpler calc weight, friction, distance. Simplest flat model see the direction of linear movement as cosine(target work)and friction as 90 degree tangent sine(byproduct of cos work achieved model). Separate dedicated uses of cos/sine, ONLY sine factor used for friction. Radial friction on capstan is different animal right there, cuz uses cos+sine together to power radial friction instead. i say again, ALL physical displacements against space or force can be decoded to cos/sine as the Natural organic pattern of expression for displacements. Every change or even potential to, can be shown as a displacement(key term). And radial is always different than linear considerations in all of this.

.

This radial cos+sine in arc is same science that makes bridge and dome arcs so good, the arch in architecture, and the linear cos or sine used separately is the weakness; in all materials. Stone (w)as most sensitive sensor/witness to this w/deflected tension tolerance (sine) only 10% of compression(cosine of downward force load value) on horizontal. To work in stone so, they had to find the arc or crumble!

.

i put this together some time ago, radial friction table most matching topic.

Spreadcheat

I found .25 nylon/aluminum CoF and few others relevant to rope as stated,(nylon/steel .4, hemp/wood .5 etc.)but honestly sources have faded out. Including this very comprehensive work to this topic:

"Mechanics of Friction in Rope Rescue " -Dr. Stephen Attaway

.

* The calc of capstan frictions are by degree not linear distance, so smaller capstan varies to harsher rope arc and the same frictions but heat byproduct concentrated into smaller area. Aluminum is better heatsink than steel, wood an insulator of course. If electrical conductor or insulator is same for thermal; except diamond as thermal conductor but electrical insulator )