Works wellNew bigger model with D ring. Once adhesive drys (24hrs) I start testing.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D printed throw weights

- Thread starter Whisper

- Start date

- Location

- Western PA

Sounds like some promising progress is being made…

Yes, thanks. Always room for improvement though. The D ring is a good addition over the paracord. Flys well and high for 7.5oz. Moves through tree well. TPU provides resilient tough base without getting in the way ( higher friction ) so the low fiction ABS can slide around easily with being hindered by the TPU. Deadblow effect still needs tweaking but i was using it yesterday quite a bit and prefer it over my other weights.Sounds like some promising progress is being made…

Its very dependent of how things are printed polymer used and infill. But on average it’s about 1.50$ per unit for the plastic for a medium sized unit. But the last piece had 8 components which required a good deal of time for hand construction. So labor is significantly more expensive but I’m working on minimizing that without losing integrity.@Whisper, I'm fairly ignorant about 3D printing. I'm curious about the cost of printing a throw weight. If you don't mind sharing, what's the approximate cost to print the body/shell of one weight?

This is a real R&D project. Many potential possible design routes. Becoming a process of elimination, trial and error, input and Participation by people here with ideas and experiences which unfortunately i find is pretty low on this thread right now.

Please feel free to offer suggestions and input. Its more difficult to do this without experts in the field weighing in.

Please feel free to offer suggestions and input. Its more difficult to do this without experts in the field weighing in.

Since this thread has become so long and wandered in so many directions, a current R&D summary might be helpful.

Seems like this started because your fabric throw weights didn't last. Had the rare earth magnet feature come up. Best fill material. A hand thrown design v. a pneumatically launched design. Dead blow feature. Throwline attachment points.

My impression, right or wrong, is that you're currently sharing different things you're trying rather than seeking input.

Personally, I'm happy with plain old fabric bags. I'd be hesitant to use a hard weight most of the time except for isolation. I am a "let's improve it" kind of person, but with throw weights and lines, plenty of improvement in my skills can occur before nuances in throw weight design become the limiting factor for further improvement. (I am largely satisfied with my current skills, but, of course, I can always become better.)

Seems like this started because your fabric throw weights didn't last. Had the rare earth magnet feature come up. Best fill material. A hand thrown design v. a pneumatically launched design. Dead blow feature. Throwline attachment points.

My impression, right or wrong, is that you're currently sharing different things you're trying rather than seeking input.

Personally, I'm happy with plain old fabric bags. I'd be hesitant to use a hard weight most of the time except for isolation. I am a "let's improve it" kind of person, but with throw weights and lines, plenty of improvement in my skills can occur before nuances in throw weight design become the limiting factor for further improvement. (I am largely satisfied with my current skills, but, of course, I can always become better.)

Hi Dan.

Thank you for your input. I agree this thread has strayed at times. It may just seem like a Journal of my progress but that’s just to keep the thread alive. I want to hear what others would like to see as an improvement on their throw weights. Even just general thoughts and opinions. In the end, if nothing else I hope i will have a throw weight I’m happy with.

I do have a large rare earth magnet stack

Of which there’s a picture somewhere back in this thread. My intention is to make a plastic sheath for it.

Have been throwing the weight last pictured all day and very happy with the results. I think I have been forthright in explaining the materials and processes I’ve used in the preceding posts so I don’t want to bore everyone with going over it again.

Thank you for your input. I agree this thread has strayed at times. It may just seem like a Journal of my progress but that’s just to keep the thread alive. I want to hear what others would like to see as an improvement on their throw weights. Even just general thoughts and opinions. In the end, if nothing else I hope i will have a throw weight I’m happy with.

I do have a large rare earth magnet stack

Of which there’s a picture somewhere back in this thread. My intention is to make a plastic sheath for it.

Have been throwing the weight last pictured all day and very happy with the results. I think I have been forthright in explaining the materials and processes I’ve used in the preceding posts so I don’t want to bore everyone with going over it again.

It's rare that I pull a throw weight back in the direction it was thrown or launched. Too much potential for it to get hung in most situations I deal with. That said, I don't really need this feature (which can be approximated by the way you tie the line to weight): a throw line attachment point that releases with some amount of pull. Not so little that the weight inadvertently detaches all the time, but such that you can pull the line off the weight if the weight gets stuck. Hopefully, the hard sided weight falls once the line is pulled free. If not, at least it's only the weight stuck in the tree instead of the line and the weight.

I'm picturing a 'depress the tab, insert the end of the throwline into the hole' sort of thing. Somewhat like certain terminals for speaker wires. The tab may need to be recessed or otherwise protected against damage.

A consistent throwline end may be needed. A frayed end won't go in a hole and an oversized melted button end may not release. Or you could even have a small streamlined permanently attached pin on the throwline end that gets inserted in the weight. Would eliminate a lot of tying.

I'm picturing a 'depress the tab, insert the end of the throwline into the hole' sort of thing. Somewhat like certain terminals for speaker wires. The tab may need to be recessed or otherwise protected against damage.

A consistent throwline end may be needed. A frayed end won't go in a hole and an oversized melted button end may not release. Or you could even have a small streamlined permanently attached pin on the throwline end that gets inserted in the weight. Would eliminate a lot of tying.

Thank you Dan. If I’m correct what you’re looking for is some sort of break away from the main weight and the line. That right? Give me some time to think about it.It's rare that I pull a throw weight back in the direction it was thrown or launched. Too much potential for it to get hung in most situations I deal with. That said, I don't really need this feature (which can be approximated by the way you tie the line to weight): a throw line attachment point that releases with some amount of pull. Not so little that the weight inadvertently detaches all the time, but such that you can pull the line off the weight if the weight gets stuck. Hopefully, the hard sided weight falls once the line is pulled free. If not, at least it's only the weight stuck in the tree instead of the line and the weight.

I'm picturing a 'depress the tab, insert the end of the throwline into the hole' sort of thing. Somewhat like certain terminals for speaker wires. The tab may need to be recessed or otherwise protected against damage.

A consistent throwline end may be needed. A frayed end won't go in a hole and an oversized melted button end may not release. Or you could even have a small streamlined permanently attached pin on the throwline end that gets inserted in the weight. Would eliminate a lot of tying.

That's right. Where either the bare line pulls out of the weight, or a thingamajig on the end of the throw line that pulls out, which is too small and streamlined to have appreciable snag potential.Thank you Dan. If I’m correct what you’re looking for is some sort of break away from the main weight and the line. That right? Give me some time to think about it.

Problem is there’s a lot of Centrifugal weight on the weight when throwing it. The breakaway would have to be outside that spec, which I think is significant. Once again I’d have to think about it. Unfortunately not all problems can be solved, at least not by me.That's right. Where either the bare line pulls out of the weight, or a thingamajig on the end of the throw line that pulls out, which is too small and streamlined to have appreciable snag potential.

One possible incarnation

I'd want the extraction force to be fairly high, as much as possible while still being able to remove the throw weight from the line by hand in the normal course of things without struggling. 25-35 pounds?? I wouldn't think hand throwing would get near that. Some sort of release button could also be added to allow the pin to come out only when you depress the button or pull quite hard.

The concept could be similar to a slic pin that provides less-than-absolute locking except the tabs are in the body of the weight instead of on the slic pin.

Or maybe a collet like design could be used to allow for easy release when you want to take the line off the weight and adjustable pin extraction force for actual use.

I'd want the extraction force to be fairly high, as much as possible while still being able to remove the throw weight from the line by hand in the normal course of things without struggling. 25-35 pounds?? I wouldn't think hand throwing would get near that. Some sort of release button could also be added to allow the pin to come out only when you depress the button or pull quite hard.

The concept could be similar to a slic pin that provides less-than-absolute locking except the tabs are in the body of the weight instead of on the slic pin.

Or maybe a collet like design could be used to allow for easy release when you want to take the line off the weight and adjustable pin extraction force for actual use.

Last edited:

I’m heading out soon it’s Canada‘s here. I’ll give your plan a good looking out when I’ve got the time. Just off the cuff I was thinking about a tube that the string goes through where all the internal hairs (for lack of a better word) were oriented toward the base. Think of a roll of Astroturf with all the grass pointed in one direction. String the rope down through the tube in its natural direction. Breaking free the string would require some force to bend all the (grass) in the right direction. It’s due to massive surface area that makes this potentially workable. What do you think?

*Canada day

*Canada dayI’m heading out soon it’s Canada‘s here. I’ll give your plan a good looking out when I’ve got the time. Just off the cuff I was thinking about a tube that the string goes through where all the internal hairs (for lack of a better word) were oriented toward the base. Think of a roll of Astroturf with all the grass pointed in one direction. String the rope down through the tube in its natural direction. Breaking free the string would require some force to bend all the (grass) in the right direction. It’s due to massive surface area that makes this potentially workable. What do you think?

What about splitting the pin so it flares out. You would need to squeeze it together to push it into the receiving end? Might be worth a try and possible with my printer.One possible incarnation

View attachment 82662

I'd want the extraction force to be fairly high, as much as possible while still being able to remove the throw weight from the line by hand in the normal course of things without struggling. 25-35 pounds?? I wouldn't think hand throwing would get near that. Some sort of release button could also be added to allow the pin to come out only when you depress the button or pull quite hard.

The concept could be similar to a slic pin that provides less-than-absolute locking except the tabs are in the body of the weight instead of on the slic pin.

Or maybe a collet like design could be used to allow for easy release when you want to take the line off the weight and adjustable pin extraction force for actual use.

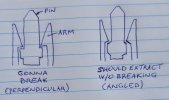

I got ya. I know exactly what you’re talking about. Unfortunately not every idea is printable. The idea is sound yet tweeting it so it can be printed is the trick.I'm picturing tabs or arms more so than hairs. Like the tabs that fasten the halves of many plastic goods together. But don't have the holding surfaces exactly perpendicular to the axis of insertion so the tabs don't break off during extraction.

View attachment 82663

No matter what it’ll be a design challenge. Choosing the correct polymer is just the start but i do think you idea has merit.I'm picturing tabs or arms more so than hairs. Like the tabs that fasten the halves of many plastic goods together. But don't have the holding surfaces exactly perpendicular to the axis of insertion so the tabs don't break off during extraction.

View attachment 82663

How much of a cut do you want? LolNo matter what it’ll be a design challenge. Choosing the correct polymer is just the start but i do think you idea has merit.