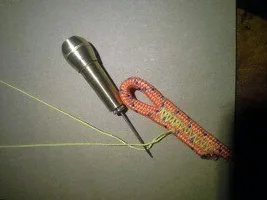

For whatever it might be worth, I have been sewing some tight eyes, and I have a slightly different, but perhaps complementary, approach...

-- I use about a 6 times the rope diameter sew length. (It is a diminishing function, and the "official" number is five times....)

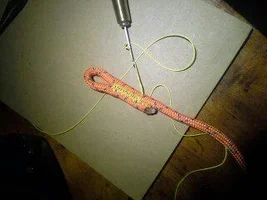

-- I make an eye that is just big enough for another tight eye of the same rope to pass through it.

-- Begin by using a zig zag (sailmaking) sewing machine (very handy for lots of stuff -- adding to your harness, making sewn slings... they're around for pretty cheap if you don't need room under the arm) and sew the meeting between the two parts at about 30 plus stitches per inch -- is like a "bar tack" only narrow, about 3/8" wide (first layer) but grabs both sides and holds everything.

-- Then use 300 lb Dyneema (Braided Fishing Line) Pink or Bright Yellow (so that you can later see an issue if you cut at the eye and don't know it) and begin in the standing side at the outer end, pass the "thread" through, and do a zig zag lock stitch with a frequency of about 5 mm (kinda 6 stitches per inch). You need a piece about 7 to 8 feet long.

- Sew to the middle of the rope. Use needle nose pliers to tighten stitches. (Bury the stitch lock in the middle of the rope, or as close to the middle as you can get it -- no locks anywhere you can see them) up to the throat of the eye.

-- Then sew back, zig zag on top of your first set of stitches, running the needle through slightly outside (slightly toward the outer edge of the rope on each side) and halfway between each stitch of the first set. The stitching will thus "fill in", be continuous (although zig) but not be too "rounded up".

-- When you get back to the outer end of the paired rope, tie a double surgeon's knot in the last little bit of cleft between the two ropes. Then take a "Weller" soldering iron / melter and melt the two ends of the thread knot into the melted end of the rope that is there. The knots stay "inside" between the ropes.

-- I am now wrapping these in Scotch 35 green electrical tape. But of course you can use shrink warp or shrink wrap with glue inside if you want. The only advantage w/ electrical tape is that if you run the splice over something sharp by accident, you can peel the tape to see whether you cut anything you didn't want to.

-- I believe tight is good, but that there is such a thing as too tight in the stitching. In the end, these are stiff, but they are not completely unbendable. As observed elsewhere here, slight irregularity in the sewing I believe is good.

-- I think of this as "lashing" as much as sewing. But I don't go to the outside of the rope (too easy to injure the thread out there) and I end up with something "flat" across the two rope parts. I believe that the locked stitches zigging on top of each other would survive a pretty nasty cut, but I would never hook up a rope to use with even one loose thread.

-- Foolish though I may be, I have confidence that these eyes are strong enough for what I use them for. I worry about everything, but I don't worry about these very much.