eyehearttrees

Not a new Member

- Location

- Tampa-Area

Just an FYI from several discussions with Harken (the maker of the X Rigging rings/Safebloc) they haven't actually been able to replicate the whole crack fraying the rope thing. I have heard from Treestuff that it's possible but only in discussions comparing the X Rigging rings to the unfinished Notch rings. They usually also mention that the unfinished rings can be made smooth again by a light sanding where any damage to the X Ring is permanent.

X-branded rings are Antal not Harken, no? Quite sure that's the case, unless antal=harken or something..

And that's true Re permanence of damage although as I mentioned I think that >5yrs of people bombing wood down with these rings, w/o a glut of people posting their worn-out rings online, is incredibly telling!

Very curious about the harken/antal thing though as I thought Harken was distinct, I knew antal made the x-rings but was never sure who made the Safebloc (I know xman created it but wasn't sure who was producing them) Really wish these companies would do a "more for less" pricing approach IE that the increased sales from more units could offset lower per-unit profits, having the large rings at $80 price point is nonsensical it's a large aluminum washer lol

Having said that when we had Harken make the big ring their way for us (with their logo on it because it looks way cooler) we collectively decided to do the harder, shiny coating on it instead of the matte finish. It feels a lot like the finish on the Safebloc. Was more of a function vs fashion thing. We have not been able to replicate this "cracking" thing on that or the smaller sizes. I'm sure it's possible but you would have to be pretty hard on the gear. Hope that helps.

-Jason

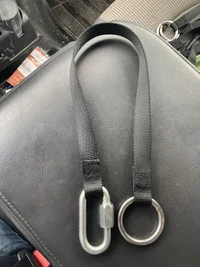

Re finishes you've got things twisted (or I'm misinterpreting you!) again....X rings come in matte finishes and gloss finishes, I've got the 3-ringed sling (1 XL ring, 2 Lrg rings) and the XL ring is gloss the Lrg rings are matte (maybe that's exacerbating the problem of the center ring lifting&squishing when under load!), I've also got a Safebloc and it's most-certainly the same exact matte finish as my Lrg rings are (I would say 'unless they changed it' but I've never seen a pic of the Bloc with the gloss anodization, only with the matte anodized finish)

Re form-versus-function on anodization-type, can I ask what testing you did? This has always intrigued me IE how much more friction would I get from having non-anodized rings, or from using matte anodized instead of gloss anodized? Even if you aren't able to provide #'s it'd be very illuminating to know what differences were observed, in-practice, between matte&gloss anodized coatings! Thanks