Little bit of fab work anything is possible.

So I'm gonna make my own.

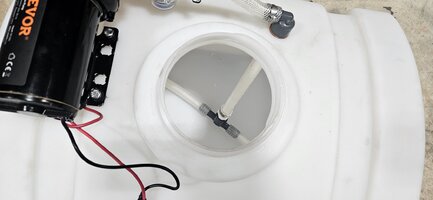

Got a 12V pump.

Found a

Milwaukee M18 battery holder with a stepdown converter - so hoping the 6 or 8mAh High Output battery will be able to power it. If not, I'll figure out mounting a small car or large mower battery.

Bought a

16 gallon tank with a nice 12x22 footprint.

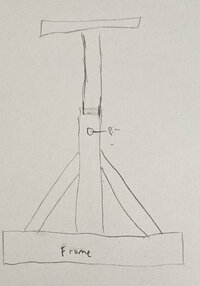

I'll get some angle iron and make a frame to hold it, welded to this hitch (but flipped over):

It is a receiving hitch, so I'll have a straight piece of square tube that will fit into the hitch on the truck and into this hitch (pins on both, obviously.)

I think I'll plumb it very simple with one pipe into the pump. The electric pump has a pressure switch, so I don't think there is any need to have a bypass (I'll just cycle through the hose to mix it). Planning to put a new hole at the very bottom of the tank so I still have the included drain to empty the tank if needed. Will only use about 15-20' of hose as the whole point is we'll bring the sprayer to the tree.

Then to make it portable, I'm thinking something along the lines of a removable handle coming up..not unlike Arbor Trolley's handle - but not at the angle. From there, it will be like a hand truck with just 2 wheels. I could make the handle so it has a bend and the horizontal piece fits into the hitch receiver, but then I wouldn't have the handle to help get the unit into the hitch for transport. I'm picturing the handle on the back side. I haven't completely figured that out yet. I also haven't figured out getting the unit onto the truck...15 gallons weighs a little over 120 pounds. Probably gonna have another 30-40 lbs in everything else. So lets call it +/- 175 pounds that's a little bulky. Doesn't sound like something I want to dead lift to get it onto the hitch. Maybe a light duty trailer jack mounted on it??? Would have to hold the sprayer to balance it, but the lifting would be easy. I also though about a static drop down leg - lean the whole thing back, drop a leg in the front, tip it up onto that leg and into the hitch. But I cannot quite get that to work right in my mind, so in real life is probably less realistic!

I should have less than $500 into it (not including battery and 3/8" hose (wouldn't add much anyhow), which I already have). This will have a bigger electric pump than the unit

@The Green One linked above for less than half the cost - plus some entertainment doing the build!.

so far:

$135 for the tank

$50 for the pump

$20 for the battery holder/converter

$42 for the hitch receiver

$20 for quick connect hose to spray gun fittings

$35 for

adjustable spray gun

$20 for 10" pneumatic wheels from HF (I already have them that I'll take off a small go cart my son and I but that he's since outgrown, but included price here anyhow)

$5 square tubing (also have in my scrap stuff, but included)

Need to buy:

Angle iron

Thin steel strap or ratchet straps to hold the tank to the frame

Pipe or square tube to make the handle.

Plumbing fittings