Eric,

Thanks for putting the video up.

Here are some observations from an arm chair arborist 8,003 miles/12,880 km away. You're in shirtsleeves and we've got 2 inches of snow on the ground.

-I see that you used three-strand rope for the VSL. There’s probably a reason. 3 strand has so much surface friction and it stretches more than double braids. In the short distance that you have it probably doesn't make a big difference though.

-It looked like you used a timber hitch to anchor the VSL. My preference it to do two round turns and tie off with a running bowline. The TH can slip down or unroll a bit when the VSL is loaded and unloaded. Another way to rig the anchor is to tie a clock hitch and use a master link,

http://catalog.thecrosbygroup.com/maininterface.htm, for the anchor. Then the VSL is tied to the ML. If a chunk hits the ML it is very unlikely that it will be damaged. The ML can be slid around the trunk on the clock hitch to have it in the best position.

-It isn't unusual to have at least one 'butt pucker' drop when rigging in tight places. You couldn't have been luckier with your wild drop

Here are some ways to reduce the bad jumps.

***Tighten the VSL.

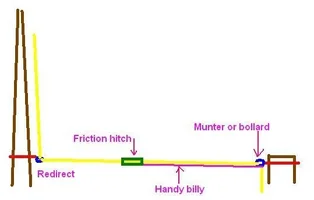

----A Munter on the anchor allows you to capture the slack. Add a piggy back handy billy or come-along and then snub off the VSL.

----Tie a butterfly hitch at about head height. Use this to pull the VSL off to one side if you have a solid anchor. Sometimes a groundie can just put tension on the butterfly. The butterfly can be pulled off in any direction to direct the drop.

***Use as short a sling for the chunk as possible. Depending on where you put the choker, the length of the chunk and the height you can get the chunk to flip and come down flat or on it's butt. Jerry B. has a good description in 'The Fundamentals of General Tree Work."

***Even if you don't tension the VSL with a side pull, a butterfly can be used as a stopper. Biners, snaps and shackles can all be used for the slider on the sling. Adjusting the butterfly up or down can account for a long sling. If you have five feet of lateral space put the butterfly at about five feet or so and the chunk won't jump so far.

***I have NEVER cut a palm so I have no clue about the fiber. Is there a reason that you didn't use a more open face?

***The butt can be leashed if there's a chance that the butt may roll. After the face is cut, choke off a sling above the face and at the butt. The shorter the distance between the two chokes, the better.

***There were a few pieces of trunk wood set on the side above the stairs. We call those a corduroy or backstop. Putting them perpendicular to the log keeps them from rolling or moving if the trunk hits them. They can also act as a bridge to absorb some of the impact too. Laying out corduroy can be quite creative too. I've used longer, smaller diameter pieces on the bottom for bridging and then big pieces as a backstop to cage the trunk. Putting a sloped face on the backstop chunks can help slide the trunk back onto the corduroy.

All in all, it was a fun vid to watch! Too bad about the two topped trees. Are you going to start to reconstruct the top of your client's tree? It looked like there could be hope. The neighbor's could use a ring of cables to add some support along possibly trimming.