- Location

- Longmont, CO

[ QUOTE ]

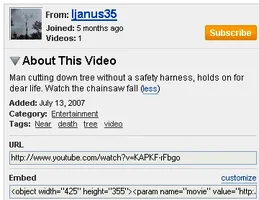

How bout; cut the open face notch, bore cut to set up the hinge, leave a 'strap' to cut with your handsaw, put the chainsaw on your harness and cut the strap with your handsaw?

[/ QUOTE ]

I like that suggestion too Norm. But, most of my tops aren't that big either.

Nevertheless, it would be a safe habit to have when they are that big.

How bout; cut the open face notch, bore cut to set up the hinge, leave a 'strap' to cut with your handsaw, put the chainsaw on your harness and cut the strap with your handsaw?

[/ QUOTE ]

I like that suggestion too Norm. But, most of my tops aren't that big either.

Nevertheless, it would be a safe habit to have when they are that big.