deevo

Been here a while

- Location

- Horseshoe Valley, Ontario, Canada

And the jetstep foot ascender as well! They are a solid manufacturerHarken is making the X-Rings / NOTCH rings now too. Looks like they are going to the trees now! LOL

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

And the jetstep foot ascender as well! They are a solid manufacturerHarken is making the X-Rings / NOTCH rings now too. Looks like they are going to the trees now! LOL

Harken is making the X-Rings / NOTCH rings now too. Looks like they are going to the trees now! LOL

Correct. It was an Italian company that was rebranding and made the first 38*28 for him. Now that NOTCH/Sherrill/TreeStuff is involved, they let him stay in on the design side of things. He opted for deeper/longer shoulders from what I was reading. They also let him keep the 38*28 beast X ring labled as such instead of NOTCH.And the jetstep foot ascender as well! They are a solid manufacturer

I'm not 100% on this theory of mine, but here it is. I think Notch is taking some of the small companies, and making them offers to help with buying power and getting it to the masses. I know some of us in the industry look at them as the Walmart of the arbor industry (not necessarily a good thing) - in an instance like this I really feel it benefits the community as a whole though. I mean from his original design, we now have the thimble and safe bloc. I don't have a use for a thimble yet but I'm looking for an excuse to grab one.I believe that those rings have been around in the marine industry for awhile (before David started calling them X-Rings). We "borrowed" it from them, not the other way around...I could be wrong, but ask David.

I have a sneaky suspicion that most of them would be cost-prohibitive. And not meant to work in the manner that we use our blocks. Can you imagine negative rigging one of those and it getting bound up on the tree. I feel the side materials are a lot thinner than most of the blocks that we use in our industry.I'm kinda surprised Harken hasn't marketed an arborist rigging block. Some of their sailing blocks look nice.

Good read. We certainly all stand on the shoulders of Giants.Everyone here should realize that we benefit from other industries when it comes to rigging. Here is a great article from Master Rigger and Splicer Brion Toss on what he calls "Cross-Pollinated Rigging".

http://briontoss.com/education/archive/miscmarapr00.htm

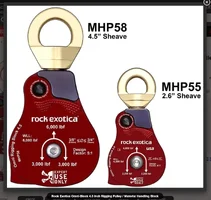

With all the time, effort, design, etc. I feel DMM & treemagineers really hit it out of the ball park with their large and small rigging blocks. I don't see a reason to invest in anything different *yet. Besides course the Rock Exotica Omni blocks with swivels.I mean I'm surprised they haven't engineered and then marketed a suitable arborist block to go along with their arborist winch on the GRCS.

Stiff competition and investment vs return is likely the answer.

You're right, sailing blocks have no business in negative rigging. Not many devices from other industry can handle those kind of forces

Beautiful work!

Its not a GRCS. Its better, and will be around long after the GRCS is in the scrap pile!That looks pretty damn professional, well done!

Wonder if a torque multiplier would have it lifting like a GRCS.

How so?Its not a GRCS. Its better, and will be around long after the GRCS is in the scrap pile!