Muggs

Been here much more than a while

- Location

- Canuckistan

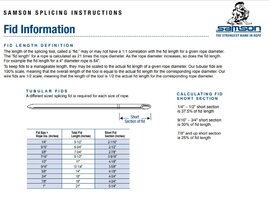

I'm making a dead-eye sling, Beast ring on 7/8" Tenex. I have found many different recommendations for the length of the buried tail after the brummels. Last year I dissected a professionally made sling in 5/8" and I think the buried tail was only about 10 or 12 inches or so, much shorter than I would have expected. My assumption is that when the sling is installed on the tree in a cow or timber hitch, that all the strength is coming from the 2 brummels and very little if any of the strength is based on the tail bury beyond the lock stitching. This might be different if you were just loading the sling straight, end to end. So my question is, does the length of the tail bury after 2 locking brummels actually affect the strength of the sling very much, and if so, what is the proper minimum length bury for a rigging sling like this?