- Location

- Ontario, Canada

These aren't redwoods up here, a large tree would be 30 inches DBH give or take.

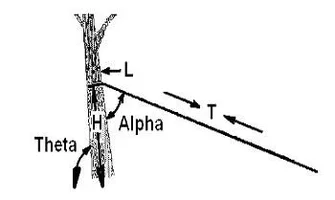

If you get the rope up high and don't leave a large hinge, put the hinge back and continue cutting the forces aren't that great.

If you keep the hinge ahead of center and leave a large hinge then the forces will be greater much greater.

You can have rope slip on the GRCS if things aren't done right so the rope puller will slip much sooner.

There are ways to reduce the force and that's what needs to be done.

If you get the rope up high and don't leave a large hinge, put the hinge back and continue cutting the forces aren't that great.

If you keep the hinge ahead of center and leave a large hinge then the forces will be greater much greater.

You can have rope slip on the GRCS if things aren't done right so the rope puller will slip much sooner.

There are ways to reduce the force and that's what needs to be done.