robinia

Participating member

- Location

- Ontario, Canada

I recently replaced a warp speed bridge on one of my saddles. I was starting to get concerned about it as it had been in service for at least 2-3 years, occasional usage. I honestly can't remember how old it was.

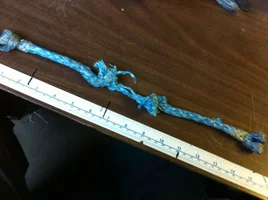

I pulled off the cover to inspect the load bearing core and it looked like you would expect- fairly compressed, a bit ratty looking, but otherwise fine. (see photos)

I then had the old one broken to see what the actual residual strength was.

Pleasantly surprising results: 6,047 lbf compared to the new, unused rating of 9,000 lbf.

However that is a 30% decrease over that time. Probably caught it pretty much right on time.

Looks like there was lots of meat still there after all, and people can draw their own conclusions - I'm only posting this for information.

If you don't trust the gear anymore, switch it out!

I pulled off the cover to inspect the load bearing core and it looked like you would expect- fairly compressed, a bit ratty looking, but otherwise fine. (see photos)

I then had the old one broken to see what the actual residual strength was.

Pleasantly surprising results: 6,047 lbf compared to the new, unused rating of 9,000 lbf.

However that is a 30% decrease over that time. Probably caught it pretty much right on time.

Looks like there was lots of meat still there after all, and people can draw their own conclusions - I'm only posting this for information.

If you don't trust the gear anymore, switch it out!

Attachments

Last edited: