- Location

- Sarasota

My loader has DPF issues. Was considering a miniskid with tree grapple to feed the chipper. I noticed many of the miniskids don't have power rotation with their grapple. I wonder what setup I should buy for chipper feeding.

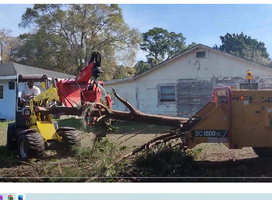

Pictured is my existing set-up. I wonder if the mini would have better visibility and be more efficient at times.

thanks

Pictured is my existing set-up. I wonder if the mini would have better visibility and be more efficient at times.

thanks