Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideas for a orginzed shop

- Thread starter fordman

- Start date

boreality

New member

- Location

- boreal forest

I always have to start by emptying everything out to get rid of the junk. Then shelves/drawers. I've got nice shelving racks on wheels from meat shops and bakers. Or commercial kitchens, schools etc.

- Location

- Retired in Minneapolis

Five gallon buckets for big stuff. Cat litter comes in square/rectangular buckets. You can store more stuff in less space than round ones.

Coffee cans, 1-3# size for small stuff.

Check out used office furniture for deals on shelving. Get heavy duty stuff, don't go cheap. Shelves deeper than 24" don't work because you'll 'loose' stuff in the back.

Label the containers and face the labels out all of the time.

Coffee cans, 1-3# size for small stuff.

Check out used office furniture for deals on shelving. Get heavy duty stuff, don't go cheap. Shelves deeper than 24" don't work because you'll 'loose' stuff in the back.

Label the containers and face the labels out all of the time.

- Location

- Decatur, AL

A lesson that was very difficult for me to learn in shop organization was, "if you haven't used it or needed it in the last two years, Get Rid Of It!". Sell it, scrap it, or just give to some other "parts collector". It is sometimes tough, but it really makes a difference in floor and drawer space. And if you ever get to that point where you are keeping 3 broken somethings, so one day you can make 1 running something- throw it all away and go buy a new one.

- Location

- Southern RI

I use those inexpensive (cheap) metal shelves and I assemble the shelves upside down so it has a lip (to keep things from falling off and then I screw them into the roof rafters and hang them down to the floor. If they are not long enough you can cut another one to add on the required lenght to the floor .. Also I buy those plastic masons mixing troughs to keep oil soaked stuff in..

- Location

- Louisville, KY

Shop organization is a state of mind. It takes a lot of work and effort.

Pay attention to your daily routines and how you can make them easier. For the most part, organization should make your life easier. If you do this, then you will maintain that level of organization. If not, then it will fall apart.

In the short term, use bought shelving. However, you may want to build your shelving to suit your specific needs in the future. That is, determine what you need first, then build to suit.

Pay attention to your daily routines and how you can make them easier. For the most part, organization should make your life easier. If you do this, then you will maintain that level of organization. If not, then it will fall apart.

In the short term, use bought shelving. However, you may want to build your shelving to suit your specific needs in the future. That is, determine what you need first, then build to suit.

- Location

- Bangor, PA

Any one want to post pics of their shops to see how they lay out things??? We have been thinking of ways to store and lay out cable and bracing hardware so things can be seen and grab what is needed for the job, rather than digging around to find the stuff.

treebing

Been here much more than a while

- Location

- Detroit, Mi.

limbwalker KNOWS a good shop

- Location

- Everywhere

[ QUOTE ]

limbwalker KNOWS a good shop

[/ QUOTE ]

They KNOW it and OWN it!!!!

limbwalker KNOWS a good shop

[/ QUOTE ]

They KNOW it and OWN it!!!!

mdvaden

Participating member

- Location

- Beaverton. Oregon

[ QUOTE ]

Im on a mission to clean and make our shop more user friendly. Dose anyone have any ideas that work for them?

[/ QUOTE ]

Organizing is something that I have somewhat mastered. It's like a hobby. Let me take the camera outside and see what I can come up with.

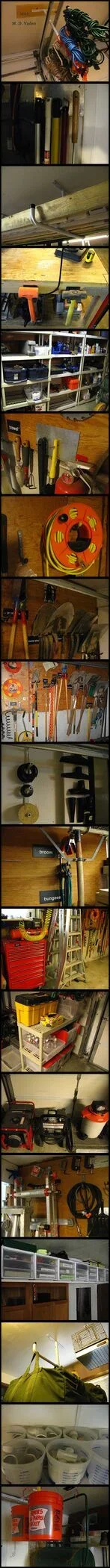

EDIT: back. The hook things on the ceiling are a fave. In 3 photos: the big green bags, the lumber remnants, the ropes and extension cords. Those hooks go up and down, and rotate 90 degrees, which helps if ceiling joists go one way or the other.

Signs -- notice the signs for everything. If shovels and stuff are stripped to bare bones, me or anyone helping knows where stuff goes, otherwise it could be futile. Everything MUST have a HOME for organization to be taken to the limit.

Shop vac on top of rubber squares I use to drop boulders on over sidewalks, is an example of store items of frequent used on top of infrequent use.

The plastic shelves are great, because they allow for occasional reorganizing of main components - big items moving.

Skinny items go with skinny items, like the row of extension handles. Note the trowel --- drilling holes in handles allows items to hang, not lay in drawers. I drill my levels, small sledge handles, etc.. If it can be drilled, it can hang.

Use plywood walls, not sheetrock. Sheetrock limits to just hanging or anchoring to studs. Ply wood means that lightweight and midweight items can fit anywhere. Oh - and don't forget the SIGNS - LOL. Stacking shelves can be shortened, and the same brand extras can be added on top of the taller ones. Light items can go on the tops then. Anchor shelves to the wall if they are tall, with something that will hold the shelf without drilling the resin itself.

Below, is just a thumbnail size. Open the Attachment for the 600 x 8850 single image. Seemed better than 19 attachments in 19 replies.

Im on a mission to clean and make our shop more user friendly. Dose anyone have any ideas that work for them?

[/ QUOTE ]

Organizing is something that I have somewhat mastered. It's like a hobby. Let me take the camera outside and see what I can come up with.

EDIT: back. The hook things on the ceiling are a fave. In 3 photos: the big green bags, the lumber remnants, the ropes and extension cords. Those hooks go up and down, and rotate 90 degrees, which helps if ceiling joists go one way or the other.

Signs -- notice the signs for everything. If shovels and stuff are stripped to bare bones, me or anyone helping knows where stuff goes, otherwise it could be futile. Everything MUST have a HOME for organization to be taken to the limit.

Shop vac on top of rubber squares I use to drop boulders on over sidewalks, is an example of store items of frequent used on top of infrequent use.

The plastic shelves are great, because they allow for occasional reorganizing of main components - big items moving.

Skinny items go with skinny items, like the row of extension handles. Note the trowel --- drilling holes in handles allows items to hang, not lay in drawers. I drill my levels, small sledge handles, etc.. If it can be drilled, it can hang.

Use plywood walls, not sheetrock. Sheetrock limits to just hanging or anchoring to studs. Ply wood means that lightweight and midweight items can fit anywhere. Oh - and don't forget the SIGNS - LOL. Stacking shelves can be shortened, and the same brand extras can be added on top of the taller ones. Light items can go on the tops then. Anchor shelves to the wall if they are tall, with something that will hold the shelf without drilling the resin itself.

Below, is just a thumbnail size. Open the Attachment for the 600 x 8850 single image. Seemed better than 19 attachments in 19 replies.

Attachments

mdvaden

Participating member

- Location

- Beaverton. Oregon

The office (see my previous reply's attachment) shows something I use in the office or the shop area. The plastic storage drawers hold slightly more than an 8.5 x 11 paper dimension. They stack or go side by side. I use them to store different paper, small gadgets, etc.. Because they are transparent, I can basically tell what's in them without having to pull every one open. I tape names inside some of them with printed labels so I know paper, from paper, etc..

Again, the roller on the ceiling had a sign.

The way I did those signs - I had a sign shop put all the names in rows on one or two black sign boards. With enough space between so I could use my small table saw to rip it into small individuals. Then I just use two self-tapping screws to hold each sign. Again why plywood walls are nice. Just anchor light stuff anywhere strongly.

Again, the roller on the ceiling had a sign.

The way I did those signs - I had a sign shop put all the names in rows on one or two black sign boards. With enough space between so I could use my small table saw to rip it into small individuals. Then I just use two self-tapping screws to hold each sign. Again why plywood walls are nice. Just anchor light stuff anywhere strongly.

Attachments

- Location

- Orange, MA

I havent seen others shops, but I'm really digging our setup for organizing cabling gear, and simply takes up one corner of a room, probably 36" high, 60" wide and 24" deep. Spools of cable go underneath, and seperate cubbys on top for eye bolts, thimbles, dead ends and washers/nuts. Then we've just got big plywood boxes we stock up and take out on jobs where we'll be doing a bunch of cables in one day. Wont be at the shop tomorrow but I'll get a shot wednesday if I think of it.

- Location

- Retired in Minneapolis

The rule that I [try] to follow in the shop, and at home:

Don't put it down, put it away.

In my shop there are four, four drawer, letter size file cabinets. This is a cheap way of organizing. One of the cabinets is for nuts and bolts. Quarter inch through half inch in their own drawer. Inside the drawers are parts trays or one pound coffee cans to sort the items. These can be had free or cheap, keep your eyes peeled.

Don't put it down, put it away.

In my shop there are four, four drawer, letter size file cabinets. This is a cheap way of organizing. One of the cabinets is for nuts and bolts. Quarter inch through half inch in their own drawer. Inside the drawers are parts trays or one pound coffee cans to sort the items. These can be had free or cheap, keep your eyes peeled.

tomthetreeman

Participating member

- Location

- Rhode Island

Can someone organize all these ideas into an outline for me? Thanks!

allmark

Participating member

Unfortunately I have used the its on the floor somewhere system for too long. Been working on straightening it all out. It is a frame of mind. When it gets busy it isnt hard to fall back on old habits.

I use old chainsaw files pounded into wood to hang chainsaw chains bars and much more.

I use old chainsaw files pounded into wood to hang chainsaw chains bars and much more.

- Location

- under grace

This seems a little odd to be posting .....since its my shop we are talking about.....but here are some thoughts i have had over the years and have only partially implemented.

Start with what you would like to have in a shop.

a suitable work station for working on saws and all that goes with that.A rope station.Where you keep spools of rope to be cut.You may also store extra blocks,loopies/whoopies here. a vise,grinder,bar rail grinder,and a station for making and sharpening chains.Storage for oil,grease, window cleaner,filters,car wash stuff,wax,rags,wd40,gear lube,and any other liquid that goeas in a truck or piece of equipment for maintenance.Also a clear spot to actually DO the maintenance.A fridge for beer i mean for soda! A good way to organize and store all yard hand tools ; Rakes,shovels,extra pole clips.SO they can be accessed easily and you can quickly tell if something is missing

Start with what you would like to have in a shop.

a suitable work station for working on saws and all that goes with that.A rope station.Where you keep spools of rope to be cut.You may also store extra blocks,loopies/whoopies here. a vise,grinder,bar rail grinder,and a station for making and sharpening chains.Storage for oil,grease, window cleaner,filters,car wash stuff,wax,rags,wd40,gear lube,and any other liquid that goeas in a truck or piece of equipment for maintenance.Also a clear spot to actually DO the maintenance.A fridge for beer i mean for soda! A good way to organize and store all yard hand tools ; Rakes,shovels,extra pole clips.SO they can be accessed easily and you can quickly tell if something is missing

flushcut

Been here much more than a while

- Location

- Delavan, WI

Shelves and label everything

R

rich_h

Guest

[ QUOTE ]

[ QUOTE ]

limbwalker KNOWS a good shop

[/ QUOTE ]

They KNOW it and OWN it!!!!

[/ QUOTE ]

Absolutely agree that the Limbwalker shop is top notch for organization !!! The evolution of their shop as the company has grown has been incredible to watch. I am fully convinced that their unbelievable organization has been instrumental in their growth....

but....

The Kramer Tree Service shop in Chicago is hands down the absolutely most efficient and well thought out shop I have ever laid eyes on...They could easily charge for tours of that spot....

[ QUOTE ]

limbwalker KNOWS a good shop

[/ QUOTE ]

They KNOW it and OWN it!!!!

[/ QUOTE ]

Absolutely agree that the Limbwalker shop is top notch for organization !!! The evolution of their shop as the company has grown has been incredible to watch. I am fully convinced that their unbelievable organization has been instrumental in their growth....

but....

The Kramer Tree Service shop in Chicago is hands down the absolutely most efficient and well thought out shop I have ever laid eyes on...They could easily charge for tours of that spot....

- Location

- Melbourne, Victoria, Australia.

I would love to see a video walkaround of Limbwalkers or Kramers

New threads New posts

-

test

-

Can we talk about Municipal projects and the WILD world of bidding them?

- Started by cooperMI4681A

- Replies: 4

-

-

-

tool/chainsaw lanyard attachment options while in a bucket truck?

- Started by Phil

- Replies: 5

-

-