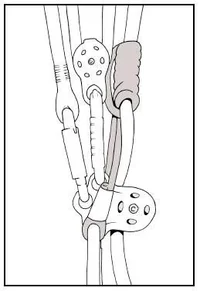

If the third hole is not a bennefit to your climbing style then the flared cheek plates for less friction while fair leading will be a plus. Also the holes for the connecting links are smaller so the link can not do a three sixty. Plus if you use oval kinks and they move they seem to move back to a correct position when you load them. Seems like a huge safety plus.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hitchclimber

- Thread starter Rookieclimber

- Start date

NickfromWI

Participating member

- Location

- Los Angeles, CA

- Location

- Bloomington, Indiana

[ QUOTE ]

[ QUOTE ]

That would be a good idea for me, however in the states we need to have a self-locking biner for any life support application.

[/ QUOTE ]

says who?

Maybe for competitions, ...

[/ QUOTE ]

Just for the record, ANSI Z133.1-2006 says that you have to use self-closing, self-locking biners for tree work in the U.S.

Competitions generally require a competitor to follow the standards from the region where the comeptitor works.

[ QUOTE ]

That would be a good idea for me, however in the states we need to have a self-locking biner for any life support application.

[/ QUOTE ]

says who?

Maybe for competitions, ...

[/ QUOTE ]

Just for the record, ANSI Z133.1-2006 says that you have to use self-closing, self-locking biners for tree work in the U.S.

Competitions generally require a competitor to follow the standards from the region where the comeptitor works.

treebing

Been here much more than a while

- Location

- Detroit, Mi.

Well, i stand corrected. Hmm, that seems to me to be one of those rules made up not because of real data but someone just getting creative about possible dangers. Maybe Im wrong there. I almost never use one but I am confident in their safety.

Rupe, I tried your system out today. I think that I am a reach around the back climber. It was a cool way to set it up. I have been playing around with the mickey mouse pullry and have not real satisfied because of the splice catching my hitch, as well as not being able to pull the lines apart.

Rupe, I tried your system out today. I think that I am a reach around the back climber. It was a cool way to set it up. I have been playing around with the mickey mouse pullry and have not real satisfied because of the splice catching my hitch, as well as not being able to pull the lines apart.

- Location

- Watertown, WI

i tried the mickey mouse pulley and the only hitch I was able to use was a VT. I am not a fan of this hitch due to a bad experience as well as liking the effect I get with a short hitch so I dont have to sit back 6 inches to set the hitch.

NickfromWI

Participating member

- Location

- Los Angeles, CA

Rupe's setup involves tying into the becket of the slack tending pulley. It seems like the jury is still out on whether or not that is acceptable, no? I won't do it.

love

nick

love

nick

- Location

- United Kingdom

Ultimatly I don't want anyone to tie into the becket particularly. I checked the safety issues as much as possible before posting. The idea was to prove to myself really that having the standin gpart behind the friction hitch works better for me at least.

The HC should be considered as far more than a slack tending pulley, its part of a whole system for the arborist and if it works as slack tender then its got to be good for everyone due to its other application, of which my method has no other applications!

The HC should be considered as far more than a slack tending pulley, its part of a whole system for the arborist and if it works as slack tender then its got to be good for everyone due to its other application, of which my method has no other applications!

Chris

The HCGTTG states how loads are applied to the karabiners, as if there is an issue. As the Forestry Commission prusik research shows, there is no real issue with karabiner strengths. The loading diagramme of 1/2 1/4 1/4 also don't correspond with my experiences of the prusik testing in arborist set ups. There are huge variables in the way prusiks grip and load the line.

Karabiners used in treework are plenty strong enough to cope with the typical forces applied in DdRT. Choosing the correct type helps. This is a training and education issue.

The loading at which a prusik will grip a line will also vary depending upon how it is set. Again, this can be seen from the FC prusik research.

Good to see another friction cord with polyester core and aramid/polyester fibre blend sheath. Again, this was a proposal of the FC prusik research. Personally, I no longer favour the aramid/polyester sheaths, because I find they transfer heat to the lifeline instead. Maybe the Ocean is different, I'll have to try. I prefer to melt and replace a polyester prusik as necessary. A knotted system keeps the lines apart and grips the karabiners to prevent rotation.

These comments are with regard to safe working systems. Nothing to do with hitch Climber - IMHO it seems a great little tool, particualrly the fair leading design.

I just wanted to reassure others that standard micro pulley hitch systems are just as versatile without inherent safety issues that the HCGTTG implies.

The HCGTTG states how loads are applied to the karabiners, as if there is an issue. As the Forestry Commission prusik research shows, there is no real issue with karabiner strengths. The loading diagramme of 1/2 1/4 1/4 also don't correspond with my experiences of the prusik testing in arborist set ups. There are huge variables in the way prusiks grip and load the line.

Karabiners used in treework are plenty strong enough to cope with the typical forces applied in DdRT. Choosing the correct type helps. This is a training and education issue.

The loading at which a prusik will grip a line will also vary depending upon how it is set. Again, this can be seen from the FC prusik research.

Good to see another friction cord with polyester core and aramid/polyester fibre blend sheath. Again, this was a proposal of the FC prusik research. Personally, I no longer favour the aramid/polyester sheaths, because I find they transfer heat to the lifeline instead. Maybe the Ocean is different, I'll have to try. I prefer to melt and replace a polyester prusik as necessary. A knotted system keeps the lines apart and grips the karabiners to prevent rotation.

These comments are with regard to safe working systems. Nothing to do with hitch Climber - IMHO it seems a great little tool, particualrly the fair leading design.

I just wanted to reassure others that standard micro pulley hitch systems are just as versatile without inherent safety issues that the HCGTTG implies.

- Location

- Rannoch, Scotland

Paolo

I think we are not so apart on this one! But my answers to your points have to be ‘Jein’ i.e. neither Ja nor Nein!

In the ‘Ropes and Friction Hitches Used in Tree Climbing Operations’ document that you refer to it states under ‘Testing Setup and Procedures’:

‘At an early stage in the testing it was established that a single [attachment] karabiner was the weakest link in a typical doubled rope system. Once this had been established, the climbing line termination (typically a bowline) and friction hitch loop were placed directly into the 16mm shackle on the ram and load cell. Friction hitches that required a separate karabiner were set up as in the field, the friction hitch being attached to one karabiner and the climbing line to another. Alternatively, the climbing line was terminated in a bowline and anchored directly to the shackle.’

This suggests to me that the above research and ours have tested karabiners in different ways. We found that HMS shaped karabiners were, on the whole, better at tolerating wide loading than Offset D shapes. However, even with HMS ‘biners, there was a significant loss of strength due to wide loading, in particular the placing of half the load furthest from the spine/back. Our ‘bottom line’ was a configured strength of 15kN for 3mins, which is essentially what all Euro PPE is required to meet. Some of the combinations we tested did not meet that standard.

Because of these results, and further tests on karabiners used in a choked configuration, we set about trying to come up with a simple system where the karabiners were configured how they are designed for testing, hence the Hitch Climber pulley is part of a system.

[Treemagineers have presented the results of various karabiner tests at an arborists gathering in Augsburg, Germany and at TCI and/or ISA for the last three years. My goodness you must be bored of hearing that stuff by now!]

Your point about karabiners being fine for typical forces is, of course, correct. We just thought it couldn’t be a bad idea to try to cater for those occasions when things go a bit ‘Pete Tong’.

Something worth bearing in mind is quality assurance in the manufacturing process. All of the connectors we used in our tests were from ‘reputable’ manufacturers. Over the last few years I have heard of tests on ‘other’ karabiners where the breaking load was down as low as 9kN (quoted as 22kN+). These tests were ‘best case scenarios’ i.e. 12mm pins at each end of the connector. And before you all jump down my throat saying that I am scare mongering, I am not. The issue is real. This scrap metal is more widely available than you may think. And no, I won’t be drawn into giving names…..for very obvious reasons. So please don’t ask! A bit of brand loyalty may not be silly!

A discussion later in the FC document (which follows the failure of a doubled rope test of a four coil Prusik at a peak force of 2223kg) says:

‘If both the lifeline and friction hitch are connected to one karabiner, the karabiner (minimum 22kN BS) is the weak link, but a substantial 22:1 safety factor was recorded.

The only point I would pick up on here is that you have used the mass of the ‘climber’ as the basis for your calculation of the design factor. If the peak force generated in a fall were used, the design factor would be much smaller. In these situations, the poor configuration of equipment can be quickly exposed.

Our testing shows that the Petzl OK used as the main attachment ‘biner in an HC system with stitched OP e2e slings has a configured strength of ~28kN (~6200lbs). All the other components are also used as designed and tested.

Re the specification of hitch cord, the FC report suggests:

….there is much scope for specific cords to be designed with suitable strength (1700Kg would be ample), but with high external heat resistance and good knotted strength. For example, a cord with a braided core of polyester and a jacket of aramid fibre would, theoretically, solve the problems associated with residual knotted strength and heat resistance.

I note your point in your post that there is scope for heat resistant fibres in the hitch cord mantle to cause heat damage to the climbing line. You are correct, but this must not happen, and responsible safe climbing will take care of this issue.

At the start of our hitch cord testing, we thought that abrasion resistance was the key parameter for hitch cord. But with the switch to smaller diameters (climbing line and hitch cords), less friction at the anchor and an increasingly sporty climbing style, this is perhaps no longer the case. If a ‘big unit’ decides to ‘swing and dump’ whilst using small cordage, heat is more likely to be the issue than abrasion.

OP is 75% Polyester. The Aramid is in the right place for when/if you may need it. Our running rope/heat resistance tests indicate a large safety reserve is provided by the Aramid component, when compared to pure Polyester hitch cords. The aramid protects the polyester from most of the heat build up, so that the Polyester can continue to provide grip for longer. In this way, pricey cords with a ‘hi-tech’ component can be very good value for money when compared with cheaper, lower performance cords. This info was presented at the Augsburg Show in April and will form part of a presentation at the ISA Trade Show, Hawaii.

My summary? Making sure your equipment is properly configured can’t be bad. No more, no less.

Chris

Treemagineers – all for the trees and none for a fall!

I think we are not so apart on this one! But my answers to your points have to be ‘Jein’ i.e. neither Ja nor Nein!

In the ‘Ropes and Friction Hitches Used in Tree Climbing Operations’ document that you refer to it states under ‘Testing Setup and Procedures’:

‘At an early stage in the testing it was established that a single [attachment] karabiner was the weakest link in a typical doubled rope system. Once this had been established, the climbing line termination (typically a bowline) and friction hitch loop were placed directly into the 16mm shackle on the ram and load cell. Friction hitches that required a separate karabiner were set up as in the field, the friction hitch being attached to one karabiner and the climbing line to another. Alternatively, the climbing line was terminated in a bowline and anchored directly to the shackle.’

This suggests to me that the above research and ours have tested karabiners in different ways. We found that HMS shaped karabiners were, on the whole, better at tolerating wide loading than Offset D shapes. However, even with HMS ‘biners, there was a significant loss of strength due to wide loading, in particular the placing of half the load furthest from the spine/back. Our ‘bottom line’ was a configured strength of 15kN for 3mins, which is essentially what all Euro PPE is required to meet. Some of the combinations we tested did not meet that standard.

Because of these results, and further tests on karabiners used in a choked configuration, we set about trying to come up with a simple system where the karabiners were configured how they are designed for testing, hence the Hitch Climber pulley is part of a system.

[Treemagineers have presented the results of various karabiner tests at an arborists gathering in Augsburg, Germany and at TCI and/or ISA for the last three years. My goodness you must be bored of hearing that stuff by now!]

Your point about karabiners being fine for typical forces is, of course, correct. We just thought it couldn’t be a bad idea to try to cater for those occasions when things go a bit ‘Pete Tong’.

Something worth bearing in mind is quality assurance in the manufacturing process. All of the connectors we used in our tests were from ‘reputable’ manufacturers. Over the last few years I have heard of tests on ‘other’ karabiners where the breaking load was down as low as 9kN (quoted as 22kN+). These tests were ‘best case scenarios’ i.e. 12mm pins at each end of the connector. And before you all jump down my throat saying that I am scare mongering, I am not. The issue is real. This scrap metal is more widely available than you may think. And no, I won’t be drawn into giving names…..for very obvious reasons. So please don’t ask! A bit of brand loyalty may not be silly!

A discussion later in the FC document (which follows the failure of a doubled rope test of a four coil Prusik at a peak force of 2223kg) says:

‘If both the lifeline and friction hitch are connected to one karabiner, the karabiner (minimum 22kN BS) is the weak link, but a substantial 22:1 safety factor was recorded.

The only point I would pick up on here is that you have used the mass of the ‘climber’ as the basis for your calculation of the design factor. If the peak force generated in a fall were used, the design factor would be much smaller. In these situations, the poor configuration of equipment can be quickly exposed.

Our testing shows that the Petzl OK used as the main attachment ‘biner in an HC system with stitched OP e2e slings has a configured strength of ~28kN (~6200lbs). All the other components are also used as designed and tested.

Re the specification of hitch cord, the FC report suggests:

….there is much scope for specific cords to be designed with suitable strength (1700Kg would be ample), but with high external heat resistance and good knotted strength. For example, a cord with a braided core of polyester and a jacket of aramid fibre would, theoretically, solve the problems associated with residual knotted strength and heat resistance.

I note your point in your post that there is scope for heat resistant fibres in the hitch cord mantle to cause heat damage to the climbing line. You are correct, but this must not happen, and responsible safe climbing will take care of this issue.

At the start of our hitch cord testing, we thought that abrasion resistance was the key parameter for hitch cord. But with the switch to smaller diameters (climbing line and hitch cords), less friction at the anchor and an increasingly sporty climbing style, this is perhaps no longer the case. If a ‘big unit’ decides to ‘swing and dump’ whilst using small cordage, heat is more likely to be the issue than abrasion.

OP is 75% Polyester. The Aramid is in the right place for when/if you may need it. Our running rope/heat resistance tests indicate a large safety reserve is provided by the Aramid component, when compared to pure Polyester hitch cords. The aramid protects the polyester from most of the heat build up, so that the Polyester can continue to provide grip for longer. In this way, pricey cords with a ‘hi-tech’ component can be very good value for money when compared with cheaper, lower performance cords. This info was presented at the Augsburg Show in April and will form part of a presentation at the ISA Trade Show, Hawaii.

My summary? Making sure your equipment is properly configured can’t be bad. No more, no less.

Chris

Treemagineers – all for the trees and none for a fall!

NickfromWI

Participating member

- Location

- Los Angeles, CA

Rupe- I'll trade you your HC pulley for something!

love

nick

love

nick

- Location

- Basel, Switzerland

I'd just like to add ne point to Chris' post on the issue of build up of heat.

Based on the results of the tests we presented in Augsburg and will be showing - as Chris already mentioned - in Hawaii, one of the issues we were looking at was the way different friction hitch cord materials behave under a constant load at a constant speed on repeated descents of a defined height.

It'd be going over the top to run through all the findings here, but to me one of the really interesting aspects of the repeated descents was the aspect of descent speed . The descent speeds were 1m/sec, 2m/sec and 3m/sec.

Before the test series I found it hard to picture the speed of descent. Well, let me put it like this: 1m/sec is a speedy descent, 2m/sec is a bail out/emergency exit out of tree/ really fast jump. 3m/sec is out of control, with the hitch fully released. Not pretty seeing a 50kg weight hurtling down from 20m at this speed !

I would consider the 1m/sec descent speed a reasonable speed for a speedy descent. After descents at this speed on the Ocean Polyester slings we saw no visible heat damage to the climbing line.

On the faster descents (2 and 3m/sec) there was localised damage (i.e. glazing), especially on the parts of the line where the hitch braked the descent of the load. But as I said before, I would definitively consider such a descent speed neither to be in compliance with best practice standards, nor to be advisable!

Based on the results of the tests we presented in Augsburg and will be showing - as Chris already mentioned - in Hawaii, one of the issues we were looking at was the way different friction hitch cord materials behave under a constant load at a constant speed on repeated descents of a defined height.

It'd be going over the top to run through all the findings here, but to me one of the really interesting aspects of the repeated descents was the aspect of descent speed . The descent speeds were 1m/sec, 2m/sec and 3m/sec.

Before the test series I found it hard to picture the speed of descent. Well, let me put it like this: 1m/sec is a speedy descent, 2m/sec is a bail out/emergency exit out of tree/ really fast jump. 3m/sec is out of control, with the hitch fully released. Not pretty seeing a 50kg weight hurtling down from 20m at this speed !

I would consider the 1m/sec descent speed a reasonable speed for a speedy descent. After descents at this speed on the Ocean Polyester slings we saw no visible heat damage to the climbing line.

On the faster descents (2 and 3m/sec) there was localised damage (i.e. glazing), especially on the parts of the line where the hitch braked the descent of the load. But as I said before, I would definitively consider such a descent speed neither to be in compliance with best practice standards, nor to be advisable!

Thanks for the detailed reply Chris. That must have kept you out of trouble for a while.

I'll try to explain myself some more:

100kg is the standard load test used in industrial testing. Anything else is meaning less because this is the benchmark for other items in the safety system (EN standards). The MBS of the karabiners was 22kN. This is how the 22:1 safety factor is derived. For those that don't know, 6kN is the limit of force to be experienced in a work at height system in EU.

The karabiners were failing at their rated strengths, because the prusiks and knots used in a DdRT system were holdng out so well (phenomenally well).

Accounting for more than 8kN in real life (absolute max) is fairly futile, as the body is long beyond its 'best before load limit', and rapidly approaching its 'expirey load limit'!

Therefore, the 15kN you mention, has a built in safety factor to account for safety over time (material degradation) and rescue. This is more important for textiles than hardware. Normally, Karabiners will not weaken with time for this to be an issue.

As in rigging, safe systems consider cycles to failure and the weakest link. In a typical DdRT climbing system, this is extremely unlikely to be a properly aligned karabiner, but very likely to be the climber. I won't go into the issues of 'Sporty' climbing encouraging 8kN loads.

With regard to the hitch cords, the burns I have witnessed on my own ropes were from long descents - a hot spot develops over time. It can also easily happen with 'sporty' climbing.

The prusik research and my climbing style is based on seperate, properly aligned karabiners for hitch and terminating the lifeline. This is the same as the hitch climber, only obviously clipping to the same attachment ring, rather than the hitch climber/mickey mouse. This gives many advantages similar to the hitch climber, and some more.

Clipping all life support into 1 karabiner that isn't an HMS, creates high loads on the nose. I'm sick of pointing out to climbers that a klettersteig krab is not an HMS and is the worst of the lot in this situation (and not exactly getting thanked for it

). It still wouldn't reduce the load to 8kN though (i.e the human body will be at huge risk).

). It still wouldn't reduce the load to 8kN though (i.e the human body will be at huge risk).

The real issues are:

1) Climbers obsessed with speed and style, abusing slack management in their systems, climbing above an anchor point, jumping around when tied to a small anchor point, creating situations that can easily generate forces sufficient to seriously damage their health for the rest of their life should they get it wrong and the equipment doesn't fail.

2) A blatant disregard for the above, as long as they look 'Cool'.

3) Lack of knowledge on the work site of what a safe system of work is (reliance on Breaking Strength without understanding limitations and configurations).

I expect you'll agree with some of that. Which again shows how far we have to go as an industry before we see competence in professionally managed risks on the work site (i.e. skilled and knowledgeable supervision).

FWIW, My points are:

1) A hitch climber can help reduce weakening forces on karabiners, but other systems do just as well.

2) The karabiner reduction in strength is still sufficient compared to the 6kN that our systems are designed for, let alone what the body can withstand (i.e. karabiners are not the weakest link)

3)Climbing 'sporty' (recklessly?) in a 'work positioning' sysem, is much more of an issue to health & safety than either of the above (capable of creating 'fall arrest' system forces).

As for presentations around the world, i feel there are much more cost effective and environmentally friendly ways of presenting important information to the everyday arborists that need it.

I'll try to explain myself some more:

100kg is the standard load test used in industrial testing. Anything else is meaning less because this is the benchmark for other items in the safety system (EN standards). The MBS of the karabiners was 22kN. This is how the 22:1 safety factor is derived. For those that don't know, 6kN is the limit of force to be experienced in a work at height system in EU.

The karabiners were failing at their rated strengths, because the prusiks and knots used in a DdRT system were holdng out so well (phenomenally well).

Accounting for more than 8kN in real life (absolute max) is fairly futile, as the body is long beyond its 'best before load limit', and rapidly approaching its 'expirey load limit'!

Therefore, the 15kN you mention, has a built in safety factor to account for safety over time (material degradation) and rescue. This is more important for textiles than hardware. Normally, Karabiners will not weaken with time for this to be an issue.

As in rigging, safe systems consider cycles to failure and the weakest link. In a typical DdRT climbing system, this is extremely unlikely to be a properly aligned karabiner, but very likely to be the climber. I won't go into the issues of 'Sporty' climbing encouraging 8kN loads.

With regard to the hitch cords, the burns I have witnessed on my own ropes were from long descents - a hot spot develops over time. It can also easily happen with 'sporty' climbing.

The prusik research and my climbing style is based on seperate, properly aligned karabiners for hitch and terminating the lifeline. This is the same as the hitch climber, only obviously clipping to the same attachment ring, rather than the hitch climber/mickey mouse. This gives many advantages similar to the hitch climber, and some more.

Clipping all life support into 1 karabiner that isn't an HMS, creates high loads on the nose. I'm sick of pointing out to climbers that a klettersteig krab is not an HMS and is the worst of the lot in this situation (and not exactly getting thanked for it

The real issues are:

1) Climbers obsessed with speed and style, abusing slack management in their systems, climbing above an anchor point, jumping around when tied to a small anchor point, creating situations that can easily generate forces sufficient to seriously damage their health for the rest of their life should they get it wrong and the equipment doesn't fail.

2) A blatant disregard for the above, as long as they look 'Cool'.

3) Lack of knowledge on the work site of what a safe system of work is (reliance on Breaking Strength without understanding limitations and configurations).

I expect you'll agree with some of that. Which again shows how far we have to go as an industry before we see competence in professionally managed risks on the work site (i.e. skilled and knowledgeable supervision).

FWIW, My points are:

1) A hitch climber can help reduce weakening forces on karabiners, but other systems do just as well.

2) The karabiner reduction in strength is still sufficient compared to the 6kN that our systems are designed for, let alone what the body can withstand (i.e. karabiners are not the weakest link)

3)Climbing 'sporty' (recklessly?) in a 'work positioning' sysem, is much more of an issue to health & safety than either of the above (capable of creating 'fall arrest' system forces).

As for presentations around the world, i feel there are much more cost effective and environmentally friendly ways of presenting important information to the everyday arborists that need it.

- Location

- United Kingdom

[ QUOTE ]

Rupe- I'll trade you your HC pulley for something!

love

nick

[/ QUOTE ]

Thanks Nick. What do you have that you think I might want??

Actually, the HC needs a bit more air time, and then even if it doesn't get much use it will stay in the bag of bits.

Are they expensive stateside??

Are we still on 2 dollars to the pound??

Rupe- I'll trade you your HC pulley for something!

love

nick

[/ QUOTE ]

Thanks Nick. What do you have that you think I might want??

Actually, the HC needs a bit more air time, and then even if it doesn't get much use it will stay in the bag of bits.

Are they expensive stateside??

Are we still on 2 dollars to the pound??

- Location

- United Kingdom

"when things go a bit ‘Pete Tong’."

Chris, I think you may have lost some of our American friends with this great use of the English language.

Chris, I think you may have lost some of our American friends with this great use of the English language.

- Location

- United Kingdom

[ QUOTE ]

couple of pics im posting on behalf of pete, he'll be along shortly to explain

[/ QUOTE ]

Me thinks Pete needs to get himself some spliced eyes on his ropes.

couple of pics im posting on behalf of pete, he'll be along shortly to explain

[/ QUOTE ]

Me thinks Pete needs to get himself some spliced eyes on his ropes.

NickfromWI

Participating member

- Location

- Los Angeles, CA

[ QUOTE ]

[ QUOTE ]

couple of pics im posting on behalf of pete, he'll be along shortly to explain

[/ QUOTE ]

Me thinks Pete needs to get himself some spliced eyes on his ropes.

[/ QUOTE ]

I was thinking the exact same thing.

Who is Pete Tong?

I haven't looked yet to see what the HC costs around here. According to the Sherrill catalog, it's $60 and won't be available until June.

love

nick

[ QUOTE ]

couple of pics im posting on behalf of pete, he'll be along shortly to explain

[/ QUOTE ]

Me thinks Pete needs to get himself some spliced eyes on his ropes.

[/ QUOTE ]

I was thinking the exact same thing.

Who is Pete Tong?

I haven't looked yet to see what the HC costs around here. According to the Sherrill catalog, it's $60 and won't be available until June.

love

nick

- Location

- United Kingdom

The Pete that Steve is talking about is not the same Pete as Pete Tong, thats just an extra confusing coincidence.

www.petetong.com

I bet your still none the wiser!?

www.petetong.com

I bet your still none the wiser!?

I've been getting used to the hitch climber, and up until yesterday I thought I had adapted well to it. I had been using it with my longer climbing rope which has a spliced eye, but I was felling trees roadside so i decided to use a shorter rope without. As per usual I tied a double fishermans and set about my days work.

I got a bit of a suprise when I dropped about 8ft down the stem, until I grabbed both ropes!!!

Due to the proximity of the hitch and the termination knot the double fishermans was releasing the friction hitch (see the pics steve posted, thanks for that).

This is a great piece of kit IMO, I love how tidy it makes the system and tends, but people should be VERY carefull of using it with termination knots.

I got a bit of a suprise when I dropped about 8ft down the stem, until I grabbed both ropes!!!

Due to the proximity of the hitch and the termination knot the double fishermans was releasing the friction hitch (see the pics steve posted, thanks for that).

This is a great piece of kit IMO, I love how tidy it makes the system and tends, but people should be VERY carefull of using it with termination knots.

New threads New posts

-

test

-

Free CEUs: February 05 & March 05 - 'Urban Forestry Today' Webcasts @ Noon (Eastern)

- Started by UFT

- Replies: 0

-

-

-

-

-