Had always thought length-of-rope in system made dyneema especially dangerous for these cases? (ie cases where dynamic-loading - fall-arrest, here - and short rope-length are both prime factors)

I get that dyneema > nylon for static strength, but nylon hitch cord is plenty strong for all the non-dynamic-usage you're gonna give it....and it's got some cushion/capability if subjected to shock-loading ie you falling, I don't get the logic of "give-up the raw dynamic-strength of nylon, to increase static-strength of a product that already had insanely high static-strength"..

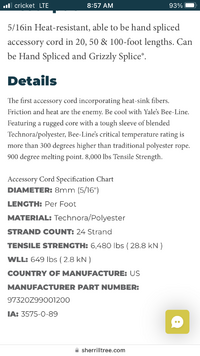

Just curious! Almost every hitch I own is Ice Tail eye&eyes or knotted loops, though if/when I find a comparable hitch made of something more dynamic I'll be swapping (would love if they just did an aramid/nylon blend for moderate heat-resist & high-dynamic strength, just in finding this thread I realize that, unlike my old Epicord//Blue Moon combo, now my hitch is my weak-point in my Ice Tail//Mercury combo -- even though Ice Tail//Mercury are both 8.5k lines, the 3.5% v 1.05% elasticities makes a *massive* difference in effective dynamic-capacity)

(PS- and I know "these are way stronger than your body anyways", and when new and used optimally that's true, but goal should be optimization and, once a hitch-cordage is 5k+ ABS tensile, IMO a better attribute is dynamic-capacity not increased-static-strength AKA swapping from a poly/nylon blend to a dyneema product)