Hate to be the guy to pee in your Kool Aid but PVC really shouldn’t be used for compressed air.

www.osha.gov

Just google PVC compressed air and you get all kinds of OSHA bulletins on this. The main reason I have a problem with it is firstly because it is not meant to be used for compressed gasses. Second, tree guys are hard on things and at times push the limits. Can’t get that shot, keep pumping a little more. How many PSI can it take for how many times? How about when exposed to UV and heat cooling cycles in a vehicle? And how many cycles to failure does PVC have?

I used to do a lot of repair on PVC doing sprinkler system installations and modifications. Saw a lot of broken pipe and often times in shards. As someone legally blind in one eye, I will not work around people using air cannons made with PVC rather than metal and certainly wouldn’t allow it on my job site.

Lastly, don’t you think if PVC was suitable for this, that the manufacturers of these things like Treestuff would be selling you an all plastic APTA assembled in China for $3 and they would charge you $49.99! Have one of these things blow up in your face and no matter how big of a laser sight it has on it you won’t be able to see it.

Listen, I respect where you’re coming from, but hear me out on this all…

What started this was looking on YouTube and such and seeing guys building throw bag launchers out of 2’ sections of 1.5” PVC with a 3/4-1” ball valve and I’m hearing pressures of 100-175 psi, which honestly kinda worried me. Sure, PVC has ratings on the pipe and 1.5 is listed at 320 psi, 4” at 220 psi, the 2” ball valve at 150 psi…

I wanted to build a metal one, galvanized pipe and the works. Stainless would have been really sweet but for sure out of budget. Then I priced out building a metal one and it was not really budget friendly either. I also was undecided as to precisely how I wanted to put the metal one together, do I do a Treestuff APTA knock off? Or do I experiment with modifications?

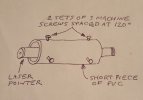

PVC seemed like a good place to start, for the same money I would spend on an APTA knock off, I could make a couple different PVC ones and some more in-depth testing before I build anything metal. I also thought that I could make some modifications to the design. Granted, what I ended up building, made of metal, would be uselessly heavy, but I’m not done yet with building and testing either. I’m building one, spending time here and there testing and playing around with it, posting it places and gathering input, then moving on to the next. Consider it gathering some more extensive information. R&D stuff.

Back to where I had been looking at how other people did it. The valve I saw as a potential restriction right off. We aren’t trying to power an air tool, we are trying to impel force as quickly as possible to the throw weight before we run out of barrel at which time acceleration stops and deceleration begins. The shorter the barrel, the less time you have. The smaller the valve, the slower (relatively) the air can move past. To some degree higher pressure can compensate. But that brings us to more pressure and something else that I was attempting to reduce, even with a metal one.

So I borrowed a page from pumpkin chucking contests. There are two main schools of thought with the air powered pumpkin chuckers. High pressure/low volume (your typical APTA and knock offs), or low pressure/high volume. I went rather large to start, in an attempt to reduce pressure by increasing volume and to help the bag along in a low pressure scenario, a longer barrel. I was initially worried that a 2’ long pressure chamber would not be enough to yield a significant drop in pressure so I made it modular where I could thread on additional length. I was venturing into uncharted territory with this all so I needed data. I have been rather surprised by the results.

The pressure chamber has always been my worry, it’s naturally the most dangerous part of this. I consider the valve as part of this assembly if you will. The barrel is largely a non-issue as to being of PVC, it really never sees full pressure because the throw weight is moving down it when the valve is released. I did initially have a concern about the space between the bag and barrel possibly being a problem of some sort, but I have a piece of heavy gauge wire at the bottom of the barrel to prevent any chance of the bag potentially getting wedged there which could cause a pressure spike. The lower pressure air then filling the space seems to be a non-issue.

With 70 psi in the first (and largest) I built being capable of putting a 16 ounce weight above the trees here, my concerns about the PVC holding are minimal. I would be a lot more concerned about 150 psi which is what a lot of people on YouTube are doing. That’s a far smaller safety margin. I don’t leave these charged up even being a much lower pressure. The pipe was cleaned, primed, and glued with high pressure solvent and let stand for over 24 hours before use. They are stored out of the sun and heat with the valves open. Sure, eventually even that won’t be enough to keep them from becoming brittle, but they will last long enough for my purposes.

I’m not having a bunch of gorillas manhandle them around a truck toolbox and job site so I’m not particularly worried about damage from rough handling. I’ve always taken great care of my tools and gear and this is being used more on an amateur level. I’m not a professional arborist and don’t really intend to be one. I do however like learning useful things and tinkering/experimenting. Sometimes I’m successful with a project but it’s not practical for everyone. My big PVC air cannon could certainly be made of metal. Heck, to even cut weight down you could probably safely use a PVC barrel even in commercial settings. But the air chamber and valve assembly is going to be a heavy chunk of steel, which likely would ruin most practicality for commercial use. For me however? Well, it would be something I could deal with.

Now, my experiments with making smaller versions does start to open up more possibilities. But I couldn’t just jump down to an APTA size without gathering more information. I wanted to see how a size reduction would affect performance. So I cut the air chamber in half and shortened the barrel by a foot. At that point I was still expecting good performance with reasonable pressures, which I apparently got. I’ll have to test it some more, but I was actually surprised to note that there appears to be a linear change. Half the air chamber size required twice the air for the same results. I sort of expected some non-linear change or an indication of a bell curve. If testing bears that out, there will be another, yet smaller, build. But it will be based on calculations from the first two. If that follows suit and performance is directly related to the first two, then I’ll be able to calculate how to build air cannons, metal or otherwise, to meet certain performance requirements.

I also want to experiment with valves when I can to see what that can do. Maybe I can come up with a design for a metal one that beats everything on the market while remaining practical for commercial use. Maybe I can’t and just end up with a bunch of experimenting and a lot of fun doing it. I haven’t really thought that far ahead yet, I’m just having fun with tinkering and seeing where it leads.