This right here is innovation for efficiency. Nice Sean.I do.

I can get one.

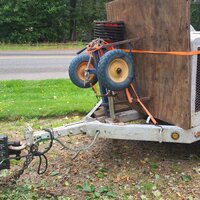

My neighbor welded a slightly/ 10-15⁰ off-plumb, 10" square tube on the center beam of my chipper tongue. I slide the AT cart over the post after removing the AT tongue.

This angle on the welded tube gives me a little more room for my chipper's tongue jack handle movement. If I take off an AT wheel, the tongue jack handle is much more accessible. The V of the trolley matches the direction of the V of the chipper tongue.

I slot the AT tongue through the little triangle of the AT cart.

I ratchet-strap the AT cart to the chipper tongue triangle. Separately, I ratchet strap the AT tongue to the AT or tongue.

I carry (2) 4x4' sheets of plywood between the AT and engine housing. (2) 6x6" wood blocks ride in the basket of the tongue. These are for either blocking up the chipper tongue jack for a low feed-tray height, or used with a handful of screws and plywood to make a 90⁰ chip catcher corner for leaving chips onsite, neatly.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Arbor Trolley - 5 years on

- Thread starter Reg

- Start date

evo

Been here much more than a while

- Location

- My Island, WA

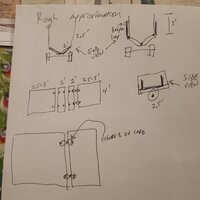

One thing I haven’t gotten around to is cutting some plywood, a few notches and holes for the orange pegs. Kind of a v shaped bottom for the arbor trolly.

This could act as fenders to reduce the random poking thing that tends to rub on the tires and also act as a wheel barrow type cart for moving chips or rakings.

This could act as fenders to reduce the random poking thing that tends to rub on the tires and also act as a wheel barrow type cart for moving chips or rakings.

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

I've considered 'hinges' between 4 pieces of plywood made out of cord, tied in a figure 8 to make a loose material hauler Some simple cord quick-attach between upper plywood and steel stakes.

Doubles as a grinding shield and grinding chip and wood chip catcher, as well as a keeper plant shield.

Previously, I had cord hinges in loops, not figure 8s, between 2'x4' plywood for this purpose.

Probably get to it in the next week or three.

For clarity, I'm guessing the AT to be about 2.5' front to back of the basket, so 4' plywood would extend 16" off the front and 16" off the back.

Also, the 2 4'x4' plywood sheets that I already carry make spinning platforms for the mini, no turf damage from turning.

Doubles as a grinding shield and grinding chip and wood chip catcher, as well as a keeper plant shield.

Previously, I had cord hinges in loops, not figure 8s, between 2'x4' plywood for this purpose.

Probably get to it in the next week or three.

For clarity, I'm guessing the AT to be about 2.5' front to back of the basket, so 4' plywood would extend 16" off the front and 16" off the back.

Also, the 2 4'x4' plywood sheets that I already carry make spinning platforms for the mini, no turf damage from turning.

Last edited:

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

4ish mm cord will do.

From my armchair, I think the figure 8, tied tight, will minimize slop.

A pitchfork helps stabilize the screen in the wind around a grinder. A t-post or sharpened stick will, as well. Might have to involve a zip tie or two.

From my armchair, I think the figure 8, tied tight, will minimize slop.

A pitchfork helps stabilize the screen in the wind around a grinder. A t-post or sharpened stick will, as well. Might have to involve a zip tie or two.

Treemuel

Branched out member

- Location

- Hancock, ME

Anyone try this bag specifically made for the AT?

www.mapleleafropes.com

www.mapleleafropes.com

Stein Arbor-Trolley Multi-Purpose Bag - Lowest prices & free shipping | Maple Leaf Ropes

No..... I don't even have an AT but, I do like MLR. They have a good team there. That bag looks decent, and for $80 it comes with the pockets for stiff inserts. Seems a great deal to me.Anyone try this bag specifically made for the AT?

Stein Arbor-Trolley Multi-Purpose Bag - Lowest prices & free shipping | Maple Leaf Ropes

www.mapleleafropes.com

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

Treemuel

Branched out member

- Location

- Hancock, ME

Thanks! I've got a local welder doing some work for me who could configure something similar. I was thinking just a stub of square tube on the chipper tongue that the AT could sit on and attach to with the regular handle mounting pin.The requested pics.

treegongfu

Branched out member

It is easy to pull in general. Might get into difficulty if the tails are too long as they can prevent you from lifting to the desired height.

My grounds man used to look like a peacock.

My grounds man used to look like a peacock.

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

It's a great tool for narrow access.Genuine question. How easy is the AT to pull when loaded up with brush? One man operation, no winch

If you have wide access all the time and can weld well enough, consider a home build.

I would definitely buy it again.

An electric drill-powered rope puller, which seems to be coming in the scene, attached at the tongue would help with uphills .

You can pull with your truck and redirects, uphill.

Flat land... depends on the terrain smoothness, firmness, strength and willingness to pull harder or more times.

Downhill is a treat.

The foot can be padded for braking on pavement.

I have a piece of thick rope attached the tongue triangle. It can also be redirected through the handle bar area...options.

I tape up the stake tops with bright vinyl/ electrical tape.

Pvc makes good stake extensions.

Treemuel

Branched out member

- Location

- Hancock, ME

Check out the sale at Maple Leaf Ropes right now. Best deal I’ve seen on oneI think I'm sold on one. Been contemplating too long and I'm getting tired of dragging 1-5 branches by hand at a time.

data farm 26

Been here a while

- Location

- Casablanca

Once you learn how to load it, make it balance right, don't have stubs hitting your calf/ankles, etc etc.... it's pretty damn handy imo. Great tool. I like it a lot for use as a wood dolley/ball cart. For some reason we got rid of ours, minimalist style ya know... it's a bit to lug around. But if you have the space it's a no brainer. Actually a kind of intelligence test I'm remembering now. Some folks just couldn't make it work for em and went back to dragging...

data farm 26

Been here a while

- Location

- Casablanca

Don't chip the golf clubs!!!

They've been my go to since before they were an arb supplier. I scour the internet to find small time Canadian suppliers that often have better pricing or free shipping. The number of them I've seen grown into well-known international companies is awesome. What Jason and his team at MLR have done is inspiring. They've become a truly North American presence. Not many Canadian companies get to do that.Check out the sale at Maple Leaf Ropes right now. Best deal I’ve seen on one

Bucknut

Carpal tunnel level member

I thought I remembered someone saying that the tongue of the AT (with handle removed) would fit into a 2” receiver? Then just use a hitch pin to secure it to your chipper or whatever you weld a receiver onto.

I could just try it tomorrow That’s my biggest complaint- storage/transport. It’s heavy, but also a very awkward shape to lift and fit into the back of a truck.

That’s my biggest complaint- storage/transport. It’s heavy, but also a very awkward shape to lift and fit into the back of a truck.

I could just try it tomorrow

evo

Been here much more than a while

- Location

- My Island, WA

Personally I don’t use mine much. BUT glad I have it and I do use it when the time calls for it.I think I'm sold on one. Been contemplating too long and I'm getting tired of dragging 1-5 branches by hand at a time.

I have a couple of walk in beach communities. No haul jobs but think of packing gear for 5/6 city blocks.. makes for one trip.

For me it’s like the GRCS, doesn’t come out it play more than once a month on average. Yet no way in hell I’m getting rid of it.

Yes the peacock tail is a thing.

Lots of creative applications, pegs go in vertical or horizontal

My biggest gripe is lack of wheel shielding, a little rub rub is like a chaffed crack, gets OLD fast

southsoundtree

Been here much more than a while

- Location

- Olympia, WA

Yes, the AT fits and pins in standard 2" hitch tube.