Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

why there is no information on Echo CS2511 muffler mod?

- Thread starter erwin

- Start date

the exhaust has been cut as you will see in the photos.

this to remove the inner part containing the honeycomb catalyst.

I removed the catalyst to prevent its fouling with carbon gases do not change the flow of gas over time but also to facilitate the flow.

the two outer parts were then welded and the original outlet sealed by welding so that the gases relax at maximum in the exhaust and exit the opposite of the gas inlet in the silencer.

and finally a hole made best with the welding of a 13mm stainless steel tube inclined inner diameter to direct the gas where I machined the plastic housing and the tube slightly flattened to have an opening of about 60 to 70% of the entry into the muffler.

the welding was done at tig and it was very difficult because the stainless steel sheet of the silencer is extremely fine.

brazing might be more appropriate.

I attach you photos in illustrations if I can

cordially

Joseph

TimBr

Official Well Known Greeter

- Location

- Northern Virginia

This ain't no GQ fashion show.....

You may have just invented a new fashion trend, if the GQ folks gets a hold of this idea. Guys walking down the catwalk with tiny little Echo 2511's in their hands, modelling the latest in fall lumberjack fashion.

TimBr

Official Well Known Greeter

- Location

- Northern Virginia

Hey, @Jo58 ! Your first name is Joseph, correct? My name is Tim. Welcome to the TreeBuzz forum! I think you are going to like it here!

Nice job, managing to post photos of what you are doing, on your first outing here at the TreeBuzz forum! I'm no saw expert, so I'm not sure exactly what the photos are trying to convey. It is nice of you to make the effort, though, so that the folks that have more knowledge than I can see what it is that you are talking about.

My main reason for this post is simply to welcome you to the forum, and to thank you for signing up to be a member. It is a great community, and I think you will benefit from being a member, just as I have. I look forward to reading more from you. Also, I'd love to see some photos of the tree work that you do in France, if you ever have the time and inclination to take them. It is really cool that this is a world wide community. Take care.

Tim

Nice job, managing to post photos of what you are doing, on your first outing here at the TreeBuzz forum! I'm no saw expert, so I'm not sure exactly what the photos are trying to convey. It is nice of you to make the effort, though, so that the folks that have more knowledge than I can see what it is that you are talking about.

My main reason for this post is simply to welcome you to the forum, and to thank you for signing up to be a member. It is a great community, and I think you will benefit from being a member, just as I have. I look forward to reading more from you. Also, I'd love to see some photos of the tree work that you do in France, if you ever have the time and inclination to take them. It is really cool that this is a world wide community. Take care.

Tim

hello tim

thank you for your welcome.

I am among you to share with everyone the experiences that I realize.

if it can help someone, I would love it.

and I also hope to learn from other friends of the forum.

I will try to send you some pictures of the work but I am not professional so I would do what I can.

have a good day

joseph

for information, I write in English but I also use a translator if my remarks are too complicated and apologize if the translations are sometimes of poor quality.

thank you for your welcome.

I am among you to share with everyone the experiences that I realize.

if it can help someone, I would love it.

and I also hope to learn from other friends of the forum.

I will try to send you some pictures of the work but I am not professional so I would do what I can.

have a good day

joseph

for information, I write in English but I also use a translator if my remarks are too complicated and apologize if the translations are sometimes of poor quality.

SomethingWitty

Arkansawyer

- Location

- LR

That was a lot of work just to open the muffler.A last

I dealt with something similar on my CS400.

Was it worth it?

Rob Stafari

Participating member

- Location

- Cincinnasti

It is always worth it to get the CAT out of the muffler. Unnecessary weight on the saw and unnecessary heat retention right next to the cylinder. Standard operating procedure on the makita 6421s.

As far as max RPM, every saw (even amongst the same model) will respond a little different. Don't know if that little bugger has a limited coil or not, as that can change tuning a little bit, but generally best to tune any saw in the cut. When set rich(needle turned out allowing more mix through) there will be a sort of burbling sound the chainsaw experts call 4 stroking in the cut. Slowly turn the high in and test cut. You want the 4 stroking out when out of the cut, but to clean up and go away in the cut. If the coil is limited be careful as the sound of it hitting the limiter is easy to confuse with the burbling / 4 stroking sound. As always, it best to be on the rich side even at the loss of a little power.

Hope that translates into something understandable for you. Welcome to the forum.

As far as max RPM, every saw (even amongst the same model) will respond a little different. Don't know if that little bugger has a limited coil or not, as that can change tuning a little bit, but generally best to tune any saw in the cut. When set rich(needle turned out allowing more mix through) there will be a sort of burbling sound the chainsaw experts call 4 stroking in the cut. Slowly turn the high in and test cut. You want the 4 stroking out when out of the cut, but to clean up and go away in the cut. If the coil is limited be careful as the sound of it hitting the limiter is easy to confuse with the burbling / 4 stroking sound. As always, it best to be on the rich side even at the loss of a little power.

Hope that translates into something understandable for you. Welcome to the forum.

Thanks rob stafari

your message provided full of information

I must admit that on the carburettor setting in load (in the cut) that you explain me, I do not understand everything.

I know that the ECHO CS 2511 is not equipped with a limited ignition.

on the other hand the procedure of adjustment is interesting but I must try to understand it better to implement it.

Cordially

Joseph

your message provided full of information

I must admit that on the carburettor setting in load (in the cut) that you explain me, I do not understand everything.

I know that the ECHO CS 2511 is not equipped with a limited ignition.

on the other hand the procedure of adjustment is interesting but I must try to understand it better to implement it.

Cordially

Joseph

Rob Stafari

Participating member

- Location

- Cincinnasti

Birdyman88

Branched out member

- Location

- Arlington

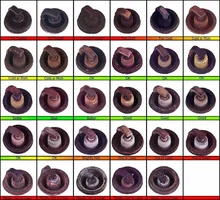

Here are some pics modding my 2511. I did not know if it was the cat or non-cat so I cut a 5/8 hole in the back over the cat area. No cat, and mine had "2541" stamped on the deflector. The middle plate was in there, but it had 3x 17/64 holes where the cat would normally reside. I measured the internal exhaust output area at piston at .225 sq-in. The 3x 17/64 holes were only 73% of that, so I hogged out that whole area. Next, I wanted the exit port to be 100% of piston exit so I could put spark screen back in, so I enlarged exit port to .5"x.5" with rounded corners. Last, I went to Lowes and bought a 5/8" stainless plug to put in the hole I made and a buddy of mine will weld for me. Haven't tested yet, but with no cat and being naturally open stock, I know why this saw runs good with only a mild mod to the exit port.

Joeybagodonuts

Participating member

- Location

- Boondocks

if someone has information on the maximum speed at which we can adjust the machine once the pot changed without risking a break engine, I thank him in advance.

Actualy it is set at 13500 rpm

have a lovely day everybody

So..... Is this where we go ahead & completely modify in a way that requires a tuning & but then worry about how it's going to run after because we don't know how to tune it??? I'm so lost here.. this stuff really is 101..

chiselbit

Been here a while

I put the screens back when I’m done porting a muffler. I live in California which seems to be on fire about half the time. I do NOT want to start a fire. My saws are legal and they run greatDoes everybody take their spark screens out whether their modding their saw or not?

I see pros but are there any cons besides voiding warranty and not being compliant with emissions?

TreeVB

Branched out member

- Location

- Boise, Idaho

Didn't read all posts but if it hasn't been stated yet, change out your sprocket to whatever the pitch is that the still 150's run (sorry but I'm not good with the technical specs. I just run them). Then run the 150 bar. That in combo with even a slight muffler mod and carb adjustment does wonders.

New threads New posts

-

test

-

-

-

-

-

Light 14 or 16" narrow kerf bar for 200t or 201t

- Started by southsoundtree

- Replies: 9

-