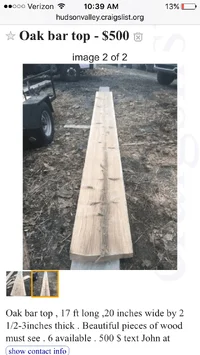

I'm kicking around the idea of picking up a sawmill at some point and wondered if it would be worthwhile. Mainly interested in salvaging lots of interesting crotches that we've been throwing away for years. Rough sawn lumber is cheap but these interesting crotches being sawn live edge 2" thick for bartops, tabletops, etc seem to be bringing a fair amount. Maybe worth even more, for the high end client that reluctantly removed a tree they loved in order to protect their home, to get a unique piece of furniture made from said tree. Just an idea I've been kicking around. Any of you out there doing this? If so, has it been worthwhile?

For my business, this would be something that would be "busy work" on wet days.

I'm open to any ideas you guys have as far as selling a part of a homeowners tree back to them in a different form for a premium price.

Let's hear what you guys think!

For my business, this would be something that would be "busy work" on wet days.

I'm open to any ideas you guys have as far as selling a part of a homeowners tree back to them in a different form for a premium price.

Let's hear what you guys think!