*useless info*

Participating member

- Location

- usa

i play with numbers on computer,

to verify, decode, extend etc. understandings to functional models

>>so need for math under fire>>have model references, few benchmark numbers , flow of pattern and sense of what is right/wrong building

But, also, to pick apart things to see if that is what i've been reading into them to true that sense;

>>like trying to align my sense of things to their assured actualities

>>to then be able to read and push ahead more confidently.

The new, re-verified sense of aligning most correctly it's own driving force

>>more intentfull , purposeful, non-stalling, confident driving force flow>>clean, not necessarily racing efficiency

>>others follow more easily >>especially when working so well

i always try to find fitting in big picture, partially for cross comparison to understanding AND cross-verifying checksum

>>another way to do this is buy playing it backwards; many solutions like cheating on a maze, found in strategy alone, let alone getting to target of parity check of each some debit/credit against the other

.

Thus, so powerful to me, when find true pivotal key to many questions at once.

.

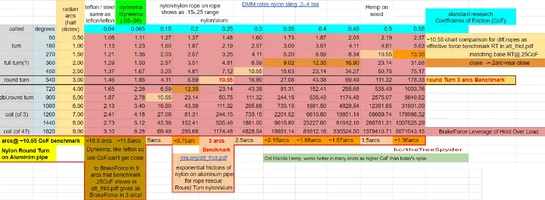

Spreadcheat purports to show Porty etc. brakeForce per half turn, frictions inside of knots etc., and controlling forces of friction hitch over host lifeline etc., also why dyneema etc. are hard to knot,

>>and makes point if same rope and round host mount( materials)

>>ONLY change in turns adjust such a friction force

>>NOT change in rope nor host mount size/friction path(for round on round)

>>larger pipe or branch host mount is for strength AND softer rope arc >>not friction increase

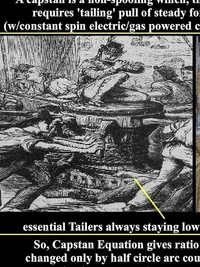

Guess friction is .25 as start point>>remember 3/5/7arcs(half circles) gives ~10/50/250x hold leverage over load as brakeForce and how pattern accelerates (to drop quick on low end, or other materials) and should be golden!

.

>>for nylon on aluminum brake (.25 CoF) for 3half circle arcs 540degrees(RT) on Porty etc.

>>hold 100# @10.55x leverage(per chart) to control load of 1055# etc.

.

Many, many explanations and distinct pattern here.

i've never seen a chart like this, especially of such cross comparatives of verifications and of lessons to big picture too.

Sheet is all setup to self calculate if anyone has other friction coefficients or degrees of contact questions; would be nothing to add to FREE google.sheets

.

Friction coefficients are a set few tho of accepted, engineer stated chart that is much all the same everywhere.

>>but the number can be a guess or interpolation to test!

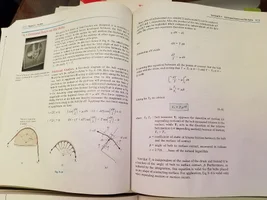

Once again, root work: jrre.org/att_frict.pdf showing for friction brakes in rescue

to verify, decode, extend etc. understandings to functional models

>>so need for math under fire>>have model references, few benchmark numbers , flow of pattern and sense of what is right/wrong building

But, also, to pick apart things to see if that is what i've been reading into them to true that sense;

>>like trying to align my sense of things to their assured actualities

>>to then be able to read and push ahead more confidently.

The new, re-verified sense of aligning most correctly it's own driving force

>>more intentfull , purposeful, non-stalling, confident driving force flow>>clean, not necessarily racing efficiency

>>others follow more easily >>especially when working so well

i always try to find fitting in big picture, partially for cross comparison to understanding AND cross-verifying checksum

>>another way to do this is buy playing it backwards; many solutions like cheating on a maze, found in strategy alone, let alone getting to target of parity check of each some debit/credit against the other

.

Thus, so powerful to me, when find true pivotal key to many questions at once.

.

Spreadcheat purports to show Porty etc. brakeForce per half turn, frictions inside of knots etc., and controlling forces of friction hitch over host lifeline etc., also why dyneema etc. are hard to knot,

>>and makes point if same rope and round host mount( materials)

>>ONLY change in turns adjust such a friction force

>>NOT change in rope nor host mount size/friction path(for round on round)

>>larger pipe or branch host mount is for strength AND softer rope arc >>not friction increase

Guess friction is .25 as start point>>remember 3/5/7arcs(half circles) gives ~10/50/250x hold leverage over load as brakeForce and how pattern accelerates (to drop quick on low end, or other materials) and should be golden!

.

>>for nylon on aluminum brake (.25 CoF) for 3half circle arcs 540degrees(RT) on Porty etc.

>>hold 100# @10.55x leverage(per chart) to control load of 1055# etc.

.

Many, many explanations and distinct pattern here.

i've never seen a chart like this, especially of such cross comparatives of verifications and of lessons to big picture too.

Sheet is all setup to self calculate if anyone has other friction coefficients or degrees of contact questions; would be nothing to add to FREE google.sheets

.

Friction coefficients are a set few tho of accepted, engineer stated chart that is much all the same everywhere.

>>but the number can be a guess or interpolation to test!

Once again, root work: jrre.org/att_frict.pdf showing for friction brakes in rescue

Last edited: