Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sticht Hitch

- Thread starter Brocky

- Start date

Christrees

Been here a while

- Location

- New York

Thank you I appreciate it..

@Brocky you have shown several friction reducing options including various diameters of pipe sections, a second ring, a low friction ring, a Spool Shackle, the Petzl Ultralegere, a ball bearing, pieces of rope mantle, and some I don't recognize. In #270 @Lupin_IV recommended the Pinto spacer. How do you rank the performance of these? Is the configuration in post #96 still one of the best?

What became of the configuration shown in #135? Are you using it? Did you find something better?

What became of the configuration shown in #135? Are you using it? Did you find something better?

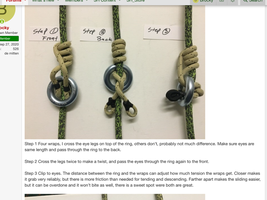

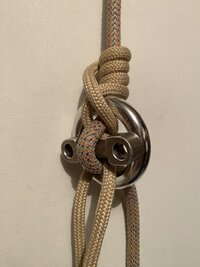

All of those devices work to keep the v shapes on the top and bottom of the twist in back from wedging into the rope when hand tending. However, I found they aren’t needed, I now tie it like #317 using only a piece of hitch cord, for rec climbing. The hitch slides slightly easier with a metal ring, like post #319, better for tree work where it would see more use.

When using spliced or sewn eyes, adjusting the spacing between the wraps and the lower section makes it hand tend easy enough so don’t need anything else. A piece of tubing, or pipe was the simplest and most efficient.

There was too much going on in #135, sometimes use a fig. 8, or tubular now.

When using spliced or sewn eyes, adjusting the spacing between the wraps and the lower section makes it hand tend easy enough so don’t need anything else. A piece of tubing, or pipe was the simplest and most efficient.

There was too much going on in #135, sometimes use a fig. 8, or tubular now.

I've gone through this thread twice and I cannot find illustrations on how to tie that hardware-free version. The front ring is formed from the hitch cord, not a separate soft ring, correct?However, I found they aren’t needed, I now tie it like #317 using only a piece of hitch cord, for rec climbing.

Lignotuber

Participating member

- Location

- Socal

Thanks for sharing! Seems to tend better than the ring versión did for me. Not sure I got the bottom part 100% correct but seems to work good.Yes, I call it the Soft Sticht, passing the ends through the twist makes it compact and keeps the twist from wedging.

View attachment 93731

As I experiment with the hardware version of this hitch and observe the way the front and back rings pinch together I wonder if there is a way to use this effect to include additional descending friction within the hitch itself.

If instead of the hole in the middle of the front ring there was a ribbed friction channel, similar to an ATC XP, the rope would be pressed into that channel and it might provide significant friction. There would need to be slots on either side of that friction channel for the hitch cord to pass through so this would look similar to a Sticht Plate but the slots would be farther apart make room for that channel. Those slots would need to have a large radius like the ring so that the cord could easily slide through them to provide maximum pinching force between the front plate and the rear ring.

If instead of the hole in the middle of the front ring there was a ribbed friction channel, similar to an ATC XP, the rope would be pressed into that channel and it might provide significant friction. There would need to be slots on either side of that friction channel for the hitch cord to pass through so this would look similar to a Sticht Plate but the slots would be farther apart make room for that channel. Those slots would need to have a large radius like the ring so that the cord could easily slide through them to provide maximum pinching force between the front plate and the rear ring.

Last edited:

kludge

Participating member

- Location

- Eastern PA

What you are describing seems most similar to the hitch hiker: https://climbinginnovations.com/hhxf/As I experiment with the hardware version of this hitch and observe the way the front and back rings pinch together I wonder if there is a way to use this effect to include additional descending friction within the hitch itself.

If instead of the hole in the middle of the front ring there was a ribbed friction channel, similar to an ATC XP, the rope would be pressed into that channel and it might provide significant friction. There would need to be slots on either side of that friction channel for the hitch cord to pass through so this would look similar to a Sticht Plate but the slots would be farther apart make room for that channel. Those slots would need to have a large radius like the ring so that the cord could easily slide through them to provide maximum pinching force between the front plate and the rear ring.

You use stopper knots to tie into a “dog bone” which then applies friction to the line by pressing against a backing plate by sliding along slots in the plate. There is a second attachment point that provides friction in a similar manner.

You describe putting more of a bend in the line. The advantage of the plate with slots that allow the friction points to smash against them, is the line does not have to be slack to put a bend into the line. The friction of pinch happens on a straight line.

There are other mechanical devices out there that put more bend in the line.

What you are describing seems most similar to the hitch hiker: https://climbinginnovations.com/hhxf/

You use stopper knots to tie into a “dog bone” which then applies friction to the line by pressing against a backing plate by sliding along slots in the plate. There is a second attachment point that provides friction in a similar manner.

I see the similarity. The use of cam-slots to convert longitudinal load into a transverse clamping force (pinching) requires a large and complicated body and introduces metal-on-metal wear points, but it no doubt allows more pressure. With the Sticht Hitch we're getting transverse pressure merely by redirecting the hitch cord through a ring, acting as an inefficient pulley.

I think a bend in the line will be desirable in practice but that pinching force exists with or without it and the friction channel I describe would not require it. I hope my idea may be part of the continuing development of this light and inexpensive system.

Last edited:

Here is an idea for adding this proposed friction channel to an existing ring rather than creating a plate from scratch.

A rough sketch with the shading representing the V-groove.

- Starting with an aluminum bar of the right size mill or file semicircular grooves on either end of one side so that it nests against the ring.

- On the other side grind out a V-groove in the middle with a cut-off wheel, tapering it to the ends so that it does not cut into the semicircular grooves on the reverse and blending into a smooth area for the rope to run on when it is not bent by the opposing ring.

- Texture the sides of the V-groove with a cone shaped abrasive point, to form ridges for increased friction as on the ATC XP.

- Round all edges so that they do not abrade the hitch cord or rope.

A rough sketch with the shading representing the V-groove.

I found that the slight bend in the rope at the center of the ring causes the hitch to release easier than the pinching when using the solid Sticht plate. Also too much bend at the ring will lock up the rope. The four sections of cord from the twist, or six if tying a stopper in back,also provide friction.

A rope running over a v groove like an ATC won’t grab, like it would with a clam cleat, the ribs aren’t pronounced enough to draw the rope in.

Using tubing , or pipe, the HH can be made a little more compact and softer. This is a working model, a useable version will be aluminum side plates, stainless spine and rings.

Your ring bar is similar to brake bars used on carabiners in the past, they fell out of favor when they started to break the carabiners. I made one that would break before the steel carabiner. It takes more effort to hold your weight than an ATC with a v groove, or figure 8.

A rope running over a v groove like an ATC won’t grab, like it would with a clam cleat, the ribs aren’t pronounced enough to draw the rope in.

Using tubing , or pipe, the HH can be made a little more compact and softer. This is a working model, a useable version will be aluminum side plates, stainless spine and rings.

Your ring bar is similar to brake bars used on carabiners in the past, they fell out of favor when they started to break the carabiners. I made one that would break before the steel carabiner. It takes more effort to hold your weight than an ATC with a v groove, or figure 8.

@Brocky Thanks for sharing more of your designs and experiments. Select replies.

In contrast to both the carabiner brake bar and #333 I am not proposing passing the rope behind or around the bar. Further the long axis of the bar would not be transverse to the rope, instead it would be parallel to it. There would be nothing to reconfigure for a descent. When the hitch is loaded the rear ring would pinch the rope as it already does, but instead of pressing the rope against the large radius of a ring or the flat backside of a Sticht Plate it would be pressed into a V-groove following the path of the rope. If the center of this V-groove is deeper than the ends there will also be a degree of bending which should contribute to the friction.

It is my intent to move friction and wear away from the hitch cord to a metal component.

In contrast to both the carabiner brake bar and #333 I am not proposing passing the rope behind or around the bar. Further the long axis of the bar would not be transverse to the rope, instead it would be parallel to it. There would be nothing to reconfigure for a descent. When the hitch is loaded the rear ring would pinch the rope as it already does, but instead of pressing the rope against the large radius of a ring or the flat backside of a Sticht Plate it would be pressed into a V-groove following the path of the rope. If the center of this V-groove is deeper than the ends there will also be a degree of bending which should contribute to the friction.

This is as I expect as there is no friction channel on the back of the Sticht plate.I found that the slight bend in the rope at the center of the ring causes the hitch to release easier than the pinching when using the solid Sticht plate.

Can optimal friction be found merely by finding the right amount of bend then? Or is it unstable, exhibiting both not enough friction and locking up at different times in the same configuration?Also too much bend at the ring will lock up the rope. The four sections of cord from the twist, or six if tying a stopper in back,also provide friction.

It is my intent to move friction and wear away from the hitch cord to a metal component.

I don't want it to lock up or draw the rope in so this is good? It surely does provide additional friction with only the force I can provide with my fingers.A rope running over a v groove like an ATC won’t grab, like it would with a clam cleat, the ribs aren’t pronounced enough to draw the rope in.

Last edited:

I think understand now, not sure if it would work, a lot would depend on the stiffness of the rope, too stiff and it won’t bend into the v groove, and it won’t wedge as much as getting pinched. The hand tending might take more effort with the additional constant friction.

I agree that a lot could depend on the rope. Even Pit Rope bends in a brake bar rack and I don't think anyone would be using something that stiff so rather than the bending itself I am more concerned with how squish-able the rope cross-section is. If it cannot be pressed fairly deeply into the groove it's not likely to work.

I think hand tending would not be a problem as pulling out (away from the user) opens a gap between the rings. As long as the top and bottom of the friction groove bar or purpose-made plate are kept smooth I anticipate both hand and automatic tending to be largely unaffected.

How did the stacked configuration in #239 behave? Can it be refined further? Have you tried it with a Totem instead of two rings?

I think hand tending would not be a problem as pulling out (away from the user) opens a gap between the rings. As long as the top and bottom of the friction groove bar or purpose-made plate are kept smooth I anticipate both hand and automatic tending to be largely unaffected.

How did the stacked configuration in #239 behave? Can it be refined further? Have you tried it with a Totem instead of two rings?

I got a chance to retry the system in #239, does provide more friction, makes releasing a little easier, but harder to tend, a trade off.

I mostly use the SGBII shown in post #149, on page 8, quick and easy to use on the fly, keeps the rope free to footlock.

A few years ago I came up with a simple device for taking the load off the hitch when descending. It can be added to most hitches if the legs are long enough. I only got to a wooden working model to test if useable, a napkin ring with a butt crack on the side. Works great for the limited testing, can be done one handed, wrap the rope into the groove a compress the wraps while controlling the descent. I need to get a metal one made, but not sure if it would be milled, or forged?

I mostly use the SGBII shown in post #149, on page 8, quick and easy to use on the fly, keeps the rope free to footlock.

A few years ago I came up with a simple device for taking the load off the hitch when descending. It can be added to most hitches if the legs are long enough. I only got to a wooden working model to test if useable, a napkin ring with a butt crack on the side. Works great for the limited testing, can be done one handed, wrap the rope into the groove a compress the wraps while controlling the descent. I need to get a metal one made, but not sure if it would be milled, or forged?

That's a nice compact way to allow direct control of friction from the lower part rather than the cord wraps. Downsides: It looks complicated to manufacture. It requires enough slack in the rope to lift it across that groove. It looks like it would add friction to hand-tending?

I wrote that it would take two hands, then read your post again and you said it only takes one; how does that work?

Does my proposed impinging-ring-and-groove system seem promising from the test in #337? I think it would be comparatively trivial to manufacture a crossbar to fit a common ring size. Even a unified part with slots straddling a groove seems a lot easier to approach than the compound 3D shape you carved in wood as it could be made from plate stock. It could also be produced at scale with hot forging should there be the demand.

I wrote that it would take two hands, then read your post again and you said it only takes one; how does that work?

Does my proposed impinging-ring-and-groove system seem promising from the test in #337? I think it would be comparatively trivial to manufacture a crossbar to fit a common ring size. Even a unified part with slots straddling a groove seems a lot easier to approach than the compound 3D shape you carved in wood as it could be made from plate stock. It could also be produced at scale with hot forging should there be the demand.

Last edited:

For hand tending, the rope only needs to be lifted out and up about 90 degrees, doesn’t enter the groove, it just acts like a piece of tube tender.

To use for descending, lift up 180 degrees for it to go in the groove, and then use a couple fingers to compress the wraps.

Not sure your idea’s extra friction is needed.

To use for descending, lift up 180 degrees for it to go in the groove, and then use a couple fingers to compress the wraps.

Not sure your idea’s extra friction is needed.

New threads New posts

-

test

-

-

-

-

Light 14 or 16" narrow kerf bar for 200t or 201t

- Started by southsoundtree

- Replies: 9

-

-